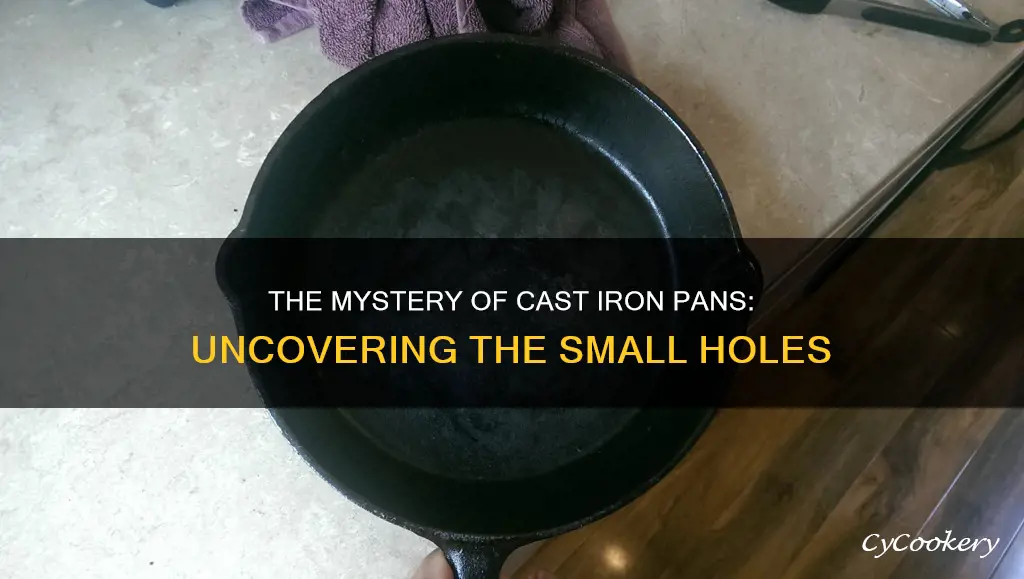

Cast iron pans are known for their durability and longevity, but even these kitchen workhorses can develop defects over time. One common issue that owners may encounter is the appearance of small holes, known as pinholes, in the surface of the pan. These pinholes are typically the result of the manufacturing process and are often caused by the reaction between water vapour and other elements, which leads to the formation of micro gas bubbles. While these pinholes may not seem like a big deal, they can impact the structural integrity of the pan and create food safety issues by trapping food particles that are difficult to remove.

| Characteristics | Values |

|---|---|

| Holes in cast iron pans | Pinholes are a common defect in cast iron pans. They are usually caused by a chemical reaction when water vapour reacts with accompanying elements. |

| Hole treatment | Holes can be patched up. |

| Hole prevention | Holes can be prevented by limiting the risk of air bubbles forming. |

What You'll Learn

Pinholes are a common defect in cast iron pans

Pinholes are generally found scattered across large surface areas, just beneath the cooking surface of the pan. They are considered defects because they affect the structural integrity of the cast iron and can collect food particles, fostering bacterial growth. The presence of pinholes may prompt concerns about food contamination and prompt questions about the safety of using such pans.

The formation of pinholes is a result of specific chemical reactions, primarily involving water vapour and other elements. This interaction triggers the formation of micro gas bubbles, which are then enlarged by hydrogen and nitrogen. Several factors contribute to this chemical reaction, such as excess nitrogen and moisture in the moulding sand, the introduction of excess hydrogen through rusty or oily feedstock, and incomplete skimming of slag during smelting.

To prevent pinholes in cast iron cookware, manufacturers can take several measures to minimise the risk of air bubble formation. This includes altering the feedstock to reduce hydrogen carriers, shortening flow paths to limit oxidation, and addressing issues with the moulding sand and feedstock.

Panera Bread Employee Pay Revealed

You may want to see also

Pinholes are caused by water vapour reacting with other elements

Pinholes are a common defect found in cast iron products, including cookware. These holes are usually visible and can appear as spherical holes or blisters with thin graphite skins. They can also resemble larger, irregularly shaped cavities, sometimes accompanied by spots of oxidation. Pinholes are typically found in clusters over large surface areas, just below the surface of the cookware.

While pinholes may not cause any functional issues, they can affect the structural integrity of cast iron and create a breeding ground for bacteria as food particles can get trapped in the holes and are difficult to remove through normal washing. Therefore, it is important for importers of cast iron cookware to strive to limit pinholes in their finished goods.

Gold Pan: TF2's Costly Commodity

You may want to see also

Pinholes can be a breeding ground for bacteria

Pinholes in cast iron pans can be a breeding ground for bacteria. Pinholes are small holes in the surface of the pan, typically caused by gases escaping during the manufacturing process. While some people believe that the high temperatures of cooking prevent bacteria from surviving in these pinholes, others argue that they can act as tiny crevices that trap food and bacteria, making it difficult to remove them even with effective cleaning.

The concern with pinholes is that once food particles become lodged in them, they provide an ideal environment for bacterial growth. This is because pinholes create a textured surface that is challenging to clean thoroughly. Even with warm soapy water or a dishwasher, it can be difficult to dislodge food particles and completely sanitise the area. This is especially true for pans with a high number of pinholes or large pinholes.

