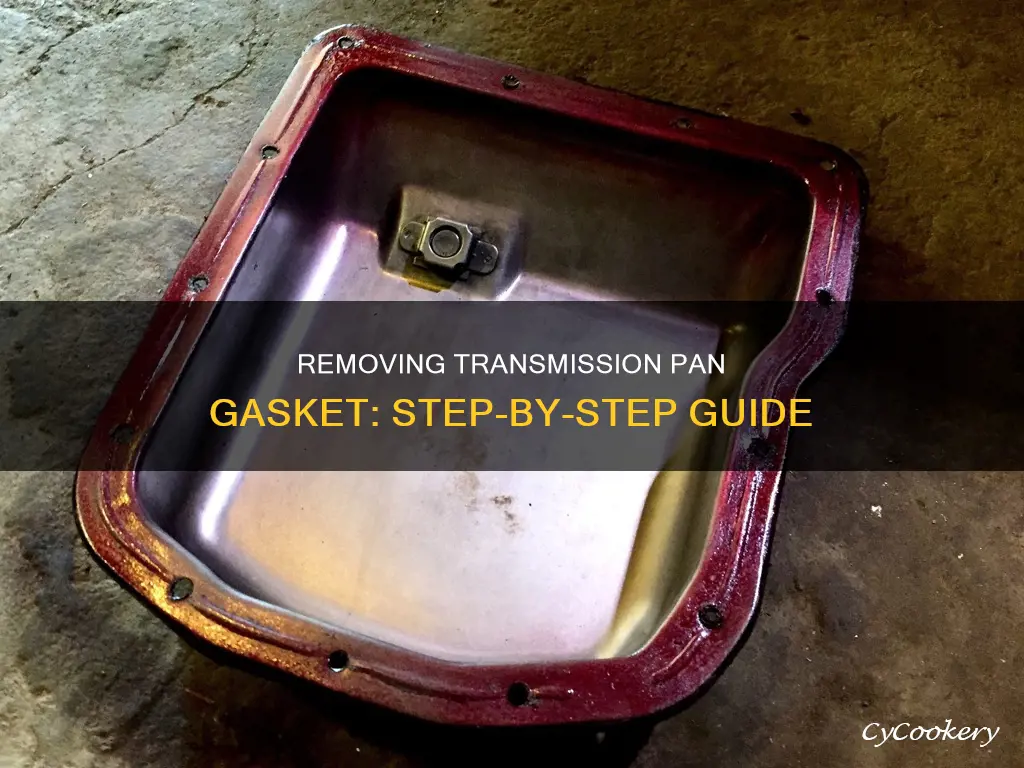

Removing a gasket from a transmission pan is a simple task that can be done in about 30 minutes with basic tools. The transmission pan gasket is a rubber gasket that seals the gap between the transmission housing and the transmission pan, preventing transmission fluid from leaking. To remove the gasket, you will need to jack up the car, drain the transmission fluid, remove the pan, and then use a gasket scraper or razor blade to scrape off the old gasket. It's important to clean the mating surfaces and check the old transmission pan for flatness before installing a new gasket.

| Characteristics | Values |

|---|---|

| Tools required | Rubber gloves, hand tools, inch-pound torque wrench, jack, jack stand, 14 mm wrench, 10 mm socket, small hammer or mallet, razor blade, putty knife, nylon wire wheel, drill, screwdriver, gasket scraper, gasket adhesive, transmission fluid |

| Steps | Drain the fluid, remove the pan and old gasket, clean the mating surfaces, check the old transmission pan for flatness, install the new transmission pan gasket and pan, torque the bolts, refill your transmission and set the transmission fluid level |

| Cost | $10-$50 for the part, $150-$300 for labour |

What You'll Learn

Jack up the car and use a wrench to loosen the drain and filler plug

Jacking up your car is an essential step in removing the gasket from your transmission pan. This process will give you access to the underside of your vehicle, allowing you to loosen the drain and filler plug. Here is a detailed guide to help you through the process:

Firstly, park your car on a flat surface to ensure stability. If your car has low clearance, use jack slopes or set it up with two jacks instead of one. This is an important safety measure to prevent the car from falling and causing serious injuries.

