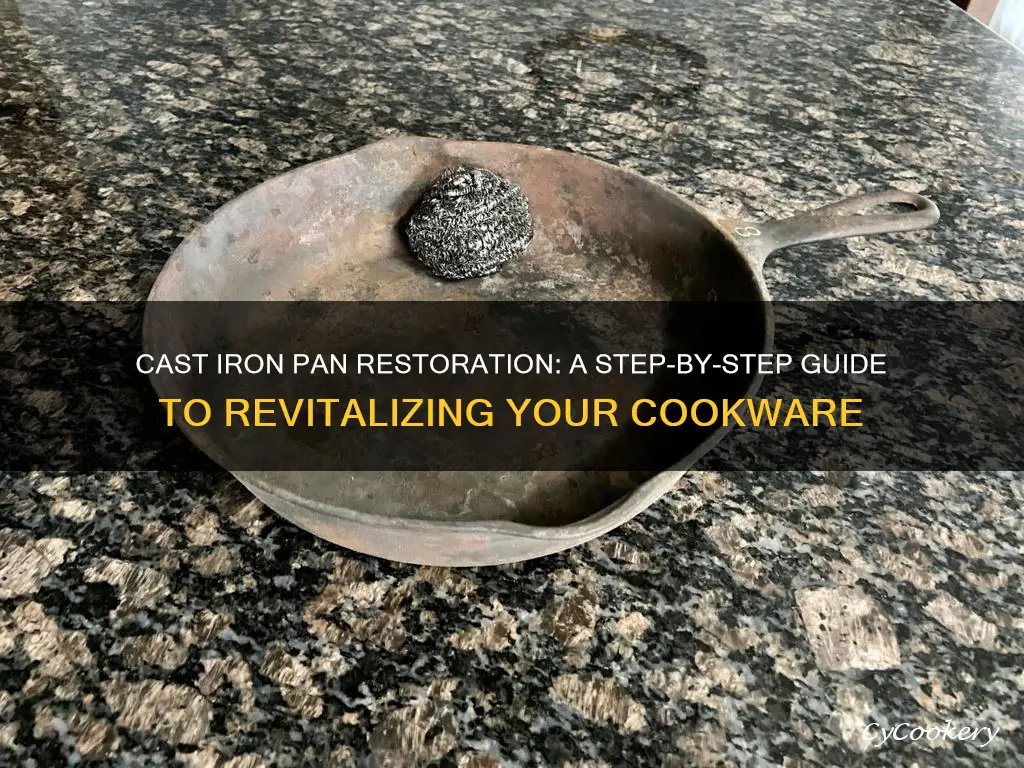

Cast iron pans are resilient and it's very hard to mess them up beyond repair. If your cast iron pan has seen better days, there are several ways to restore it to its former glory. Firstly, scrub and wash your pan with steel wool, then wash it with warm, soapy water. Dry your pan completely, either with a paper towel or by placing it on a low heat for a few minutes. Next, add a thin layer of cooking oil to the entire surface of the pan. Preheat your oven to between 350–500°F, and place the pan upside down on a rack with a sheet of aluminium foil underneath to catch any excess oil. Bake for 1 hour, then turn off the heat and allow the pan to cool in the oven.

| Characteristics | Values |

|---|---|

| First step | Scrub and wash the pan |

| Tools for first step | Steel wool, Lodge Rust Eraser, warm soapy water |

| Second step | Dry the pan |

| Tools for second step | Paper towel, lint-free cloth, stovetop |

| Third step | Add a thin layer of cooking oil to the pan |

| Fourth step | Preheat the oven to 450-500 degrees F |

| Fifth step | Place the pan upside down on the center rack of the oven |

| Sixth step | Bake for 1 hour |

| Seventh step | Turn off the heat and let the pan cool in the oven |

| Eighth step | Wash the pan with hot water (no soap) and dry it thoroughly after each use |

What You'll Learn

Removing rust with vinegar

Step 1: Preparation and Inspection

First, check the condition of your skillet. If there is only a light layer of rust on the interior and exterior surfaces, you may be able to gently brush it away and skip the vinegar soak. If the rust is deeper than the surface, it's time to soak the skillet in vinegar.

Step 2: Soaking Your Cast Iron Skillet in Vinegar

For the vinegar soak, combine equal parts white vinegar and water. Ensure the solution is enough to completely cover the skillet. The kitchen sink is a convenient place to do this. Soak the skillet for up to eight hours. Check the skillet every hour, and if the rust flakes off easily, the soak is done. If not, continue soaking and checking in hourly increments.

