Removing and replacing floor pans in a car is a common task for car restorers and enthusiasts. Floor pans can become rusty and damaged over time, requiring repair or replacement. The process can range from simple patch repairs to address surface rust or pinholes to more extensive replacements of the entire floor pan with a one-piece panel. The method chosen depends on the severity of the damage, the skill and budget of the restorer, and the availability of parts for the specific car model. This topic will cover the different approaches to removing and replacing floor pans, including the tools and techniques required for a successful restoration.

What You'll Learn

Removing rust from car floor pans

Assess the Rust Damage

Before starting the removal process, it's important to evaluate the extent of rust damage on your car floor pans. Surface rust, characterised by minor corrosion, can often be addressed with a grinder and wire wheel to clean the old sheet metal. In such cases, you can then proceed with proper sealing to prevent further rust formation.

However, if the rust damage is more severe, with larger holes or extensive corrosion, a more comprehensive approach is required. This may involve patching up the affected areas or, in extreme cases, replacing the entire floor pan with a new one.

Prepare Your Workspace and Gather Tools

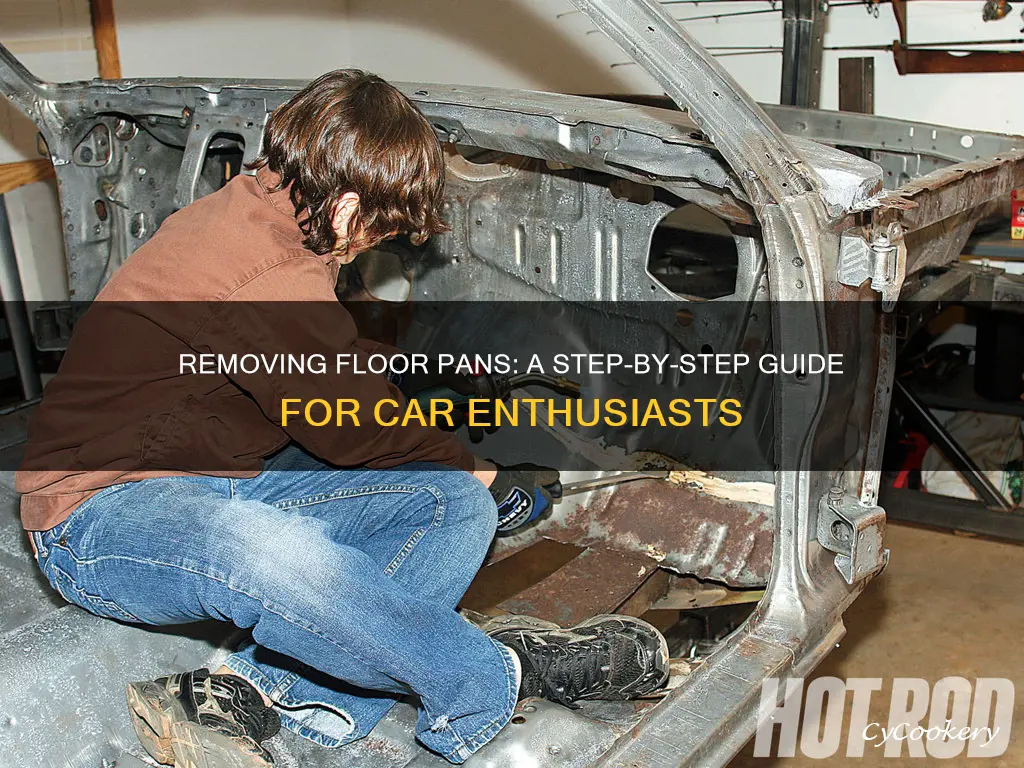

Working on your car's floor pans can be a messy job, so it's advisable to choose a suitable workspace, such as a garage or outdoor area, and lay down a tarp or old sheets to catch any falling debris. Additionally, ensure you have the necessary tools for the job. Basic tools include a grinder with a wire wheel, a welder, a body hammer, a cutting wheel, sheet metal pliers, a drill, and bits.

