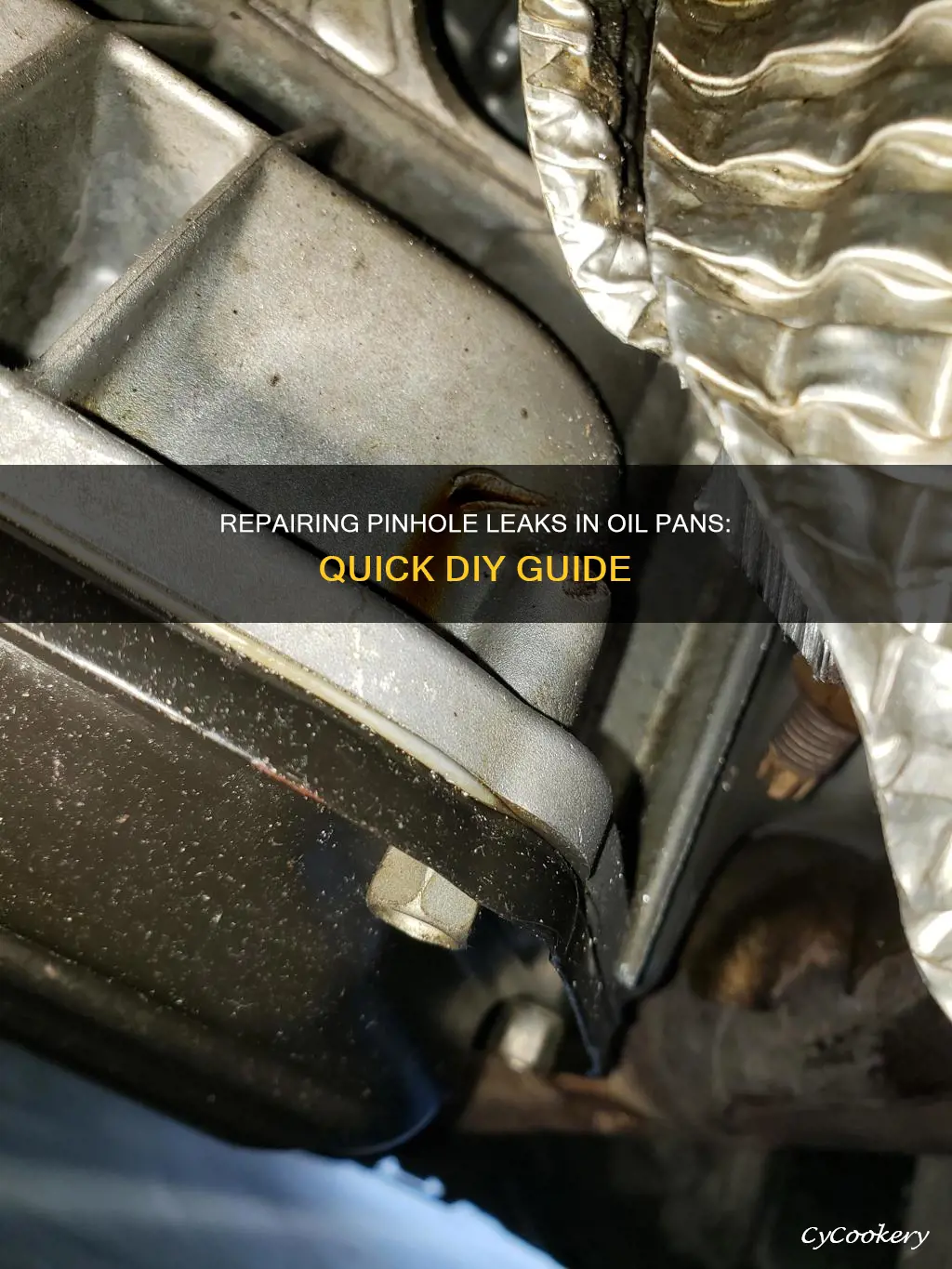

A pinhole leak in an oil pan can be fixed by using a two-part epoxy called JB Weld. The process involves draining the oil, cleaning the area with brake cleaner, and applying the JB Weld. It is important to ensure that the area is thoroughly cleaned and dried before applying the epoxy. The epoxy should then be allowed to cure overnight before refilling the oil. While this is a temporary fix, it can last for several years. For a more permanent solution, it is recommended to weld the hole shut or replace the oil pan entirely.