Step 3: Scrubbing the Surface

After the soak, use a soft scrub or brush to gently remove any residue rust. Be careful not to scrub too hard to avoid damaging the surface. Then, thoroughly dry the skillet with a paper towel or lint-free cloth. You can also place it on the stovetop on low heat for a few minutes to ensure it is completely dry.

Step 4: Seasoning the Cast Iron Skillet

Re-seasoning the skillet is important because the soaking and scrubbing process will remove the previous seasoning. To re-season, add a very thin layer of cooking oil to the entire surface of the skillet with a cloth or lint-free paper towel. Then, preheat the oven to 450-500 degrees Fahrenheit. Place aluminium foil on the bottom rack of the oven to catch any excess oil. Put the skillet upside down on the centre rack and bake for one hour.

Turn off the heat and allow the skillet to cool in the oven. This helps the seasoning further cure and adhere to the iron.

Tips to Avoid Rust Build-Up:

- Have a dedicated storage area for your cast iron cookware, keeping it away from sources of moisture.

- If stacking your cast iron, add a layer of paper towel between each item to prevent surface scratches.

- Never put cast iron cookware in the dishwasher.

- Always wash and dry your cast iron cookware by hand.

Tom Yum Hot Pot Sensations: A Culinary Journey to Thailand's Signature Dish

You may want to see also

Stripping old seasoning with lye

Lye is a great option for stripping old seasoning from cast iron pans. It is a common name for the alkaline compound sodium hydroxide, which can break down the polymerized oil that forms on cast iron pans. Here is a step-by-step guide on how to strip old seasoning using lye:

Step 1: Prepare the Lye Solution

Caution must be taken when working with lye. Wear heavy-duty, long-cuffed chemical-resistant gloves, and eye protection. Avoid any exposed skin on your arms and legs. Always add lye to water, never add water to lye, as this can cause a violent reaction. You can buy lye at hardware stores, usually in the form of drain cleaner. Add one pound of lye to five gallons of water.

Step 2: Soak the Cast Iron

Carefully place the cast iron pan in the lye bath. You can leave the pan in the lye solution indefinitely, and it will not damage the metal. Leave the pan for at least 24 hours. If you are dealing with extremely stubborn seasoning, you can leave it in the lye for weeks or even months.

Step 3: Remove from Lye Bath

After the soaking period, carefully remove the pan from the lye bath and transfer it to a bucket or tote. Use a nylon scraper or brush to gently remove thick clumps of dissolved seasoning.

Step 4: Rinse and Scrub

Transfer the pan to a sink or outdoor area and rinse it with cold water. Scrub the pan with steel wool and/or a handheld stainless steel brush. Never use brass brushes or any sort of power tool to clean the cast iron, as this will cause permanent damage. Repeat the rinsing and scrubbing steps as necessary.

Step 5: Neutralize and Dry

To neutralize any leftover lye, wash the pan with water and scrub it with citric acid or lemon juice. Wash the pan with water again and dry it thoroughly with a towel. You can also place the pan on the stovetop on low heat for a few minutes to ensure it is completely dry.

Once you have stripped the old seasoning with lye, you can move on to the next steps of restoring your cast iron pan, such as removing rust and re-seasoning the pan.

Standard Pan Pizza Size

You may want to see also

Cleaning with electrolysis

Electrolysis is a highly effective method for removing both rust and seasoning from cast iron pans. The process involves breaking down the pan's components using electricity.

To set up an electrolysis tank, you'll need a sturdy plastic storage container that can hold at least eight gallons of water, and a car battery charger. Additionally, you'll require a "sacrificial anode", a piece of iron or steel that will attract the electrical current flowing from the pan.

The water in the tank must be turned into an electrolyte to enhance its conductivity. This is achieved by adding Arm & Hammer Super Washing Soda™ (not baking soda) at a rate of 1-2 tablespoons per gallon of water.

When connecting the voltage source, remember that the black (negative) wire goes on the skillet. Ensure that the battery charger is manual or has a manual charge mode, as an automatic charger will shut down when it detects the electrolysis tank as a charged battery.

Suspend the pan in the water, ensuring it is fully submerged. Attach the black connector to the unsubmerged tip of the pan's handle, and the red connector to the sacrificial anode. The closer the pan is to the anode, the better the reaction, but ensure they don't touch.