Now, you can begin the process of jacking up your car. Place the jack in the appropriate position, following the instructions for your vehicle's specific jack points. Once the jack is in place, start cranking it slowly until your car is lifted to a height that allows you to comfortably crawl underneath. Remember to engage the jack's safety mechanism to prevent accidental lowering.

With the car securely jacked up, locate the drain and filler plug. The drain plug is usually near the front of the engine, while the filler plug is typically located above the engine. Before proceeding, ensure you have the necessary tools, such as a wrench that fits the plugs, a socket set, and a drain pan.

To loosen the drain plug, use the appropriate wrench and turn it counterclockwise. Once it's loosened, you can finish removing it by hand. At this point, allow the oil to drain completely into the drain pan. Clean the screw and plug opening before proceeding.

Next, locate the oil filter, usually found on the side of the engine. Remove the oil filter, being cautious as it may be hot. Clean the area thoroughly, especially where the oil filter was installed.

Now, it's time to reinstall the drain plug. Before doing so, replace the drain plug gasket to ensure a tight seal. Reinstall the drain plug using the wrench, but avoid overtightening it.

The final step is to add new oil. Remove the filler cap and position a funnel at the opening. Refer to your car's manual to determine the correct oil capacity, typically around four to five quarts. After adding the oil, replace the filler cap.

Start the engine and let it run for a minute. Check the dipstick to ensure the oil level is correct. If needed, add more oil. Finally, check for any leaks near the oil drain and tighten the plugs or oil filter if necessary.

Bread Baking Basics: To Depan or Not to Depan?

You may want to see also

Remove the pan and old gasket

Removing the transmission pan and old gasket is a straightforward process, but it requires attention to detail and careful handling. Here is a step-by-step guide:

First, ensure you have the necessary tools and safety equipment. This includes rubber gloves, hand tools, and an inch-pound torque wrench. It is also important to have a drain pan to catch any fluid that spills out.

Next, safely raise the vehicle to provide enough space to crawl under the transmission. Place the drain pan under the transmission oil pan. If your transmission has a drain plug, remove it and allow the fluid to drain. If not, you can loosen the pan to drain the fluid. Remember, even if you have drained the transmission before, it is advisable to drain it again to ensure no fluid remains.

Now, we will move on to removing the pan and old gasket. Loosen and remove the bolts around the transmission pan, except for the corner bolts. Leave the corner bolts slightly loosened so that the pan can hang and prevent fluid from splashing everywhere. Use a small, flat screwdriver to carefully separate the oil pan from the transmission case. The pan might stick to the transmission or fall off as the last bolt is removed, so be cautious and prepared.

Once the pan is removed, you can begin cleaning the mating surfaces. Use a gasket scraper or plastic tools to remove the old gasket material from the pan and the transmission. If the gasket is stuck firmly, you may need to use a razor blade or steel wool to scrape it off gently. Be careful not to scratch or damage the metal surfaces.

After removing the old gasket, thoroughly clean the inside of the pan. Pay attention to any magnets that may be present, as they can attract metal shavings or fragments. Some metal material on the magnet is normal, but excessive shavings could indicate internal gear damage. Ensure the pan is clean and dry before proceeding to the next step.

Finally, inspect the old transmission pan for any warping or damage. Older pans can sometimes warp around the bolt holes, especially if prying was necessary during removal. If the pan is warped or bent, it may need to be replaced or pounded flat, ensuring a smooth mating surface for the new gasket.

By following these steps, you will have successfully removed the transmission pan and old gasket, setting the stage for installing a new gasket and pan. Remember to work cautiously and refer to your vehicle's manual for any specific instructions or variations for your particular model.

Pan Safety: Always Pan's Health Risks?

You may want to see also

Clean the mating surfaces

When it comes to cleaning the mating surfaces of a transmission pan and gasket, there are a few key steps and techniques to keep in mind. Here are some detailed instructions to ensure a thorough and effective cleaning process:

Firstly, it is important to understand that the mating surfaces of the transmission and the pan should be clean, dry, and free of any debris or residue. This includes gasket material, which can often be removed using a razor blade. For more stubborn residue, a wire brush or metal-brush sandpaper can be used. It is important to avoid using abrasive pads, as these can create an inconsistent surface finish and leave trace particles that can adversely affect other components.

