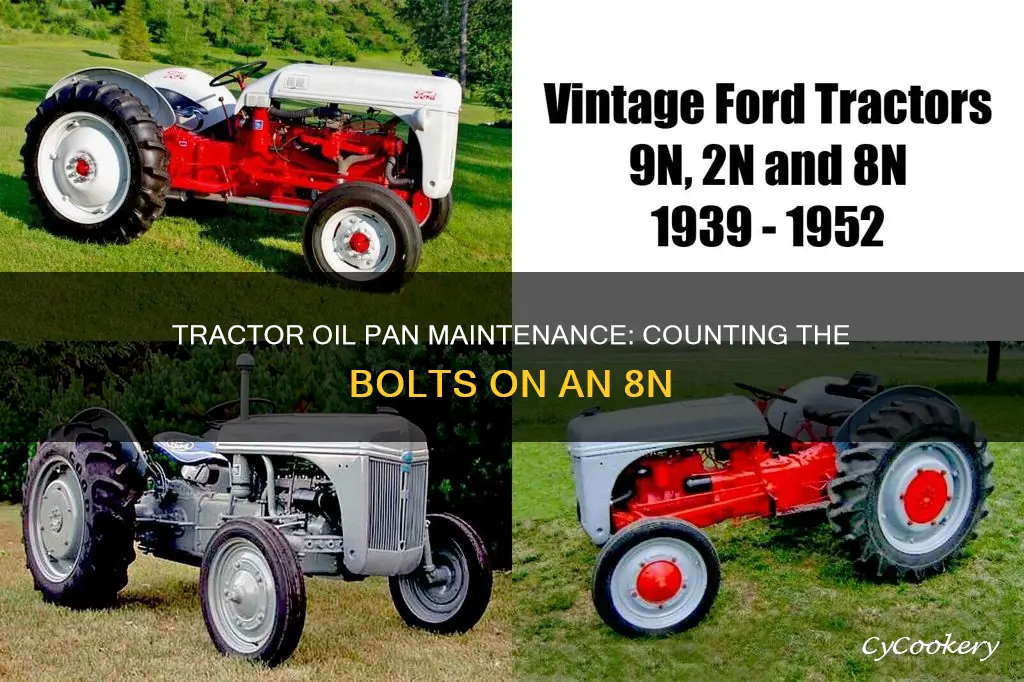

The oil pan on an 8N tractor is attached to the main frame, so removing it is a little complicated. The process involves several steps, including draining the oil, removing the oil pan mounting bolts, and prying the pan away from the engine. There are a number of bolts that need to be removed to detach the oil pan, and the exact number depends on the model of the tractor and the year it was made. In addition to the bolts around the pan flange, there are also two bolts that thread up from the bottom through the front cover. It is important to be careful during the removal process to avoid damaging the oil pan or the engine.

What You'll Learn

Removing the oil pan on an 8N tractor

Step 1: Prepare the Tractor

Before beginning the removal process, it is important to prepare the tractor. Drain the oil and antifreeze, and ensure the tractor is securely propped up on blocks or jack stands. You will also need to remove the hood, radiator, and front wheels to access the necessary components.

Step 2: Loosen the Gasket

The oil pan is typically sealed with a gasket, and breaking this seal is often the most challenging part of the removal process. Use a putty knife or a similar tool to carefully scrape and loosen the gasket. This may require a significant amount of force and a considerable number of strokes. Be careful not to damage the engine or oil pan during this process.

Step 3: Support the Oil Pan

The oil pan on an 8N tractor is part of the frame and is quite heavy. To prevent it from falling and causing damage or injury, it is crucial to support it adequately. Use a floor jack or a transmission jack to hold the oil pan in place as you work. Additionally, consider installing bolts on the corners of the oil pan and screwing them into the engine to provide extra support and control during the removal process.

Step 4: Remove the Front Axle and Pulley

The front axle and pulley may interfere with the removal of the oil pan. To address this, remove the bolts attaching the front axle housing to the oil pan, and carefully pull the front axle away from the tractor. You may also need to remove the front pulley by loosening the ratchet or nut holding it in place. Be cautious, as the crankshaft may want to turn during this process.

Step 5: Unbolt the Oil Pan

The oil pan is attached to the engine and transmission with multiple bolts. Remove all the bolts, including the ones that may be hidden under grime or located in less obvious places. Take your time and ensure that all bolts are removed before attempting to lower the oil pan.

Step 6: Lower the Oil Pan

Once all the bolts are removed, carefully lower the oil pan using the jack. Ensure that it drops straight down to avoid damaging the oil pickup tube, which is fragile. Have an extra set of hands ready to help guide and support the oil pan during this step.

Step 7: Clean and Prepare for Reinstallation

With the oil pan removed, take the opportunity to clean the mating surfaces and prepare for reinstallation. If you plan to reinstall a new oil pan, follow the manufacturer's instructions and ensure that all necessary parts and gaskets are ready.