| Characteristics | Values |

|---|---|

| Clean the area around the pinhole | Use brake cleaner, alcohol, sandpaper, wire wheel, propane torch |

| Seal the pinhole | Use JB Weld, epoxy, sheet metal screw, RTV, solder, Seal All, or oil pan sealer |

| Painting | Spray with satin black and WD40 or similar |

What You'll Learn

Clean the area with brake cleaner

To fix a pinhole leak in your oil pan, you'll need to clean the area with brake cleaner. This is an important step to ensure that the repair is successful and long-lasting. Here's a step-by-step guide on how to do it:

First, make sure you have the right tools and materials. You'll need brake cleaner, which usually comes in an aerosol spray can. It's also important to have protective gear, including gloves and eye protection, as brake cleaner contains harmful chemicals. Work in a well-ventilated area to avoid inhaling the fumes.

Next, locate the pinhole leak in your oil pan. Once you've found it, use a cloth or rag to clean the area around the leak, removing any oil, grease, or dirt. This will ensure that the surface is free from contaminants that may interfere with the repair process.

Now, you can apply the brake cleaner. Shake the can well and spray it onto the affected area. Brake cleaner is designed to remove oil, grease, and debris, so it will effectively clean the pinhole leak and the surrounding area. Follow the instructions on the product and spray from the recommended distance, usually about a foot to 2 feet away.

After applying the brake cleaner, let it sit for a while. This will give it time to break down any remaining contaminants and allow them to wash away. You may need to apply a second coat for a more thorough cleaning.

Finally, wipe the area with a clean cloth to remove any remaining residue. Ensure that the surface is completely dry before proceeding with the next steps of the repair, such as applying epoxy or welding.

By following these steps and cleaning the area with brake cleaner, you'll create an optimal surface for the repair, ensuring a strong and durable fix for your pinhole leak in the oil pan.

Dropping Oil Pan on a 2000 Saab 9-3: Step-by-Step Guide

You may want to see also

Use a two-part epoxy like JB Weld

If you have a pinhole leak in your oil pan, you can use a two-part epoxy like JB Weld to fix it. This method is tried and tested by many car owners. Here is a step-by-step guide on how to do it:

Step 1: Drain the Oil and Clean the Area

Remove the oil from the pan and clean the area around the pinhole leak. Use a degreaser like brake cleaner to ensure that the area is free of any oil residue. Let it dry completely.

Step 2: Sand and Clean the Area

Use sandpaper, preferably with a heavy grit like 60-grit, to scuff the area around the pinhole. This will create a rough surface for the epoxy to adhere to. After sanding, clean the area again with brake cleaner or another degreaser.

Step 3: Use a Propane Torch (Optional)

Some people suggest using a propane torch to lightly heat the area. This helps burn off any remaining contaminants on the surface of the metal. However, be extremely cautious when using a torch, and do not use it in combination with chlorinated brake cleaner, as this can create a dangerous situation.

Step 4: Apply JB Weld

Make sure you are using the long cure variety of JB Weld, as it will have more time to set properly. Follow the instructions on the package to mix the two parts of the epoxy. Apply a generous amount of JB Weld to the pinhole and the surrounding area. You can also use a small self-tapping screw in the pinhole before applying the epoxy for added strength.

Step 5: Create a Vacuum (Optional)

For an even stronger repair, you can create a vacuum to draw the JB Weld into the pinhole. To do this, undo the oil filler and hook up a shop vac to the oil filler opening. This will create a vacuum that pulls the epoxy into the repair.

Step 6: Let It Cure

Allow the JB Weld to cure for the maximum recommended time in optimal conditions. Do not do this in extremely hot or cold temperatures, and avoid doing it when there are too many contaminants in the air, such as pollen or dust.

After the JB Weld has cured, you can refill the oil and your oil pan should be good as new! This method is a cost-effective and relatively easy way to repair a pinhole leak in your oil pan without having to replace the entire pan.

Greasing Nonstick Pans: Necessary?

You may want to see also

Apply a small screw with a rubber gasket

To fix a pinhole leak in an oil pan, you can apply a small screw with a rubber gasket. This is a more permanent solution compared to using an epoxy or sealant.

First, drain the oil and clean the area with a degreaser or engine cleaner. You want to make sure that the area is free of any dirt, oil, or debris before proceeding.

Next, you will need to drill a small hole at the location of the pinhole leak. The hole should be slightly smaller than the width of the screw threads. This will allow the screw to create a tight seal as it is threaded into the oil pan.

After drilling the hole, insert the screw with the rubber gasket. Make sure the gasket is properly seated and aligned with the hole. Tighten the screw securely, but be careful not to over-tighten as this may strip the threads or damage the oil pan.

