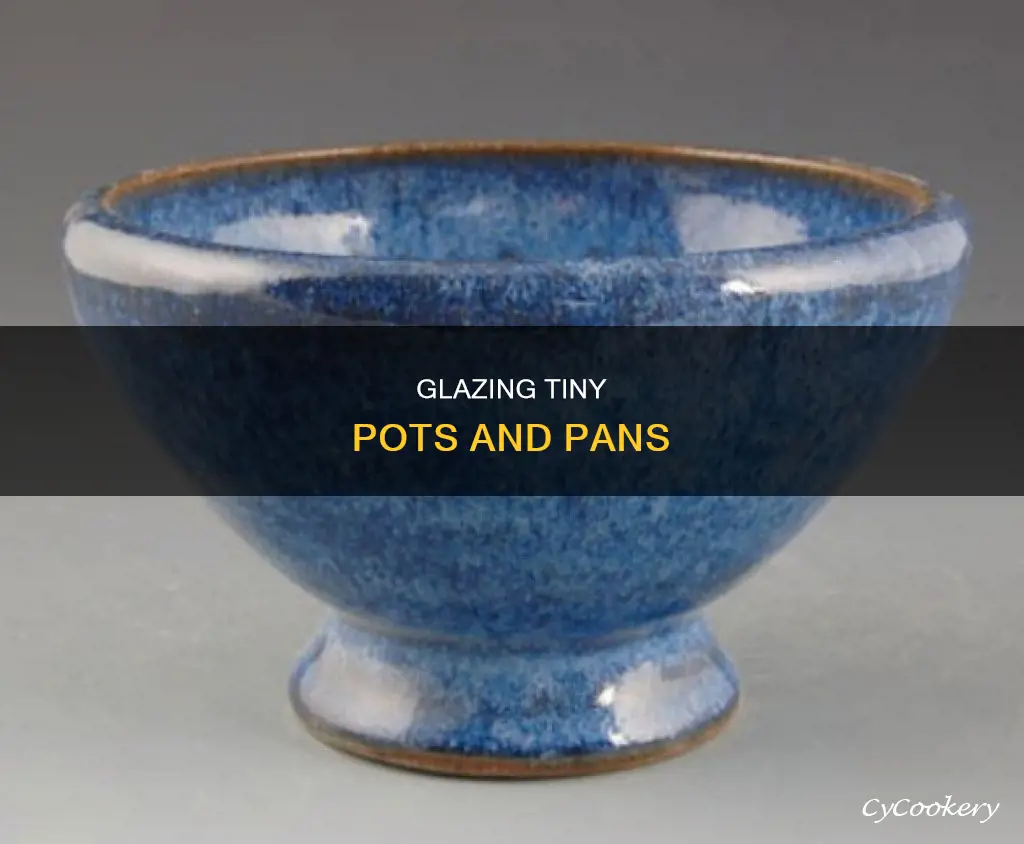

Glazing small pots and pans can be a fun and rewarding project, but it requires careful preparation and the right tools. Here's an introduction to help you get started on glazing very small pots and pans:

Before you begin glazing, it's important to have the right equipment and materials. This includes items such as brushes, sponges, and gloves to protect your hands. You will also need to choose the type of glaze you want to use, such as liquid or powder, and select the appropriate colours and consistencies. It's recommended to start with pre-mixed glazes if you're a beginner.

The first step in the glazing process is to prepare your pots and pans by removing any excess clay or uneven patches with sandpaper or a knife. It's important to work in a well-ventilated area and wear protective gear, such as gloves and a mask, to avoid inhaling clay dust. Once your pieces are smooth, clean them thoroughly to remove any dust or residue.

When you're ready to apply the glaze, there are several methods you can use. You can dip your pots and pans into a bucket of glaze, pour the glaze over them, or use brushes or sponges for more detailed work. It's important to allow each layer of glaze to dry completely before applying the next one. You can also create different effects by combining different colours and types of glazes.

Remember to always follow safety precautions when working with glazes and pottery tools. Some glazes contain harmful ingredients, so be sure to read the labels carefully. Additionally, make sure to work in a well-ventilated area to avoid inhaling glaze particles.

Finally, once you've applied the final layer of glaze, you'll need to fire your pots and pans in a kiln to set the glaze. You can either use a commercial kiln service or invest in your own kiln. Firing temperatures and times will depend on the type of glaze you've used, so be sure to follow the manufacturer's instructions.

| Characteristics | Values |

|---|---|

| Purpose | Decorate pottery, make it waterproof, food-safe, and attractive |

| Glaze types | Gloss or matte, low-fire, mid-fire, high-fire |

| Glaze application | Dipping, pouring, brushing, airbrushing, spraying |

| Glaze preparation | Mix glaze powder with water, stir thoroughly, sieve, adjust viscosity, let stand |

| Pottery preparation | Sand, clean, apply wax to base, let dry |

| Firing | In a kiln, at specific temperature for the glaze |

What You'll Learn

Choosing the right glaze

Type of Clay

It is important to choose a glaze that is compatible with the type of clay you are using. Different clays, such as earthenware, stoneware, and porcelain, have specific temperature ranges at which they should be fired. Using a glaze that is not suitable for your clay can result in issues such as crazing or shivering.

