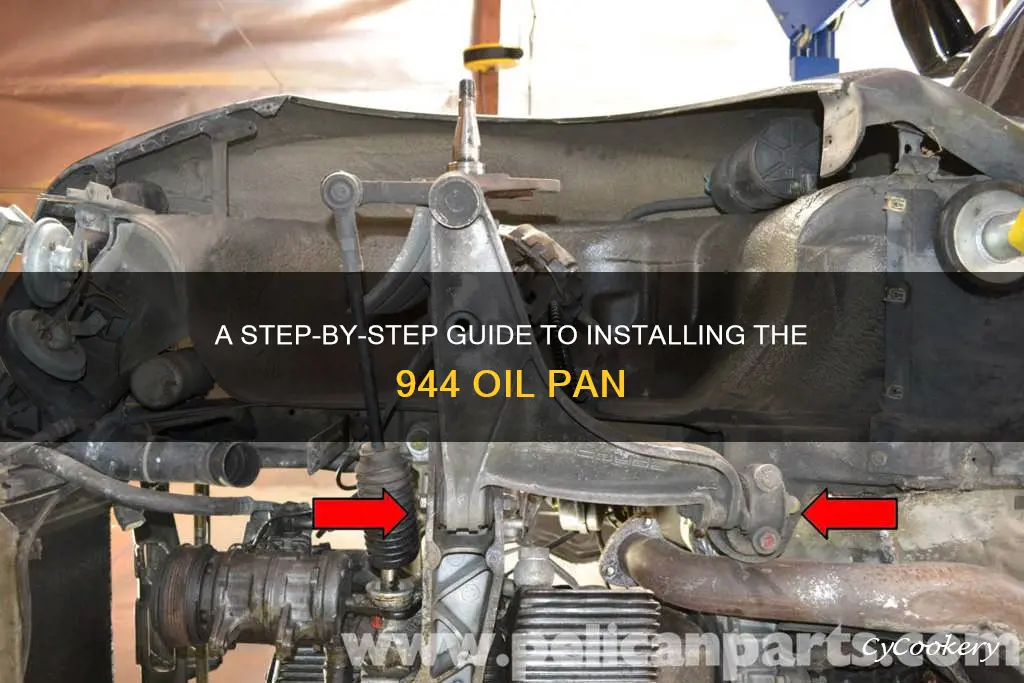

Installing an oil pan gasket on a Porsche 944 is a complex and time-consuming task. The process involves raising and supporting the vehicle, disconnecting the battery, and removing various components, such as the fuel rail, injectors, intake manifold, and turbo crossover pipe. It is essential to have a proper support system for the engine and safely dispose of used motor oil. The job typically takes 8 to 14 hours, depending on the vehicle model. While it is doable for a weekend mechanic, it may require the entire weekend to complete.

What You'll Learn

Disconnect the battery and safely raise the vehicle

Disconnecting the battery and safely raising your vehicle are crucial steps in installing a 944 oil pan. Here are some detailed instructions to guide you through the process:

Disconnecting the Battery:

Before you begin, ensure you have the necessary tools, such as a socket wrench or wrench kit, and protective gear, including gloves, an apron, and goggles. Working on your car battery carries a risk of electrical injury, so safety should be your top priority.

Step 1: Turn off the engine and remove the keys from the ignition. Never attempt to disconnect the battery while the engine is running.

Step 2: Locate the battery. In most vehicles, it is in the engine compartment, but it could also be in the trunk or under the rear seat. Refer to your vehicle's manual if you're unsure.

Step 3: Identify the battery terminals. The negative terminal is marked with a "-" symbol and usually has a black cable, while the positive terminal has a "+" symbol and often a red cable.

Step 4: Disconnect the negative terminal first. Use your wrench to loosen the nut or bolt securing the terminal, then carefully lift the cable off the battery post. Set it aside, ensuring it doesn't touch any metal surface.

Step 5: Repeat the process for the positive terminal. Again, ensure that the positive and negative terminals do not touch each other or any metal surface. You may want to isolate the positive cable end by wrapping it in a non-conductive material, like a towel.

Step 6: Loosen and remove the battery hold-down, which keeps the battery in place while driving. Locate the fasteners and loosen or remove them, then take out the battery hold-down.