Remove Interior Components

To access the floor pans, you'll need to remove the interior components that may obstruct your work area. This includes taking out the seats, carpeting, and any other items covering the floor pans. Be sure to set these components aside safely to avoid damaging them during the restoration process.

Strip Away Old Seam Sealer

Using a scraper or appropriate tool, remove as much of the old seam sealer from the floor pans as possible. This step is crucial to ensure a clean surface for the next steps in the restoration process.

Clean and Treat the Surface

Utilise a wire wheel attachment on your grinder to grind off any remaining surface rust. Pay close attention to affected areas and ensure you create a smooth, rust-free surface. Once you're satisfied, use a rust prevention product, such as POR-15 Metal Prep, to treat the surface. This step is vital to inhibit further rust formation and prepare the surface for the next steps.

Apply a Rust Preventative Sealer

After cleaning and treating the surface, it's time to apply a rust preventative sealer. Using a foam brush, carefully apply two thin coats of a trusted sealer, such as POR-15 Rust Preventative Sealer, to the floor pans. Allow ample time for the sealer to cure, typically around four to five hours.

Consider Patching or Replacement

If the rust damage is extensive and goes beyond surface rust, you may need to consider patching the affected areas or replacing the entire floor pan. Patching involves using patch panels to cover the damaged sections, while replacement entails installing a new floor pan altogether. The decision depends on the severity of the rust and your personal preference.

Finalise the Process

Once you've completed the necessary repairs or replacements, ensure you test the car to ensure it's roadworthy. Take it for a test drive and carefully listen for any unusual noises. Check for any leaks and ensure that all components are securely fastened. If you're satisfied that everything is in order, you can then focus on restoring the interior of the car, including reinstalling the seats and carpeting.

Remember, removing rust from car floor pans can be a time-consuming and intricate process. Don't hesitate to seek professional assistance if you feel uncomfortable or unsure about any steps. Your safety and the integrity of your vehicle should always come first.

Pan-Seared London Broil Perfection

You may want to see also

Patching vs. replacing floor pans

Patching versus replacing floor pans is a difficult decision in any car restoration project. The decision depends on several factors, including the extent of the damage, cost, availability of parts, and your skill level. Here is a detailed comparison to help you make an informed choice:

Patching Floor Pans

Patching a floor pan is a viable option when dealing with minor rust damage. Patch panels are typically used to cover small areas of rust on your vehicle. They are meant to be used on portions or sections of a panel. While they can be a quick fix for isolated rust spots, they may not provide a perfect fit and finish. Patch panels are ideal when you need to make a small repair without disassembling the entire body of the car. This can be a cost-effective solution as it requires less labour and can be installed with the body still on the frame.

Replacing Floor Pans

Replacing the entire floor pan is often the preferred method for more extensive rust damage. It involves removing the old floor pan and installing a new one. This option can be more labour-intensive, especially when compared to a single patch panel. However, it provides a more comprehensive solution and can save time in the long run. Full one-piece pans attach in the factory location, requiring less finish work than multiple patch panels. They also offer better quality and can increase the value of your restoration project.

Factors to Consider

When deciding between patching and replacing floor pans, consider the following:

- Damage Assessment: Evaluate the extent of the rust damage. If there are only a few small holes, patching may be sufficient. For larger areas of rust or structural damage, replacement is often the better choice.

- Parts Availability: Check what parts are available for your specific make and model. In some cases, partial pans or full one-piece pans may not be readily available, limiting your options.

- Cost: Compare the cost of parts and labour for both patching and replacing. In some cases, a one-piece floor pan may be more cost-effective, especially if it reduces the overall labour time.

- Skill Level: Consider your skill level and the tools you have available. Replacing floor pans is a basic sheet metal job that can be suitable for beginners, but it does require some welding skills.

Remember, the key is to make repairs that improve the appearance, reduce labour, and lower costs. Be prepared to change directions if necessary, as initial assessments may not always reveal the full extent of the damage.

Gotham Steel Granite Rock Pan: Pros and Cons

You may want to see also

Using butt welds vs. spot welds

When removing and replacing floor pans in a car, there are several options for how to weld the new pans in place. The original floor pans in most American-made cars are held in place with spot welds. When replacing the floor pans, you can choose to replicate this method, or use butt welds, or a combination of both.