Application Method

The way you want to apply the glaze is another factor to consider. Glazes can be applied by dipping, brushing, or spraying. Dipping glazes are ready-made liquid glazes that are typically sold in larger quantities and are suitable for submersion. Brushing glazes, on the other hand, are thicker and come in smaller quantities, making them ideal for applying with a brush and experimenting with layering and combining glazes.

Glaze Form

Glazes come in two forms: powdered dry glaze and ready-mixed liquid glaze. Powdered glazes need to be mixed with water before use, while ready-mixed glazes can be used directly. Ready-mixed glazes offer convenience, but powdered glazes can be more cost-effective in the long run.

Firing Temperature

Consider the firing temperature of your kiln when choosing a glaze. Glazes are categorized as low-fire, mid-fire, or high-fire, and each type has distinct qualities. Low-fire glazes produce strong, bright colours, while mid and high-fire glazes tend to have more earthy tones. Additionally, the firing temperature affects the functionality of your pottery, with higher temperatures resulting in less porous and more watertight pieces.

Functionality

Decide whether you want your pottery to be purely decorative or functional. If you intend to use your pots and pans for food and beverages, ensure that the glaze is food-safe and will create a watertight seal. Earthenware glazes, for example, are suitable for this purpose.

Kiln Type

The type of kiln you are using can also impact your glaze choice. Electric and gas kilns produce different results due to the chemical processes of oxidation and reduction. Electric kilns tend to yield brighter colours, while gas kilns can create darker, more rustic glazes.

Safety

Always prioritise safety when choosing a glaze. Avoid glazes that contain lead, and opt for lead-free, food-safe options. Even if a glaze is labelled as lead-free, it is recommended to test your finished ware in a laboratory to ensure it is truly food-safe.

Crochet Pan Scrubbers: Cost Analysis

You may want to see also

Preparing the object and glazes

Before glazing your pottery, you must first ensure that it is clean and free of any dirt or oil. Use a damp sponge to wipe down the object and always wear disposable gloves when handling it. If there are any bumps or imperfections on the surface, sand them off using sandpaper and then wipe away the dust with a damp sponge.

The next step is to apply wax to the base of your object and any other areas where separate parts touch, such as the rim of a lid. This will prevent glaze from sticking to the kiln during the firing process. You can use a paintbrush to apply the wax, and there are various types available, including paraffin wax, "wax resist", and crayons.

If you are mixing your own glazes, it is important to follow the instructions and safety procedures carefully. Pre-mixed glazes are recommended for beginners due to the complexity and safety hazards involved in mixing your own. Always wear a respirator mask, safety goggles, and gloves when mixing your own glazes, and work in a well-ventilated area or outdoors. The process will require water, a long stirring spoon, a hydrometer, a drill mixer, a rubber spatula, two containers, a scale, and a fine mesh sieve.

Choosing and Preparing Glazes

There are many different types of glazes available, which vary in colour, texture, transparency, and opacity. You will also need to choose a glaze that is suitable for the type of clay you are using and the temperature your kiln can reach. Low-fire glazes are great for controlled designs and bright, predictable colours, while mid-fire glazes offer more variation and romantic visual effects. High-fire glazes produce the most durable ceramics but have a more limited colour range.

Once you have chosen your glaze, you will need to prepare it. If you are using a pre-mixed liquid glaze, pour it through a metal sieve to remove any lumps. If you are using a powdered glaze, mix it with water, following the manufacturer's instructions. Always add water slowly and stir vigorously with a whisk or a stirring rod attached to a power drill. You may also need to let the glaze sit for at least 24 hours before applying it.

Applying the Glaze

There are several methods for applying glaze to your pottery, including dipping, pouring, brushing, and spraying. Each method requires specific types of tools and equipment, so be sure to do your research before getting started. Remember to always apply wax to the bottom of your pottery before glazing and to wipe away any excess glaze that may cause it to stick to the kiln.

Drip Pan Style Guide

You may want to see also

Applying the glaze

There are several ways to apply glaze to your pottery, including dipping, pouring, brushing, airbrushing, and spraying.

Dipping

This is one of the fastest ways to glaze your pottery, and it ensures an even coat. Before dipping, make sure you've coated the bottom of your pot with wax resist. You should also stir the glaze before dipping your pot in it. The thinner the glaze, the longer you'll need to dip your pot.

