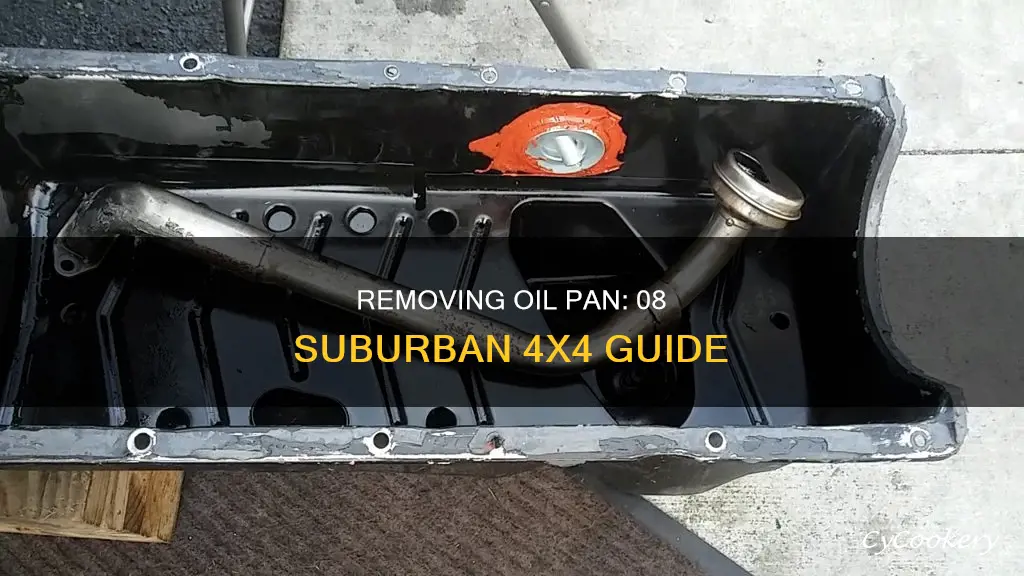

Removing the oil pan from a 2008 4x4 Suburban is a complex and time-consuming task. The process involves multiple steps, including removing the front differential assembly and crossbar brace, supporting the front drive axle with a jack, and draining the engine oil. It is also important to note that the oil pan gasket should not be reused and that foreign material should not enter the oil passages during the removal process.

What You'll Learn

Remove the front differential assembly and crossbar brace

To remove the front differential assembly and crossbar brace of a 2003 6.0-liter Suburban 4x4, follow these steps:

First, remove the front differential assembly. If your Suburban is equipped with four-wheel drive (4WD), remove the inner axle housing nuts and washers from the bracket. Support the front drive axle with a suitable jack. Next, remove the differential carrier lower mounting bolt and nut, followed by the differential carrier upper mounting bolt and nut. Now, lower the front drive axle.

At this point, you can proceed to remove the crossbar brace. Start by removing the transmission cover bolt. If your vehicle is equipped with an oil pan skid plate, remove the corresponding bolts and the skid plate itself. Now, remove the crossbar bolts and the crossbar itself.

With these steps completed, you will have successfully removed the front differential assembly and crossbar brace on your 2003 6.0-liter Suburban 4x4.

Please note that this process may vary slightly depending on the specific model and configuration of your vehicle. Always refer to the appropriate service manual or consult a qualified mechanic for more detailed instructions.

Baking Pan Sizes: Round Pans

You may want to see also

Remove the transmission cover bolt

To remove the transmission cover bolt as part of the process of removing the oil pan on a 2008 Suburban 4x4, follow these steps:

First, disconnect the negative battery cable. Then, remove the underbody shield from the vehicle. If your vehicle is equipped with four-wheel drive (4WD), you will also need to remove the inner axle housing nuts and washers from the bracket. Support the front drive axle with a jack. Next, remove the differential carrier lower mounting bolt and nut, followed by the differential carrier upper mounting bolt and nut. Lower the front drive axle.

At this point, you can remove the oil pan underbody shield, as well as the cross brace if your vehicle has one. Drain the engine oil and remove the engine oil filter. Now, you can remove the lower transmission-to-oil pan bolts. Disconnect the oil level sensor electrical connector and remove the front wiring harness retainer bolts. Remove the engine wiring harness retainer bolts from the engine oil pan.

Next, remove the engine oil cooler pipe to oil pan bolt. Remove the transmission oil cooler pipe retainer and bolt from the oil pan. Finally, you can remove the left and right closeout cover bolts.

How to Prevent Chocolate Chip Cookies from Sticking

You may want to see also

Drain the engine oil and remove the engine oil filter

To drain the engine oil and remove the engine oil filter, follow these steps:

First, loosen the oil fill cap to help the oil drain more easily. This is a round cover at the top of the engine that covers the hole where you check your oil level or pour oil in. You can do this by twisting it counterclockwise. Make sure your engine is off before you begin this procedure. If the engine is hot, wait at least 30 minutes before starting. If it's cold, let it warm up for 2-3 minutes, then shut it off.

Next, place an oil drain pan underneath the oil drain plug. The drain plug is usually a square nut, located beneath the engine block on the lowest point of the oil pan attached to the underside of the engine block. It will usually be at the bottom or side of the oil pan. It may be located near the crankshaft, which is housed inside a casing attached to the underside of the engine block.

After that, remove the oil plug to drain the oil, then replace it. Use a square-end wrench to loosen and remove it. Let the oil drain into the pan until it stops trickling out, which may take 10-30 minutes. Remember to put the oil plug back in when you're done. If your oil drain plug has a gasket, replace it with a new one before replacing the plug to ensure a tight fit and seal.