Finally, refill the engine with oil and check for any remaining leaks. If the screw and gasket are properly installed, the leak should be sealed, and you can enjoy your leak-free oil pan!

Pizza Pan Essentials: What You Need to Know

You may want to see also

Use a propane torch to burn off contaminants

To fix a pinhole leak in your oil pan, you can use a propane torch to burn off contaminants. This is a crucial step in the repair process, as it ensures that the surface of the metal is clean and free of any impurities that could compromise the integrity of the repair.

- Clean the area around the pinhole leak: Before using the propane torch, it is essential to clean the oil pan thoroughly. Use a degreaser or brake cleaner to remove any oil, grease, or debris from the surface. Ensure that you follow the instructions on the product and allow adequate time for the cleaned area to dry.

- Prepare the propane torch: Propane torches are widely available and are commonly used in various industries, including metalworking. Ensure you have a suitable propane torch for the task, along with a full propane cylinder. Propane is a popular fuel choice due to its low price, ease of storage, and availability.

- Safety precautions: Propane torches can generate extremely high temperatures, so it is crucial to take the necessary safety precautions. Wear appropriate protective gear, including heat-resistant gloves, eye protection, and a respirator. Ensure adequate ventilation in the workspace, and have a fire extinguisher nearby in case of emergencies.

- Ignite the propane torch: Follow the manufacturer's instructions to safely ignite the propane torch. Adjust the flame to a suitable size and temperature for the task. If your torch has a pressure regulator, ensure it is set correctly.

- Apply heat to the pinhole area: Direct the inner flame of the propane torch towards the pinhole leak. Hold the flame approximately half an inch away from the surface. Use slow and controlled movements to avoid overheating any particular area.

- Burn off contaminants: Maintain the application of heat with the propane torch until you see any contaminants or impurities on the metal surface burning off. This process ensures that the metal is clean and ready for the next steps of the repair.

- Allow the metal to cool: Once you have burned off the contaminants, remove the heat from the metal and allow it to cool down naturally. Do not apply water or any other cooling agent directly to the heated metal, as it could cause warping or damage.

Remember, working with a propane torch requires caution and adherence to safety guidelines. Always prioritize your safety and follow the instructions provided by the manufacturer of the propane torch.

Removing Melted Plastic from Non-Stick Pans: Quick Solutions

You may want to see also

Remove the oil pan and weld the hole shut

If you have a pinhole leak in your oil pan, one solution is to remove the oil pan and weld the hole shut. Here is a step-by-step guide on how to do this:

First, drain the oil from the pan. This is an important step to ensure that the area to be welded is clean and free of any oil residue. Once the oil is drained, remove the oil pan from the vehicle. This may involve raising the engine, so it is important to have a clear and safe work area.

Next, clean the oil pan thoroughly. Use a degreaser or brake cleaner to remove any remaining oil or grease from the pan, especially around the area of the pinhole leak. You may need to use a wire brush or sandpaper to scrub the area clean. It is crucial that the metal is clean and free of any contaminants before welding.

Once the oil pan is clean and dry, you can begin the welding process. If you are not experienced with welding, it is best to consult a professional welder or a repair shop to ensure a safe and effective repair. They will use appropriate welding techniques and materials to seal the hole shut.

After the welding is complete, allow the weld to cool and inspect the repair to ensure it is secure. Reinstall the oil pan, making sure to use a new gasket for a tight seal. Refill the oil and check for any leaks.

By following these steps, you can effectively repair a pinhole leak in your oil pan by removing it and welding the hole shut. This method provides a permanent solution compared to temporary fixes such as epoxy or putty. Always prioritize safety and consult experts if you are unsure about any part of the process.

Unsticking Stainless Steel Pans

You may want to see also

Frequently asked questions

The best way to fix a pinhole leak in an oil pan is to use JB Weld, a two-part epoxy that can withstand high temperatures. Drain the oil, clean the area with brake cleaner, and apply the JB Weld. Let it cure overnight, then refill it with oil.

If the leak is caused by rust, it will only get worse and the best option is to replace the pan. However, if there is no rust, you can try a temporary fix such as epoxy or a screw and RTV.

JB Weld is a popular and effective option for repairing oil pan leaks. It is a two-part epoxy that forms a strong bond and can withstand high temperatures. Make sure to clean the area thoroughly before applying.

Yes, other alternatives include using a sheet metal screw with RTV or welding the hole shut. However, welding may not be an option if you cannot remove the oil pan.