Step 7: Remove the battery carefully, ensuring it remains level to prevent battery acid from spilling. Car batteries can be heavy, weighing around 30-50 pounds, so lift with your legs to avoid back injury. Place the battery on a dry, flat surface.

Safely Raising the Vehicle:

When it comes to raising your vehicle, safety is of utmost importance. Here are some steps to follow:

Step 1: Park your car on level ground and ensure it is in gear with the handbrake pulled. Chock the wheels to prevent the car from rolling while it's being lifted.

Step 2: Identify your car's jack points. These are typically located next to the wheels, between the wheelbase, and the rear of the car may be lifted from the differential.

Step 3: Use a jack to lift the car. A hydraulic jack is ideal, but if you don't have access to one, you can use jack stands or an air lifting bag. Always follow the manufacturer's instructions for your specific jack model.

Step 4: Place jack stands under the jacking points and adjust them to the appropriate height. Lock them into place securely.

Step 5: For added safety, it is recommended to have an assistant present while you work on the car, even if they don't actively participate in the task.

By following these steps, you can safely disconnect the battery and raise your vehicle, allowing you to access the underside of your car and proceed with the installation of the 944 oil pan.

Capturing Motion: Pressing the Shutter for Panning Effects

You may want to see also

Remove the drain plug and drain oil

To remove the drain plug and drain the oil, begin by placing a large catch pan or bucket beneath the drain plug on the lower right side of the engine. Use a 15mm socket or wrench to loosen and remove the drain plug. Be cautious as the flow of oil out of the pan will change as the oil level gets lower. It is important not to simply remove the plug and leave a bucket underneath, as this may result in a mess.

The torque specifications for the drain plug are 37 ft-lbs, but it is not uncommon for people to overtighten this plug. Ensure you have a firm grip on the socket or wrench and apply force in a counter-clockwise direction to loosen and remove the drain plug. With the drain plug removed, the oil will begin to drain from the pan. Allow sufficient time for the oil to drain completely before proceeding to the next step.

Once the oil has drained, it is important to properly dispose of the used motor oil. Most oil change shops will accept your used motor oil at no charge. Alternatively, you can store the used oil in a sealed container and contact your local waste management facility for information on how to properly dispose of it.

After draining the oil, the next step is to clean the drain plug and the area around it. Use a clean rag or brush to remove any oil residue or debris from the drain plug and the surrounding area. This step is important to prevent any dirt or debris from entering the oil pan when the drain plug is reinstalled.

Now, you can proceed to inspect the oil for any signs of debris or contamination. A small amount of metal sludge in the drained oil is normal, but be on the lookout for any large pieces or shavings that could indicate damage to the engine or bearings. If you notice any abnormal amount or type of debris, further inspection of the engine and related components may be necessary.

Black Pans: Scratches and Health Risks

You may want to see also

Remove the fuel rail, injectors, and intake manifold

To remove the fuel rail, injectors, and intake manifold, you will need to follow a detailed process that involves multiple steps. Here is a comprehensive guide to help you with the process:

Firstly, make sure you have the necessary tools and safety equipment. This includes an engine support bracket or hoist, floor jack, jack stands, wheel chocks, safety glasses, and a torque wrench. It is important to work safely and ensure the vehicle is securely supported. Disconnect the battery and place a large catch pan or bucket below the drain plug on the lower right side of the engine.

Next, use a 15mm socket or wrench to remove the drain plug. Be cautious as the flow of oil out of the pan will change as the level gets lower. Do not leave the bucket unattended.

Now, we move on to the fuel rail and injectors. For this step, refer to the article on fuel rail and injector removal for detailed instructions. This step is crucial and requires careful attention. Once the fuel rail and injectors are removed, proceed to the intake manifold. Again, for this step, you will need to refer to the article on intake manifold removal for specific instructions. It is important to follow the recommended procedures for a safe and effective removal process.

At this stage, you should have successfully removed the fuel rail, injectors, and intake manifold. However, there are still several steps to complete the oil pan installation process. Refer to the other steps mentioned in the article, such as removing the turbo crossover pipe, the turbo water pump, and various nuts and bolts, to gain access to the oil pan. Remember to follow the torque specifications and sequence provided in the article to ensure a proper seal and avoid over-tightening.