Now you need to find the oil filter. This is a metal cylinder attached to the engine block. Look on the top, bottom, and sides of the engine to locate the filter, which is usually black, white, blue, or orange and labelled as a filter. Check your vehicle's manual if you're unsure. Once you've found it, move the oil drain pan underneath the oil filter to catch any oil that drains out when you remove the filter.

You can now screw off the oil filter by hand, turning it counterclockwise until it comes off completely. Oil will start leaking out when you do this, so be prepared and consider putting on some work gloves first. If you can't loosen the filter by hand, use a filter wrench to do so. A filter wrench is a ratchet-type wrench designed to fit tightly around oil filters. Place it around the filter and ratchet to tighten, then twist counterclockwise to loosen.

Finally, put the old filter face down in the oil pan and let it drain for 24 hours. You need to let all the old oil drain out before you dispose of the filter. Throw it away in your regular trash after 24 hours, and recycle the oil at a service station, mechanic shop, or recycling centre.

Brining in Aluminum: Safe?

You may want to see also

Disconnect the oil level sensor electrical connector

Disconnecting the oil level sensor electrical connector is a crucial step when removing the oil pan on a 2008 Suburban 4x4. Here is a detailed guide on how to do this:

Locate the Oil Level Sensor: The oil level sensor is usually located on the side of the oil pan. It is responsible for monitoring the oil level in the engine and sending the information to the vehicle's computer system.

Access the Sensor: Before attempting to disconnect the electrical connector, ensure you have enough space to work comfortably. This may involve lowering the front drive axle and removing any components that may obstruct your access to the oil pan and the sensor. Refer to your vehicle's repair manual or seek advice from a qualified mechanic if you are unsure about the specific steps required for your vehicle.

Prepare the Necessary Tools: You will need a set of appropriate tools for the job, such as a socket wrench, screwdrivers, and possibly a jack to lift the vehicle and provide additional workspace. It is also recommended to have some rags or absorbent materials handy to deal with any spilled oil.

Disconnect the Electrical Connector: Once you have located the oil level sensor, you can proceed to disconnect the electrical connector. This connector provides power to the sensor and transmits the oil level data to the vehicle's computer. Gently pull the connector apart, being careful not to damage the wires or the connector itself. In some cases, you may need to press a release button or tab to detach the connector properly.

Secure the Connector: After disconnecting the electrical connector, ensure that it is securely fastened or tied away from any moving parts to prevent it from accidentally reconnecting or causing damage during the rest of the oil pan removal process.

At this point, you have successfully disconnected the oil level sensor electrical connector, and you can continue with the next steps in removing the oil pan. Remember to refer to a reliable repair guide or seek professional assistance if you encounter any difficulties or uncertainties during the process. Always exercise caution when working on your vehicle and follow safety protocols to prevent injuries or accidents.

Pan-Seared Tilapia: Spiced Perfection

You may want to see also

Remove the engine wiring harness retainer bolts

To remove the engine wiring harness retainer bolts from the engine oil pan of a 2003 6.0-liter Suburban 4x4, follow these steps:

First, remove the front differential assembly and crossbar brace. If your vehicle is equipped with four-wheel drive (4WD), remove the inner axle housing nuts and washers from the bracket. Support the front drive axle with a suitable jack. Remove the differential carrier upper and lower mounting bolts and nuts. Lower the front drive axle.

Next, remove the transmission cover bolt. If your vehicle has an oil pan skid plate, remove the bolts and the skid plate itself. Remove the crossbar bolts and the crossbar. Remove the transmission cover bolt and cover. Drain the engine oil and remove the engine oil filter. Reinstall the drain plug and oil filter until snug.

Now, you can remove the transmission bolt and stud on the right side, as well as the bottom bolt on the left side. If your vehicle is equipped with the 4L80-E automatic transmission, remove the transmission converter cover bolts. Disconnect the oil level sensor electrical connector.

Remove the battery cable channel bolt and slide the channel pin out of the oil pan tab. Remove the positive battery cable clip bolt.

At this point, you can remove the oil pan bolts. Do not allow foreign material to enter the oil passages of the oil pan, and cap or cover the openings as required. Drill out the oil pan gasket retaining rivets if necessary. Remove the gasket from the pan and discard it along with the rivets.

Now that the oil pan is removed, you can access and remove the engine wiring harness retainer bolts from the engine oil pan.

It is important to note that the alignment of the structural oil pan is critical. The rear bolt hole locations of the oil pan provide mounting points for the transmission bell housing. To ensure the rigidity of the powertrain and correct transmission alignment, the rear of the block and the oil pan must never protrude beyond the engine block and transmission bell housing plane.

Microwaving Pans: Removing Makeup Stains from Plastic Microwave

You may want to see also

Frequently asked questions

This is a time-consuming project. First, you will need to remove the front differential assembly and crossbar brace. Then, if your vehicle is 4WD, remove the inner axle housing nuts and washers from the bracket. Next, support the front drive axle with a jack and remove the differential carrier mounting bolts and nuts. Lower the front drive axle and remove the transmission cover bolt.

You will need to unbolt the lower differential bolt on the driver's side and the two bolts on the passenger side. This will allow the differential to swing down while still attached to the axles. You will also need to unbolt the two engine mount bolts, one on each side of the engine. Put a 2x4 on the harmonic balancer and jack up the engine, which will give you clearance to remove the pan.

You will need to remove the underbody shield, the cross brace, the engine oil and oil filter, the transmission-to-oil pan bolts, the oil level sensor electrical connector, the wiring harness retainer bolts, the engine oil cooler pipe-to-oil pan bolt, the transmission oil cooler pipe retainer and bolt, and the closeout covers and bolts.

The alignment of the structural oil pan is critical. The rear bolt hole locations of the oil pan provide mounting points for the transmission bell housing. Ensure that the rear of the block and the oil pan do not protrude beyond the engine block and transmission bell housing plane. Do not reuse the oil pan gasket.