You'll know the process is working when you see a mist of fine bubbles forming around the pan and the charger's amp meter reads towards the upper end of its scale. The electrolysis will convert red rust (ferric oxide) into ferrous oxide, or black rust. The sacrificial anode will also need to be maintained, as it will be coated and rotted by the process over time.

It's important to note that electrolysis is a line-of-sight process, meaning only the side of the pan closest to the anode will be cleaned. To clean all sides, you'll need to turn the pan occasionally. The process is complete when the pan's metal is bare and gray, with some darker staining remaining in spots that were particularly dirty.

Electrolysis is an effective method for restoring cast iron pans, but it does require some specialised equipment and knowledge of electrical safety.

Springform Pan Sizes for Your 6-Quart Insta Pot

You may want to see also

Drying and oiling

Once dry, the next step is to oil the pan. Rub the pan all over, inside and out—including the handle—with cooking oil. Neutral, unsaturated cooking fats with a high smoke point, such as vegetable, canola, or corn oil, are recommended. You want just a thin layer, not enough to drip or run when you tilt the pan. Thin layers are important for baking seasoning into the pan.

Buff the pan so thoroughly that it no longer looks greasy. Even a small amount of excess oil can pool during seasoning, forming hardened droplets on the cooking surface or turning sticky if left unused for a few days.

After oiling, place the pan upside down in a preheated oven set to 450-500°F. This will prevent oil from pooling on the cooking surface. Place a baking sheet or aluminium foil on the bottom rack of the oven to catch any excess oil. Bake for around an hour.

Turn off the heat and allow the pan to cool in the oven. This helps the seasoning to cure and adhere to the iron.

Pioneer Woman Cookware: Material Insights

You may want to see also

Baking in the oven

Once you've removed the rust from your cast iron pan, it's time to re-season it. This will restore the protective layer of carbonized oil that keeps your pan from rusting in the future. Here's how to do it:

Start by drying your pan thoroughly. You can place it on the stovetop on low heat for a few minutes to ensure it's completely dry. Then, take a cloth or lint-free paper towel and apply a very thin, even layer of cooking oil to the entire surface of the pan, inside and out. Be careful not to use too much oil—you don't want it to drip or run when you tilt the pan. Thin layers are important for baking seasoning into the pan.

Next, preheat your oven to 450–500 degrees Fahrenheit. Place a sheet of aluminum foil on the bottom rack of the oven to catch any excess oil that may drip off during the process. Place your oiled pan upside down on the center rack of the oven. This will help prevent oil from pooling on the cooking surface.

Now, bake your pan for 1 hour. After the hour is up, turn off the heat and allow the pan to cool down completely inside the oven. This step is important because it allows the seasoning to further cure and adhere to the iron.

If your pan still looks dull after re-seasoning, simply repeat the process until it achieves a slight sheen. You can also use this method to remedy stickiness caused by excess oil build-up. Just place the pan upside down on the top rack of the oven and bake at 450–500 degrees F for 1 hour. Allow it to cool and repeat if necessary.

Lentils Done Right: Mastering the Water-to-Lentil Ratio for a Hearty Hot Pot

You may want to see also

Frequently asked questions

To remove rust, scrub the rusty sections with steel wool or a rust eraser, then wash the pan with warm, soapy water. Dry the pan thoroughly with a paper towel or lint-free cloth, then place it on the stovetop on low heat for a few minutes to ensure it's completely dry. Add a thin layer of cooking oil to the entire surface of the pan, then preheat your oven to 450-500 degrees F. Place aluminium foil on the bottom rack of the oven to catch any excess oil, and put your pan upside down on the centre rack. Bake for 1 hour, then turn off the heat and allow the pan to cool in the oven.

To remove old seasoning, use a product like Easy-Off, an oven cleaner that sprays a lye-based foam. Spray the foam all over the cookware, then seal it in a heavy-duty garbage bag and let it sit for 24 hours. Scrub the pans to remove the seasoning, and repeat the process until the pan is stripped down to its original metal surface.

To season your pan, first, ensure it is completely dry. Then, add a very thin layer of cooking oil to the entire surface of the pan with a cloth or lint-free paper towel. Preheat your oven to 350-500 degrees F. Place aluminium foil on the bottom rack of the oven to catch any excess oil, and put your pan upside down on the centre rack. Bake for 1 hour, then turn off the heat and allow the pan to cool in the oven. Repeat the baking step as needed until your pan has a semi-gloss finish.

To clean your cast iron pan, scrub it in hot, soapy water using a nylon scrub brush or fine steel wool scrubber. Dry the pan thoroughly inside and out, and ensure it remains dry to prevent rusting.