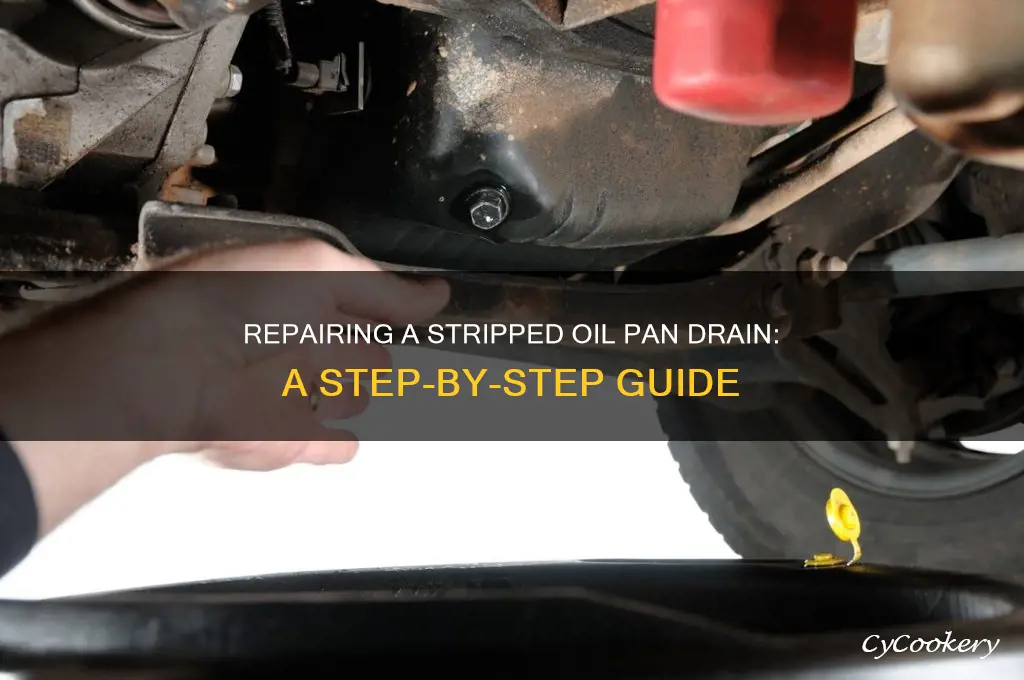

Stripped oil pan drain plugs are a common issue that can lead to major engine failure if not addressed promptly. The problem typically arises from over-tightening or using the wrong tools, resulting in crossthreading and overtightening. To fix a stripped oil pan drain, you'll need to identify the extent of the damage and gather the necessary tools and materials, which may include a car jack, wrenches, sockets, work gloves, anti-seize lubricant, and possibly replacement parts like gaskets or a new oil pan. Depending on the severity of the stripping, you can opt for re-threading the drain plug, using oversized drain plugs, installing a Helicoil, or replacing the entire oil pan. Each method requires careful attention to detail and specific steps to ensure a proper repair.

| Characteristics | Values |

|---|---|

| Problem | A stripped oil pan drain plug |

| Cause | Over-tightening, using the wrong tools, crossthreading |

| Solution | Use a quality oil drain plug repair kit, replace the oil pan |

| Alternative Solutions | Re-threading the drain plug, using oversized drain plugs, Helicoil installation |

| Tools Required | Car jack, jack stands, wrenches, sockets, work gloves, protective eyewear, anti-seize lubricant, replacement gaskets/sealing rings |

| Prevention | Use the correct tools, don't over-tighten, replace the drain plug washer/gasket regularly |

What You'll Learn

Use a wrench or socket to remove the drain plug

Using a wrench or socket to remove the drain plug is a common method to fix a stripped oil pan drain. Here is a detailed guide on how to do it:

Firstly, it is important to use the right tools. A socket or wrench of the appropriate size is crucial to avoid further damage to the drain plug. Make sure the wrench or socket fits securely over the plug. If you are working in a tight space, a ratchet can be used along with the socket.

Next, you need to loosen the drain plug by turning it counterclockwise. It is important to be cautious during this step to avoid overtightening the plug, which can lead to stripping. Turn the wrench or socket clockwise to tighten and counterclockwise to loosen.

In some cases, you may need to apply outward force on the plug to engage any remaining threads. This can be done using a flathead screwdriver wedged between the oil pan and the underside of the drain plug's head. Alternatively, you can use channel-lock pliers to rotate the plug counterclockwise while pulling outward.

Once the plug is loosened, you can continue to turn it counterclockwise and remove it by hand or with the wrench/socket. It is important to have a drain pan ready to catch the oil that will come out when the plug is removed.

