When installing a shower, you may wonder whether you need to include a lath in your mud pan. The answer is not straightforward, as it depends on various factors, including the size of the shower, the type of floor, and the specific requirements of the project.

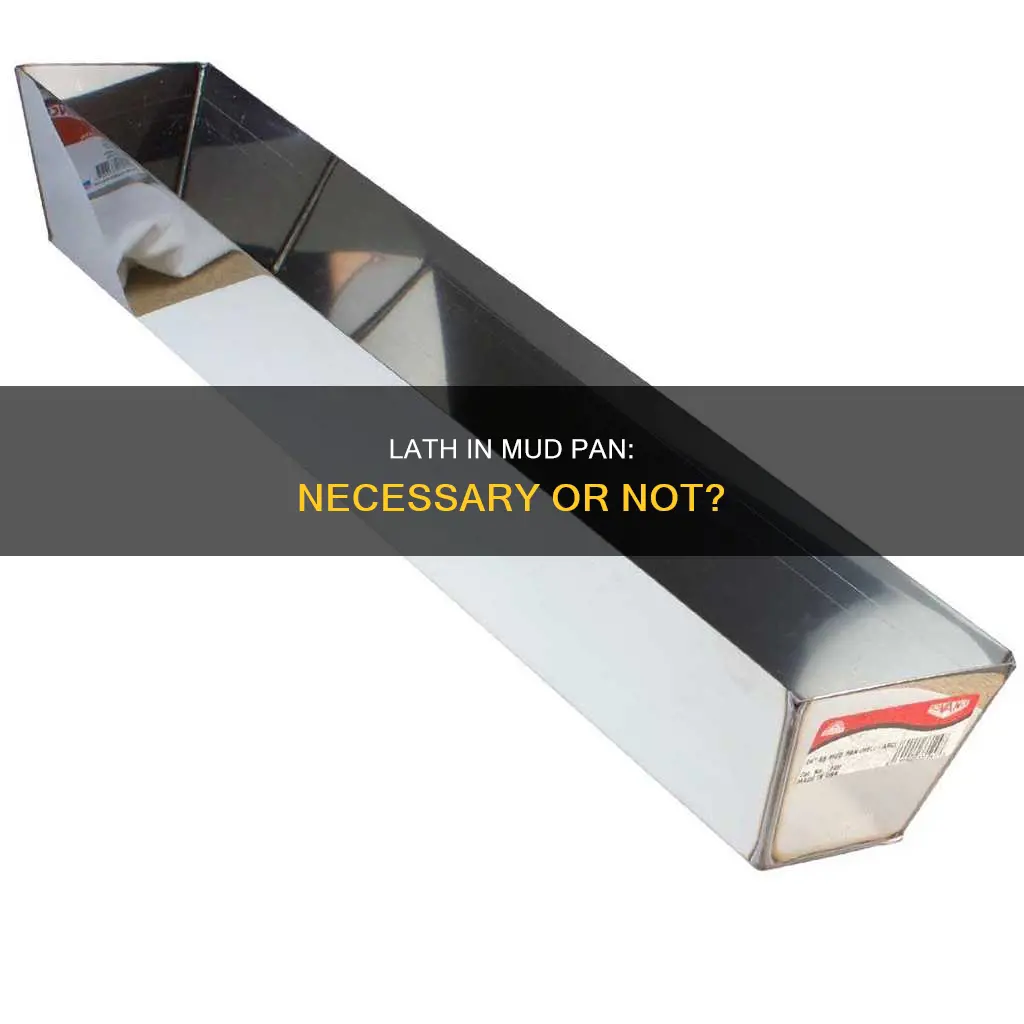

A lath is a flat, mesh-like material made from metal, similar in appearance to a chain-link fence. In a shower installation, it is used to anchor and strengthen the mortar bed, ensuring that it dries properly and forms an adequate bond between the layers of the shower base. While it is not technically necessary, including a lath can increase the durability and lifespan of the shower installation.

If you are installing a shower in an old house with unlevel carpentry, for example, a mud pan with a lath may be the best option to ensure a proper slope and drainage. On the other hand, if you are working on a remodel project and the floor is already level, a pre-sloped tray might be a more straightforward choice.