Once the mating surfaces are free of residue, it is important to clean them with a suitable solvent. Brake cleaner is often recommended for this purpose, as it evaporates quickly and leaves no residue. Other solvents such as acetone can also be used, as long as they do not leave any residue behind. Using a clean rag, apply the solvent to the mating surfaces, ensuring that they are thoroughly cleaned.

After cleaning, it is important to allow the mating surfaces to dry completely before proceeding with the gasket installation. This will help ensure a good seal and prevent leaks.

Additionally, it is worth noting that some sources recommend checking the mating surfaces for flatness after cleaning. This can be done using a feeler gauge or straightedge to ensure that the surfaces are smooth and even, which is crucial for a proper seal.

By following these steps and techniques, you can effectively clean the mating surfaces of a transmission pan and gasket, ensuring a leak-free gasket installation.

Salad Pan Portioning: How Much Is Enough?

You may want to see also

Check the old transmission pan for flatness

To check the old transmission pan for flatness, you can try the following methods:

- Place the pan on a flat surface without the gasket and observe any gaps.

- Use strips of paper to identify uneven gaps with the gasket installed.

- Trace the gasket on a thick piece of MDF, cut it out, and then place the pan on the MDF with the metal tabs hanging off the edges.

- Fill the pan with water to just below the mating surface and level it with a dead blow mallet or by sliding it gently side to side. Fill the pan slowly with water by wicking it down the centre until the water reaches the rim of the mating surface. Observe any low spots.

- Use a nylon wire wheel on a drill to smooth out the surface.

- Tap the warped areas with a hammer.

- Apply pressure exactly opposite to the original damaging pressure to undo warping caused by bolt-overtightening.

- Use a bag of sand to level the mating surface. Break open the side of the bag and place the pan on the sand, keeping it level.

It is important to ensure the transmission pan is flat before reinstalling it. Older, thinner pans can warp around bolt holes, and prying to remove the pan can also cause bending or marring. In some cases, the surface can be pounded flat, while other times the pan may need to be replaced.

Hot Pot Culture in Iceland: A Warming Tradition

You may want to see also

Install the new transmission pan and gasket

Now that you've removed the old gasket, it's time to install the new transmission pan and gasket. Here's a detailed guide to help you through the process:

Prepare the New Gasket and Pan:

Before you begin, it's important to select the right type and brand of gasket for your transmission. Research and choose a gasket that will provide a good long-term seal, such as a rubber-coated metal gasket or a properly formed liquid gasket. Place the new transmission pan gasket on the pan, ensuring it's positioned correctly. Most transmission pans are not symmetrical, so the gasket will only fit one way.

Apply Gasket Adhesive:

Use a good spray-on or paint-on gasket adhesive to keep the gasket in place. This will ensure that the gasket remains secure and doesn't cause any issues with the transmission. Avoid using a gasket sealer, as fragments can come loose and cause damage to the transmission internals.

Adjust the Pan if Needed:

If the transmission pan was warped during the removal process, you may need to adjust its fit before installing the new gasket. This can be done by gently bending the pan back into shape or, if necessary, replacing it with a new one.

Install the New Pan and Gasket:

Lift the transmission pan with the new gasket into place. Ensure the pan is secure and doesn't cock to one side. Replace the bolts on the transmission pan, working in a star pattern from the corners. Be careful not to over-tighten the bolts, as this can distort the metal and cause fluid leaks.

Refill the Transmission Fluid:

Locate and remove the transmission dipstick. Use a funnel to add the recommended transmission fluid to the dipstick tube. Be sure to use the correct brand and formulation of fluid as advised by the manufacturer. Start the engine and shift through the gears several times, allowing the transmission to engage fully before shifting to the next gear.

Check the Fluid Level:

Once the engine and transmission have warmed up, check the fluid level with the engine running and the vehicle parked on a level surface. Remember not to overfill the transmission.

By following these steps, you can successfully install the new transmission pan and gasket, ensuring a secure and leak-free transmission system.

Emeril Lagasse's Forever Pans: Worth the Price?

You may want to see also

Frequently asked questions

You will need rubber gloves, hand tools, and an inch-pound torque wrench.

Use a gasket scraper or razor blade to remove the old gasket from the pan and the transmission.

Clean the mating surfaces and check the old transmission pan for flatness.

A bad transmission gasket will cause leaking transmission fluid and transmission performance problems.

Transmission gaskets are usually replaced once every 30,000 to 100,000 miles.