By following these steps, you can effectively use a wrench or socket to remove a stripped oil pan drain plug.

Removing Quiche from a Muffin Pan: Easy Tricks

You may want to see also

Loosen the bolt by turning it counter-clockwise

To loosen the bolt by turning it counter-clockwise, you will need to apply force in the opposite direction to that used for tightening. This is because the bolt has been designed to tighten when turned in a clockwise direction.

The counter-clockwise direction for loosening is the standard direction for most bolts, screws, and nuts. However, it is important to note that there are exceptions, with some fasteners, such as bicycle pedals, requiring a clockwise turn to loosen due to their left-hand thread design.

When dealing with a stripped oil pan drain plug, the direction of turning is crucial. Turning the bolt counter-clockwise with a wrench or socket wrench is often the first step in attempting to remove a stripped plug. In some cases, you may need to apply outward force on the plug to engage any remaining threads. This can be achieved with a flathead screwdriver wedged between the oil pan's external surface and the underside of the drain plug's head.

If the head of the stripped drain plug is flush against the body of the oil pan, channel-lock pliers can be used. This involves rotating the plug counter-clockwise while simultaneously pulling outward. This method is often sufficient for removing the plug, even under challenging circumstances.

What Causes Oil Pan Leaks?

You may want to see also

Check threads on the drain plug for damage

Checking the threads on the drain plug for damage is an important step in the process of repairing a stripped oil pan drain. It is crucial to identify the extent of the damage and determine whether the drain plug needs to be replaced or if other repair methods can be employed.

To check the threads on the drain plug for damage, start by removing the plug from the oil pan. This can be done by rotating it in a counterclockwise direction using a wrench or socket wrench. In some cases, you may need to apply a slight outward force on the plug to disengage the remaining threads. This can be achieved with a flathead screwdriver wedged between the oil pan and the underside of the drain plug's head.

Once the drain plug is removed, carefully inspect the threads. Look for any signs of stripping, such as missing or damaged threads. If the threads appear to be in good condition and are not stripped, you may proceed to the next steps of the repair process. However, if the threads are damaged or missing, the drain plug will likely need to be replaced.

It is important to note that cross-threading and overtightening are common causes of damage to the threads on the drain plug. Cross-threading occurs when the plug is not installed straight and is forced into place. On the other hand, overtightening can happen when using a power tool or excessive force to tighten the plug. To prevent these issues, always use the correct tools, ensure proper installation techniques, and avoid over-tightening the drain plug.

If the threads on the drain plug are stripped, you may need to consider using a thread repair kit or seeking the assistance of a professional mechanic. They can guide you through the process of repairing or replacing the drain plug, ensuring that your oil pan is functioning correctly and preventing further damage to your engine.

Blue Steel Pizza Pan: Seasoning Secrets

You may want to see also

Use a thread-chaser tool to create new threads

Thread chasers are tools designed to repair and clean rusty or damaged threads. They are not meant for cutting new threads. Compared to taps and dies, thread chasers are less likely to get crooked or cross-threaded.

Thread chasers are scraping tools, sharpened only on the top surface. Continued sharpening will result in a hollow-ground or concave profile on top. A new chaser starts as a traditional scraper with a flat top and gradually transforms into a negative-rake tool, becoming less "grabby" and easier to use.

To use a thread chaser, simply fasten it on a threaded hole or bolt as you would with regular bolts or nuts. Then, turn the chaser slowly down the gunky or slightly damaged threads. Be gentle to avoid causing more damage.

Thread chaser sets typically include a storage case, with taps and dies that are colour-coded for easy identification.

Oil Pan Grease: Leak or Not?

You may want to see also

Use a bolt extractor socket to grip and release the socket

A bolt extractor socket is a specialty socket that can be used to remove a stripped oil drain plug with a rounded head. It features internal grooves that spiral. To use a bolt extractor socket, it may be necessary to gently hammer the socket onto the head of the drain plug to secure it. This causes the socket's internal grooves to bite into the head of the bolt, making it easier to extract.

When choosing a bolt extractor, it is important to select one that is the best fit for the job. Do not pick the most convenient or least expensive option, as this may lead to disaster. Instead, opt for a high-quality extractor from a reputable manufacturer.

Additionally, it is crucial to drill a hole as centre-accurate as possible. Starting with a small pilot hole and working your way up, hammer the extractor into the hole and begin turning it clockwise, then counter-clockwise. If the pilot hole is drilled off-centre, it can cause issues such as unevenly distributed force and increased torque, which can lead to the extractor breaking.

To apply force more effectively, use a straight splined extractor with a turn nut. This allows you to apply force closer to the broken bolt and distribute the load equally and broadly.

Pots and Pans: Toxic or Safe?

You may want to see also