In the food industry, strict guidelines must be followed regarding the types of surfaces that come into contact with food. Commercial manufacturers invest significant time and money in sourcing materials that prevent defects like pinholes, as items with these imperfections cannot be sold as food-safe. The Food Code 2013 published by the FDA stipulates that 'food-contact' surfaces must be made from materials with a smooth, easily cleanable surface and be resistant to pitting, chipping, scratching, and other defects.

The presence of pinholes in cast iron pans can be a cause for concern due to the potential for bacterial growth. While some people may feel that the high temperatures of cooking are sufficient to kill bacteria, others argue that the pinholes can trap food particles and provide an ideal environment for bacterial growth. Proper seasoning of the pan and effective cleaning practices can help mitigate these concerns. However, it is essential to recognise that pinholes can make it more challenging to ensure the pan is entirely free of contaminants.

D&W Pans: Dishwasher Safe?

You may want to see also

Cast iron pans are difficult to completely ruin

Cast iron pans are notoriously durable and can last for decades with proper care. While they can be mistreated, they are challenging to ruin completely. Here are a few reasons why cast iron pans are difficult to ruin:

- Resilience against high temperatures: Cast iron pans can withstand extremely high temperatures without warping or sustaining significant damage. This makes them ideal for various cooking techniques, including searing, frying, and even baking. Even if a cast iron pan is left on a heat source for too long, it will not be completely ruined and can be restored with proper cleaning and re-seasoning.

- Ability to withstand moisture: While cast iron pans should not be soaked, left to air dry, or placed in the dishwasher, they can withstand moisture to a certain extent. If a pan has been exposed to moisture and developed rust, it can be restored by scouring the surface, applying cooking oil, and baking it in the oven to restore the seasoning.

- Ease of re-seasoning: The seasoning on a cast iron pan can break down over time, but it can also be easily restored. Re-seasoning typically involves applying a thin layer of cooking oil to the pan and baking it in the oven at a high temperature. This process helps to create a protective layer that improves the pan's non-stick properties and overall performance.

- Simple maintenance: With proper care, cast iron pans are easy to maintain. Regular cleaning, drying, and occasional re-seasoning can extend the lifespan of the pan significantly. While it's important to avoid harsh chemicals and excessive scrubbing, gentle cleaning with warm water and a soft sponge or nylon brush is generally sufficient to keep the pan in good condition.

- Resistance to food contamination: Cast iron pans are known for their natural non-stick properties when properly seasoned. Even if the seasoning breaks down, the pan can be easily re-seasoned, preventing food contamination. Additionally, the high temperatures used during cooking and re-seasoning ensure that germs and bacteria are eliminated.

In summary, cast iron pans are challenging to ruin completely due to their durability, heat retention, and ability to withstand high temperatures and moisture. With proper care, maintenance, and occasional re-seasoning, a cast iron pan can last for generations, becoming a cherished kitchen companion.

Perfectly Seasoned Thin Crust Pizza Pans

You may want to see also

Cast iron pans are terrible at heating evenly

Cast iron pans are beloved by many for their versatility and longevity. However, contrary to popular belief, cast iron is not great at heating evenly. In fact, its thermal conductivity—the measure of a material's ability to transfer heat from one part to another—is only around a third to a quarter that of a material like aluminium. This means that when a cast iron skillet is placed on a burner, clear hotspots form directly above the flames, while the rest of the pan remains relatively cool.

To compensate for this issue, it is recommended that cast iron pans are preheated for at least 10 minutes, with the pan being rotated occasionally. Alternatively, the pan can be heated in an oven for 20 to 30 minutes. This is important as cast iron has a high volumetric heat capacity, meaning that once it is hot, it stays hot. This is ideal for searing meat, but it also means that uneven heating can lead to stress breaks or warping.

Another advantage of cast iron is its high emissivity, or its ability to expel a lot of heat energy from its surface in the form of radiation. This means that when cooking, you are not just cooking the surface in contact with the metal, but also a good deal of food above it. This makes cast iron ideal for dishes like hash or pan-roasted chicken and vegetables.

Despite the issue of uneven heating, cast iron pans are still a great option for many dishes. To get the most out of a cast iron pan, it is important to be aware of its limitations and take steps to mitigate them, such as preheating and rotating the pan.

Covered Roasting: Best for Poultry?

You may want to see also

Frequently asked questions

No, but pinholes are a common defect found in cast iron products. They are usually the result of a chemical reaction during the manufacturing process.

Small pinholes in cast iron pans can affect the structural integrity of the pan and may collect food particles that are difficult to remove, creating a breeding ground for bacteria. However, the extreme heat of the pan will kill any germs, and the oil used for seasoning the pan should fill up the holes.

To prevent pinholes from forming, you can limit the risk of air bubbles during the manufacturing process by altering the feedstock to reduce hydrogen carriers and shortening flow paths to limit oxidation.

If the hole is caused by rust, a little surface rust can be remedied by re-seasoning the pan. If the hole is larger or the pan is cracked, it should be replaced as it is no longer safe to use.