Pouring

Glazes used for pouring are the same consistency as dipping glazes and are often used in conjunction with dipping. To glaze the interior, pour the glaze into your pot, leave it for three seconds, then pour it back into the glaze bucket. You can then flick off any excess glaze, wipe it with a sponge, or leave it for a decorative effect. You can also pour glaze over the outside of your pot to apply a thinner coat over a base layer of glaze.

Brushing

Commercial glazes are often thicker than dipping and pouring glazes and are usually applied with a brush. Make sure to read the instructions carefully, as they will tell you how many coats to use. Brushes come in various shapes and sizes and are meant to accomplish different tasks during the glazing process. Thick brushes are useful for covering large areas, and thinner ones are good for small touch-up jobs.

Airbrushing

Airbrushing involves spraying a thin mist of glaze onto the pottery and is a great way to apply an even coat. It's also good if you want to create a gradient between two glaze colours. However, airbrushing requires more equipment than other glazing methods, such as an airbrush gun and a spraying booth.

Spraying

Spraying glazes should always be done in a spray booth with adequate ventilation, and a respirator should be worn whenever spraying any ceramic materials, including glazes.

Best Grease for Salmon Pans

You may want to see also

Firing the glaze

Preparing for the Second Firing

Before you place your glazed piece in the kiln, there are a few things you should do:

- Ensure that the glaze is completely dry.

- Wipe off any excess glaze from the bottom of the pot and any spots where removable parts meet. This will prevent the glaze from sticking to the kiln or other pots.

- If you applied wax to these spots, you can simply wipe off any glaze that has gotten onto the dried wax.

- If you did not use wax, you can use an abrasive scrub pad to completely remove the excess glaze.

Now, you are ready to fire the glaze. Here's what you need to do:

- Place your glazed piece in the kiln.

- Slowly bring the kiln to the appropriate temperature for your glaze. This temperature will depend on the type of glaze you are using. Low-fire glazes are fired at 1845°F, mid-fire glazes at 2192°F, and high-fire glazes at 2305°F.

- Hold the kiln at this temperature for a specified amount of time, which will also depend on the type of glaze.

- Slowly cool the kiln back down.

- Once the kiln has cooled, usually after about 12 hours, you can open it and see your finished pot for the first time.

Tips for Firing the Glaze

- The firing process should be done slowly and gradually to prevent the piece from bursting.

- Many kilns have programmable cone settings to help prevent the piece from bursting.

- The final temperature may be decided through trial and error and is influenced by the type of clay and glaze you are using.

- Always follow the instructions for your specific glaze when firing. Firing at the wrong temperature can cause your piece to break.

- If you are using a glaze that requires a high temperature, you may need to use a kiln that can reach those temperatures, such as a brick kiln or a barrel kiln.

Remember to always practice safety when working with kilns and consult a professional if you need help.

Bug Bodies: Weighing the Parts

You may want to see also

Finishing touches

Removing Excess Glaze

Before you place your pottery in the kiln, make sure to wipe off any excess glaze from the bottom of the pot. This is important because the glaze contains glass-forming ingredients that melt when heated, and you don't want your pot to stick to the kiln shelf. You can also use wax resist to prevent glaze from sticking to the bottom of the pot.

Drying the Glaze

Once you've applied the glaze, you'll need to let it dry completely before firing your pottery. The drying time will depend on the thickness of the glaze and the humidity levels in your workspace. It's important to be patient during this step, as rushing it can lead to cracks or other issues with your glaze.

Firing the Glaze

After the glaze has dried, it's time to fire your pottery in the kiln. The firing temperature will depend on the type of glaze you're using, so be sure to follow the manufacturer's instructions. Remember to place your pottery in the kiln carefully, as it will be more fragile after glazing.

Multiple Layers of Glaze

You can add as many layers of glaze as you want to create unique designs and effects. Just be sure to allow each layer to dry completely before applying the next one. You can also experiment with different colours and types of glazes to create interesting visual effects.

Testing for Durability

If you plan to use your glazed pottery for food or drinks, it's important to test its durability. One method is to squeeze lemon juice onto the ceramic piece after it has cooled. If the acid changes the colour or texture of your piece, it may not be food-safe. You can also fill the pot with water to see if the liquid leaks through the ceramic pores.

Stainless Steel Pans: Nonstick or Not?

You may want to see also

Frequently asked questions

First, ensure your pots and pans are clean and free of dust. If you notice any bumps or imperfections, sand them off using sandpaper. You can then apply wax to the base and any removable parts to prevent glaze from sticking.

There are several techniques for applying glaze, including dipping, pouring, brushing, and spraying. For small items, dipping and pouring are effective methods to ensure an even coat of glaze. Brushing and spraying allow for more precision and are ideal for creating patterns or designs.

Allow the glaze to dry completely before firing your pots and pans in a kiln. The firing temperature will depend on the type of glaze you are using, so be sure to follow the manufacturer's instructions. You can also use a DIY kiln or alternative firing methods if you don't have access to a kiln.