What You'll Learn

- Metal lath is not essential for a shower pan but can strengthen the bond between layers

- Metal lath is commonly used to anchor mortar in heavy-duty operations

- Metal lath is not part of the shower pan but appears underneath and on top of it

- Metal lath is not necessary when installing a pre-sloped tray

- A mud pan is more suitable for remodelling and custom-sized showers

Metal lath is not essential for a shower pan but can strengthen the bond between layers

A shower pan is the foundation of a stand-up shower, and it is crucial to get it right to avoid water damage. While metal lath is not essential for a shower pan, it can strengthen the bond between layers and enhance the overall durability of the shower.

Metal lath, also known as a metal mesh or netting, is installed over a cleavage membrane, which is typically a layer of building paper or roofing felt. The lath is secured to the subfloor using nails or staples. It serves as a reinforcing material and provides a mechanical bond with the subsequent layers of the shower pan.

One of the key benefits of using metal lath is that it helps to create a stronger, more rigid base for the shower pan. It acts as a framework that improves the structural integrity of the installation. This is especially beneficial when working with uneven or unstable subfloors. The lath helps to distribute weight more evenly and reduces the likelihood of cracks forming in the shower pan over time.

Additionally, metal lath can enhance the bond between the cleavage membrane and the subsequent layers of the shower pan. The lath's open structure allows the mud mix or mortar to pass through and interlock with it, creating a mechanical bond. This bond can be stronger and more durable than solely relying on the adhesion between layers.

It is important to note that while metal lath can strengthen the bond and improve the overall durability of the shower pan, it is not always necessary. Some installers choose to forgo metal lath, especially if they are confident in the stability of the subfloor and the adhesion of their chosen materials.

In summary, metal lath is not an essential component of a shower pan, but it can provide several benefits. It strengthens the bond between layers, improves the rigidity of the installation, and helps distribute weight more evenly. Ultimately, the decision to use metal lath depends on the specific project requirements, the condition of the subfloor, and the installer's preferences.

Pans: The Ultimate Kitchen Trio

You may want to see also

Metal lath is commonly used to anchor mortar in heavy-duty operations

Metal lath is a crucial component in construction projects, especially when it comes to anchoring mortar in heavy-duty operations. Its application provides stability and ensures the long-term durability of the structure. In this context, "heavy-duty operations" refer to construction projects that demand robust solutions, such as shower installations, floor repairs, or even exterior wall finishes.

One of the primary functions of metal lath is to serve as a reinforcing material for mortar applications. In construction, mortar is often used for bonding and creating solid surfaces. Metal lath is installed to provide a secure base for the mortar to adhere to, enhancing its strength and preventing cracks or failures. This is particularly important in areas that experience significant stress or weight-bearing loads, such as shower floors or exterior walls.

The process of installing metal lath typically involves several steps. Firstly, a moisture barrier is applied to the surface to create a waterproof area. This step is crucial to prevent wood decay and ensure the longevity of the structure. Next, the metal lath is unrolled and attached to the surface, usually with nails or staples, creating a tight and secure base. The lath is overlapped at the seams to ensure complete coverage and prevent any seepage of moisture.

After the metal lath is securely in place, a layer of mortar is applied on top. This layer of mortar bonds with the lath, creating a strong and unified surface. The mortar is then scraped to create scratches, which increase future adhesion for subsequent layers. This process results in a sturdy and durable surface that can withstand heavy-duty operations.

In the context of a mud pan installation, such as for a shower floor, metal lath plays a vital role in anchoring the mortar and ensuring its long-term stability. The lath provides a secure base for the mortar to adhere to, preventing it from cracking or failing under the weight and constant use. Additionally, the lath helps establish a proper slope for drainage, ensuring that water flows towards the drain instead of pooling on the shower floor.

Special Pans for Flat Burner Stovetops?

You may want to see also

Metal lath is not part of the shower pan but appears underneath and on top of it

A shower pan is a waterproof layer that sits between the shower base and the subfloor. It is sloped to ensure water flows toward the drain. Metal lath is not part of the shower pan but appears underneath and on top of it.

Metal lath is a base for plaster application, usually made from expanded steel. It is attached to the stud plane with staples, nails, or wafer-head lath screws. The plaster is then applied on top, keying around the metal to create a secure bond and a flat, smooth finish.