Oil Pan Drain Plug: A Small Mistake, Big Consequences

You may want to see also

Remove the turbo crossover pipe

To remove the turbo crossover pipe, follow these steps:

Firstly, you will need to drain the coolant to below the level of the pipe. It is important to ensure that the vehicle is cool to the touch before you begin. Follow the instructions for draining and bleeding your coolant. Now is also a good time to consider flushing your coolant system.

Next, remove the air box and air pipes. You can now see the crossover pipe, as well as the bracket for the air box. In this step, the intercooler to intake manifold pipe should still be in place.

Remove the fresh air to turbo supply side boot by detaching all the hoses attached to it with a flathead screwdriver. Then, loosen the clamp connecting it to the turbo and remove the boot.

With the boot removed, you can now see the supply side of the crossover pipe. Separate the large hose from the crossover pipe, which supplies coolant to the crossover pipe and the electrical coolant pump. Use a flathead screwdriver for this step. If you are replacing the hose, separate it from the coolant reservoir and the electrical coolant pump. Then, remove the clamp and the hose that connects to the head.

With everything disconnected, use a 10mm socket to remove the two bolts holding the crossover pipe to the frame rails.

Now, working on the right side of the motor, remove the hose that connects from the crossover pipe to the radiator. This is how the coolant flows from the reservoir to the radiator. Detach the clamp and hose to the radiator, as well as the hose that connects to the coolant pump housing.

Use a 10mm socket to remove the two bolts holding the right side of the crossover pipe to the frame rail. You can now manoeuvre the pipe out from the engine area.

With the pipe removed, you can see where the "y-hose" from the coolant reservoir connects to the crossover pipe and the electric pump, as well as where it exits the crossover pipe. You can also see where the hoses from the coolant pump to the head are attached.

Installation is the reverse of removal.

To Chill or Not to Chill: The Great Cheesecake Conundrum

You may want to see also

Remove the front control sway arm and control arms

To remove the front control sway arm and control arms, you will need to follow these steps:

Firstly, jack up the car and secure it on jack stands. Remove the front wheels and skid pans. This will expose the control arms and the sway bar.

Next, disconnect the front sway bar from the body and the control arm. You will need to remove the 13mm bolts and the 17mm bolt on top of the control arm. Now, the sway bar can be removed from the car.

Then, remove the nut and bolt that attach the spindle to the ball joint. This will allow you to separate the ball joint from the control arm.

Now, you can remove the control arm. Remove the bolts securing the control arm to the frame and, if necessary, pry it out with a pry bar. Make sure the axle shaft does not get overextended during this process.

Once the control arm is removed, you can replace it with a new one. Ensure you compare the new control arm with the old one to confirm they are the same design.

This process should be undertaken with care to avoid damage to surrounding components and to maintain proper alignment. It is also important to wear appropriate safety gear and use the correct tools for this task.

The Magic of Seasoning Cast Iron Pans: A Beginner's Guide

You may want to see also

Frequently asked questions

It is estimated that it takes 8-12 hours to replace the oil pan on a normally aspirated 944 and 12-14 hours for a turbocharged car.

You will need an engine support bracket or hoist, floor jack, jack stands, wheel chocks, safety glasses, torque wrench, large drain pan, and a series of extensions and a universal joint.

You will need an oil pan gasket, oil, new injector O-rings, white lithium grease, intake manifold gaskets, and a sealant such as Silastic RTV 730 or Permatex Ultra Grey.

First, safely raise and support the vehicle and disconnect the battery. Then, drain the oil from the pan. Next, remove the fuel rail, injectors, intake manifold, and turbo crossover pipe. Support the engine from above and remove the four cross-member-to-body bolts, oil pan retaining bolts, and the oil pan itself. Clean and inspect the oil pan, remove the old gasket, and install the new gasket. Finally, install the steering rack and cross-member assembly, torque the bolts, and reattach the hoses and control arms.

Yes, it is recommended to replace the rod bearings while installing a new oil pan. Additionally, ensure that the block and oil pan are completely dry when installing the new gasket and use an adhesive or sealant to secure the gasket and prevent leaks.