Spot Welds

Spot welds are created by using a special spot weld cutting tool to drill out the welds. This is a slow process, and it is important to go slowly to avoid breaking the cutting teeth. Before drilling, it is recommended to centre-punch the spot weld to prevent the cutter from "walking" off its mark. It is also helpful to spray a little cutting fluid or WD-40 on the cutting tip to keep it cool.

Butt Welds

Butt welding is considered the "right way" to do a replacement and will result in a stronger weld. To butt weld, you need a thin gap between the pieces. It is important to control heat warpage during the process to avoid panel warping. This method is more time-consuming and tedious but will result in a better finish.

Combination

Some people choose to use a combination of both spot and butt welding when replacing floor pans. This can involve spot welding the new panel in place and then running a complete bead around the panel. This method allows for a stronger weld while still replicating the original spot welds.

Pan-Seared Chicken: Golden, Juicy Perfection

You may want to see also

Removing spot welds

Spot welds can be removed using two methods: the drill bit method and the spot weld cutter method. The drill bit method is the least resource-dependent, requiring only a drill, some drill bits, and a center punch. The spot weld cutter method, on the other hand, requires a spot weld cutter, a center punch, and a grinder.

For the drill bit method, the first step is to locate the spot welds by inspecting the joint for small dimples where two pieces of sheet metal overlap. Once located, use a center punch to mark the weld. Then, enlarge the impression with a small drill bit, creating a dimple to guide the larger drill bit. Finally, use the larger drill bit to roll on the tip of the weld, stripping away the spot weld. If you don't want to remove it entirely, you can thin out the metal and then use a hammer and chisel to separate the pieces.

The spot weld cutter method is faster but requires more tools. First, locate and mark the welds with a center punch. Then, use a spot weld cutter with a centering pin to apply pressure at a moderate speed. It is important to work slowly to avoid issues such as the teeth biting unexpectedly, overheating the bit, or cutting through both panels. Once the weld is removed, the spot weld cutter will leave the weld behind, which can be removed with a grinder.

Resting Steaks: Pan or Oven?

You may want to see also

Sealing floor pans

When sealing floor pans, it is important to first prepare the metal surface by removing any rust and old sealant. This can be done using a wire wheel or chemical rust removers such as phosphoric acid or naval jelly. Once the metal is clean and free of rust, a primer or metal prep product can be applied to further protect the metal and provide a better surface for the sealant to adhere to.

After the metal surface has been prepared, it is time to choose a sealant product. There are many options available, including seam sealers, urethane caulking, gutter seam sealers, and roofing tar. Some popular brands include 3M, Lord Fusor, and POR-15. It is important to choose a product that is flexible, paintable, and will adhere well to metal and paint.

When applying the sealant, it is important to mask off the areas to be sealed and to apply the product in thin coats to avoid cracking and shrinking. The sealant can be applied from the top or bottom of the floor pan, and it is recommended to seal both sides for the best protection. After the sealant has been applied, it is important to allow it to cure completely before moving on to the next step in the restoration process.

Additionally, it is worth noting that some people choose to weld their floor pans in place before sealing, while others prefer to use an adhesive or glue to attach the new floor pans. In either case, it is important to ensure that the floor pans are securely attached and that there are no gaps or seams that could allow moisture to enter and cause rust.

Stainless Steel Pans: Removing Dark Stains

You may want to see also

Frequently asked questions

If you only need to replace a small section of your floor pan, you can use a patch panel. This is a good option if you only need to cover a small area and want to save the original metal on your car. You can trim the patch panel to cover only the damaged section.

If the damage is more extensive, you can choose to replace the entire floor pan with a one-piece panel. This option may be more cost-effective and require less finish work than using multiple partial panels.

The tools and materials you need to replace a floor pan can vary depending on the method you choose. In general, you will need items such as a welder, cutting tools, grinding tools, and rust prevention products. If you are fabricating your own patch panels, you will also need materials like sheet metal and hand tools.