In the context of a shower pan, metal lath is used underneath to provide a base for the pan's surface material, such as tile or stone. It is attached to the underlying structure and helps to ensure the surface material adheres securely and evenly. On top of the shower pan, metal lath can be used to provide a base for an additional layer of plaster or other surface material, creating a smooth and durable finish.

While metal lath is not essential for a shower pan, it can enhance the installation process and the overall durability of the pan. It is particularly useful when working with uneven surfaces, as it helps to create a level base for the pan. Additionally, the openings in the lath allow for better adhesion and can help prevent leaks.

When using metal lath with a shower pan, it is important to ensure that it does not come into direct contact with any liner or moisture barrier. Proper installation is crucial to avoid leaks and potential flooding.

Roasting Pan for Ham: Necessary?

You may want to see also

Metal lath is not necessary when installing a pre-sloped tray

When installing a pre-sloped shower tray, metal lath is not always necessary. While some installers choose to include it in their process (e.g., in a traditional mud bed installation), others omit it with no issues. Here are several reasons why metal lath is not necessary when installing a pre-sloped tray:

- Waterproofing: The primary purpose of a pre-sloped tray is to ensure proper drainage and direct water towards the drain. This eliminates the need for a metal lath, which is typically used to create a slope for drainage. By using a pre-sloped tray, you achieve the necessary slope without the need for additional materials.

- Simplified Installation: Pre-sloped trays are designed for quick and easy installation. They come ready to tile and eliminate the need for traditional mud bed setups. This simplifies the process and reduces the time and labour required.

- Durability: Pre-sloped trays, such as those made from moulded extruded polystyrene (EPS), offer high durability and strength. EPS trays provide greater support for tile coverings and are lightweight yet resilient. This makes them easier to transport and handle during installation.

- Code Compliance: The use of a pre-sloped tray helps meet plumbing code requirements. The sub-incline, or pre-slope, is crucial to ensuring proper drainage. By installing the tray at the correct height and following manufacturer instructions, you can achieve code-compliant drainage without the need for metal lath.

- Reduced Weight: Pre-sloped trays offer the benefit of reduced weight compared to traditional mortar bed installations. This is especially advantageous in certain construction scenarios and can help simplify the overall installation process.

- Time Savings: By eliminating the need for a metal lath and traditional mud bed installation, pre-sloped trays significantly reduce installation time. In some cases, a complete shower setup can be finished in just one day, including flood testing, which is a significant advantage over traditional methods.

In summary, metal lath is not necessary when installing a pre-sloped tray. Pre-sloped trays offer a simplified, code-compliant, and durable solution for shower installations, providing proper drainage and reducing the time and effort required for the project.

Gold Panning: Permits Needed?

You may want to see also

A mud pan is more suitable for remodelling and custom-sized showers

Mud pans are built in two stages, with each stage using the same "dry pack" mixing method. The first layer of the shower pan is underneath the waterproofing membrane, which is often overlooked but establishes a drainage path for water if the top layers of the shower pan are compromised. The second layer, called the pan, is a durable chlorinated polyethylene (CPE) membrane. When installed, this vinyl liner turns up at the edges to create a waterproof membrane in the shape of a shallow pan.

Mud pans are a good option for remodelling because they can be customised to fit the space. For example, if the floor is uneven, it doesn't make sense to do a two-step process to level and then install a pre-sloped tray. A mud pan can be adjusted to fit the space. Similarly, if you have a specific or custom-sized shower, a pre-sloped tray might not be an option, and a mud pan will need to be used.

Mud pans are also a good option if you want to add hydronic heating to your shower, as the pipes can be installed underneath the tile floor.

However, mud pans are more time-consuming and require more skill to install than pre-sloped trays. They also carry a risk of leaking if they are not installed correctly.

Lodge Pans: Seasoning Secrets

You may want to see also

Frequently asked questions

Technically, you don't need metal lath in your mud pan. However, it helps strengthen the bond between the layers of your shower base, increasing its durability and lifespan.

The shower pan is the middle layer in a shower base. It protects your bathroom floor from any water that leaks through the shower floor or around the drain.

The pre-pan is the layer below the shower pan. It sits between the bathroom floor and the shower pan to anchor it.

Lath consists of a flat, mesh-like material made from metal, similar in appearance to a chain-link fence.

Lath helps to anchor mortar, which is a cement-like adhesive used to bind the layers of a shower base to one another.