Hot Pot Servings: The 6-Quart Surprise

You may want to see also

How to remove the oil pan without damaging the tractor

To remove the oil pan from an 8N tractor without damaging the tractor, you'll need to follow a careful step-by-step process. Here's a detailed guide to help you through the process:

Step 1: Prepare the Tractor

- Drain the oil and antifreeze from the tractor.

- Place the tractor on blocks or jack stands to ensure stability and access to the oil pan.

- Remove the hood, radiator, and front wheels for better access (optional but recommended).

Step 2: Loosen and Remove Bolts

- Loosen and remove the bolts connecting the oil pan to the tractor. This includes bolts at the front axle, bell housing, and side pan. Be sure to remove any hidden bolts at the front, under grime, and in the timing cover.

- Take your time with this step, as there are a lot of bolts to remove, and you don't want to miss any. The oil pan is heavy, so having it securely supported will make this step easier.

Step 3: Support the Engine and Transmission

- Use a floor jack or transmission jack to support the weight of the engine and transmission.

- Ensure that the jack is sturdy and stable to prevent the engine and transmission from falling and causing damage or injury.

Step 4: Deal with the Front Axle

- You can choose to remove the front axle or swing it out of the way. Removing it will give you more room to work, but swinging it aside is also an option.

- If removing the front axle, disconnect the steering and tie-rod ends, and move the axle and radiator forward.

- If swinging the front axle aside, drive the front radius-rod bolts/pins upward and out of the axle, or remove the foot-pegs and secure the radius rods to the steering rods.

Step 5: Remove the Oil Pan

- With all the bolts removed and the engine/transmission supported, carefully lower the oil pan using the jack.

- Be cautious of the oil pickup tube, ensuring that it doesn't get damaged during the removal process.

- The oil pan is heavy, so have an extra pair of hands or use a jack to lower it slowly and safely.

Step 6: Clean and Prepare for Reinstallation

Once the oil pan is removed, clean the mating surfaces and prepare for reinstallation, following the manufacturer's guidelines.

Remember to work slowly and carefully throughout the process. It's crucial to ensure that the oil pan is removed without causing any damage to the tractor or injuring yourself. Always refer to the tractor's service manual for specific instructions related to your model.

Removing Stubborn Bean Stains from Pans: A Step-by-Step Guide

You may want to see also

Steps to replace an oil pan gasket on an 8N tractor

Step 1: Prepare the tractor

- Park the tractor on a level surface and apply the parking brake.

- Block the back wheels to prevent any accidental movement.

- Place a catch pan or drain pan under the tractor to catch any spilled oil.

- Remove the oil plug using a wrench or ratchet and socket, and allow the oil to drain completely.

- Reinstall and seal the drain plug.

Step 2: Access the oil pan

- Inspect the area around the oil pan to determine if any parts need to be removed for better access.

- If necessary, unhook one or two motor mounts and use a floor jack to slightly raise the engine.

- Remove any cross members or the motor mount using a ratchet and socket to create more space to work with.

Step 3: Remove the oil pan

- Locate and remove the mounting bolts for the oil pan using a ratchet, socket, and long ratchet extension if needed.

- Be sure to remove all bolts, including any that may be hidden or difficult to see.

- Gently tap one side of the oil pan with a rubber mallet to loosen it from the engine.

- If needed, use a pry bar to slowly pry the oil pan away from the engine.

Step 4: Clean and prepare the surfaces

- Remove any residue, silicone, or old gasket material from the mounting surfaces of the engine block and oil pan using a gasket scraper.

- Be careful not to damage the mounting surfaces during this process.

- Clean the sealing surfaces thoroughly using a solvent to ensure they are free of any debris or residue.

- Inspect the oil pan for any damage, fractures, or cracks before proceeding.

Step 5: Install the new gasket

- Refer to the tractor's manual to identify the compatible oil pan gasket replacement for your specific model.

- Obtain the appropriate oil pan gasket replacement, ensuring it is suitable for the metals it will be sealing.

- Install the new gasket by following the instructions provided with the replacement.

Step 6: Reassemble and test

- Apply a thread sealer to the oil pan bolts, if specified by the manufacturer.

- Attach the oil pan bolts and torque them to the specified level in a spiral pattern, starting from the center.

- Reattach any accessory brackets that were removed during the process.

- Refill the oil pan with oil.

- Start the engine and inspect for any leaks.

Note: It is recommended to refer to a service manual for specific instructions and bolt locations, as well as to identify any vehicle-specific procedures that may be required.

Protecting Your Investment: Safeguarding Granite Countertops from Hot Pots and Pans

You may want to see also

The function of an oil pan and why it's important

The oil pan, attached to the bottom of the engine with bolts, is an integral part of a vehicle's lubrication system. Its primary function is to store the engine oil and provide a continuous supply to the engine's moving parts, such as the crankshaft, connecting rods, and camshaft. By ensuring proper lubrication, the oil pan prevents damage to the engine and maintains its smooth operation.

The oil pan collects and holds a sufficient amount of oil, which is then drawn by the oil pump and pressurised to circulate throughout the engine. This process involves forcing oil from the pan through a filter to remove dirt and debris before it reaches the engine. The oil pan also contains an oil pickup tube or screen that prevents debris, such as dirt and metal particles, from entering the oil pump and causing potential engine damage.

The design of the oil pan varies depending on the engine configuration and vehicle type. Most oil pans have a flat or slightly curved bottom, with internal features to control oil movement and prevent oil starvation during high-performance driving. Oil pans are typically made from steel, aluminium, or composite materials, with steel pans being more common in heavy-duty applications due to their durability, and aluminium pans used in lighter vehicles for weight reduction.

Maintaining the oil pan is crucial to ensure optimal engine performance and prevent engine damage. Regular oil changes, as per the manufacturer's recommendations, are essential to keeping the oil clean and maintaining the proper oil level. In addition, it is important to regularly inspect the oil pan for leaks, clean it to remove any accumulated debris, and check for any damage, such as dents or cracks.

A well-maintained oil pan ensures that the engine receives the necessary lubrication to function efficiently and prolongs the lifespan of the vehicle.

Papa Murphy's Pan Pizza: Baking Guide

You may want to see also

How to fill the engine back up with oil after an oil change

I could not find specific information about the number of bolts on an 8N tractor oil pan. However, I can provide detailed information on how to fill the engine back up with oil after an oil change.

How to Fill the Engine with Oil After an Oil Change:

Step 1: Determine the Correct Oil Type and Amount

Check your vehicle's owner's manual to find the recommended oil type and amount. The viscosity and quality level of the oil are important factors to consider. You can also check the oil cap or do a quick online search to cross-reference.

Step 2: Prepare the Vehicle

Use a jack to lift the car and give yourself room to work underneath. Remove any undertrays or covers that may be blocking access to the oil pan and oil filter. Examine the area for any oil leaks, and if found, consider having your vehicle inspected by a mechanic.

Step 3: Drain the Old Oil

Place an oil receptacle, such as a bucket or oil drain pan, underneath the drain plug. Loosen and remove the drain plug, allowing the oil to drain completely. Be careful not to let the drain plug fall into the receptacle.

Step 4: Remove the Old Oil Filter

Locate the oil filter, which is a softball-sized cylindrical component. Use your hand or an oil filter wrench to loosen it and allow the oil to drain. Remove the old oil filter, ensuring that the old oil filter gasket is not left behind, as this can cause leaks.

Step 5: Reinstall the Drain Plug and New Oil Filter

Replace the drain plug, tightening it snugly but not too tightly to avoid damaging the oil pan. Put a light coating of oil on the rubber gasket of the new oil filter, then install it, tightening it until it is snug.

Step 6: Fill the Engine with Oil

Reinstall the undertray and lower the vehicle back to the ground. Open the hood and locate the oil filler cap, typically marked with an oil can symbol. Using a funnel, fill the engine with the manufacturer's indicated volume of oil.

Step 7: Check the Oil Level and Leaks

Start the vehicle and run it for about 10 seconds to allow the oil to circulate. Use the dipstick to verify that the oil level is at the proper mark. Finally, check for any leaks under the vehicle and around the oil filter.

Tips and Considerations:

- Always use the oil type and amount recommended by the vehicle manufacturer.

- Be sure to wipe down any oil-covered surfaces before reinstalling the drain plug and oil filter.

- Do not over-tighten the drain plug or oil filter, as this can cause damage.

- It is important to check your oil level regularly and top it up when necessary. However, topping up the oil is not a substitute for a full oil change, which should be done according to the manufacturer's recommended schedule.

- When checking the oil level, ensure that the vehicle is on a level surface and that the engine has been turned off for at least 5 minutes to get an accurate reading.

- Adding oil to a hot or running engine is not recommended, as it can cause smoking or even a fire if oil is spilled.

By following these steps and considerations, you can safely and effectively fill the engine with oil after an oil change.

Removing Bath Bombs from a Muffin Pan: Easy Tricks

You may want to see also

Frequently asked questions

There doesn't seem to be a definitive answer to this question, but based on the available information, it seems that there are at least four bolts on the corners of the oil pan, and potentially several more around the pan flange.

Removing the oil pan on an 8N tractor can be a bit complicated as it is attached to the main frame. The process involves draining the oil, removing any necessary parts, and then taking out the mounting bolts for the oil pan. A rubber mallet or pry bar may also be needed to gently separate the engine and pan.

Common causes of oil leaks include deteriorated engine gaskets, oil pan leaks, and incorrect or worn seals. If you notice oil on the ground under your tractor or a sudden drop in oil level, these could be indicators of a leak.

If your 8N tractor oil pan is cracked, it is recommended to replace it. However, some people have successfully repaired cracks by drilling, welding, or brazing the affected area.

The recommended oil for an 8N tractor engine oil change is a standard engine oil that meets the API service classification of SF, SG, SH, SJ, or higher. You can refer to your tractor's user manual for specific recommendations and instructions.