If you're looking to save a rusty oil pan, you're in luck! While the ideal solution is to replace the pan, it's not always necessary. If the damage isn't too extensive, you can simply repair it. Here's a step-by-step guide to help you get started:

First, loosen the oil pan drain plug bolt using pliers or a socket wrench. Remove the plug and drain the oil, collecting it in a container for hazardous waste disposal. Next, clean the exterior surface of the pan thoroughly, identifying all the rusty areas. Use metal-grade sandpaper to sand these areas, removing the rust and creating a rough surface. Treat severely rusted areas as weakened metal and strengthen them with steel epoxy.

If the leakage is caused by a hole, mix and apply a two-part epoxy, allowing each coat to dry before applying the next. Once the epoxy is dry, your repair is complete. Remember to replace the gasket if you remove the oil pan during the process.

Now, you might be wondering if there are any alternative methods. Well, one option is to brush off the rust and apply a coating of enamel or paint that seals and prevents further rust. This approach can be done on-site without removing the pan. However, if the rust is more severe, you may need to take additional steps, such as removing the pan for a thorough cleaning and applying a sealant.

What You'll Learn

Identify the cause of the rust

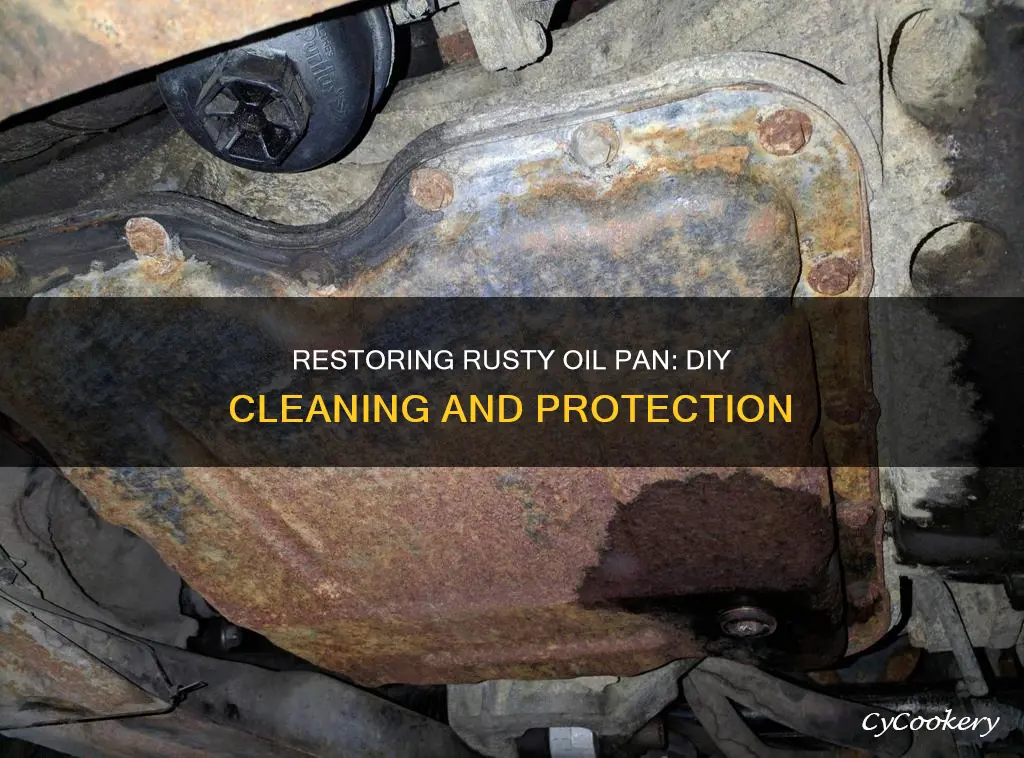

Rust on an oil pan is typically caused by minor damage to the metal and subsequent oxidation. This can be caused by the paint layer being broken or chipped, exposing the metal to the elements and initiating the rust cycle. The likelihood of this occurring depends on the quality of the steel and paint job, the amount of road salt in winter, the amount of debris the pan is exposed to, and how well-drained its parking spot is.

Rust can also be caused by drain plug mishaps, such as when the drain plug is mis-threaded or over-tightened during an oil change. This can cause the thin metal around the drain plug to warp, leading to rust and leakage.

To identify the cause of the rust on your oil pan, start by inspecting the exterior surface for any areas of flaking or chipping paint, as well as any signs of impact damage or debris accumulation. If the paint layer is compromised, this could be the entry point for moisture and oxygen, leading to rust formation.

Additionally, check the drain plug area for any signs of over-tightening or cross-threading. If the drain plug is not properly sealed, it can allow oil to leak out, leading to rust formation around the plug and potentially affecting the surrounding areas.

If you notice any areas of rust, use metal-grade sandpaper to sand down the affected areas, removing the rust and creating a rough surface. This will help you determine if the rust is superficial or if it has penetrated deeper into the metal.

By identifying the specific areas of rust and assessing the extent of the damage, you can make an informed decision about the best course of action for repairing or replacing your oil pan.

Water Heater Pan: Pipe It?

You may want to see also

Remove the oil plug bolt

Removing the oil plug bolt is a delicate process that requires careful attention to avoid further damage to the oil pan. Here is a detailed guide on how to remove the oil plug bolt from a rusty oil pan:

- Assess the Situation: Before attempting any repairs, it is important to evaluate the extent of the rust and determine if the bolt is salvageable. Check if the bolt is corroded or has locking compound on it. Assess whether the bolt is worth saving, as a rusted bolt that has lost its tensile strength may not be able to do its job effectively.

- Prepare the Work Area: Put on safety gear, including eye protection and a filter mask, to protect yourself from any debris or harmful substances. Ensure you have a container ready to collect any oil that will be drained from the oil pan during the process. Place a pan or container underneath the oil plug bolt to catch the drained oil.

- Loosen the Oil Plug Bolt: Use the appropriate tool, such as a socket wrench or pliers, to loosen the oil plug bolt. Turn the bolt counterclockwise to loosen it. Be cautious not to overtighten the bolt, as this can strip the threads and make it difficult to remove. If the bolt is already stripped, you may need to use vice grips or a bolt extractor socket to remove it.

- Remove the Oil Plug: Once the bolt is loosened, continue turning it counterclockwise to remove it completely. Collect any oil that drains from the oil pan into the container. If the bolt is difficult to remove due to rust, you may need to apply upward force or use a screwdriver to wedge the bolt out.

- Clean the Area: With the oil plug bolt removed, clean the area thoroughly. Use a stiff wire brush to remove any rust or debris from the bolt and the surrounding area. This step is crucial to ensure that the area is prepared for the next steps in repairing the rusty oil pan.

Remember to work carefully and patiently throughout the process. If you encounter any challenges, refer to online resources or seek advice from a professional mechanic.

Replacing Oil Pan in a 2001 Dakota 4.7: Step-by-Step Guide

You may want to see also

Drain the oil pan

Draining the oil from your pan is a crucial step in saving a rusty oil pan. Here is a detailed guide on how to do it effectively:

Step 1: Warm up the Engine

First, warm up your engine for 2 to 3 minutes. This helps to liquefy the oil, making it flow out easily when you drain it. Be careful not to overheat the engine, as you do not want it to be too hot to touch.

Step 2: Locate the Drain Plug

The drain plug is typically located under the oil pan at the bottom of the engine. It is usually a large nut or plug. If it is difficult to reach, you may need to crawl under the car or jack up the vehicle to access it easily.

Step 3: Place a Container

Place a suitable container under the oil drain plug to catch the draining oil. Make sure the container is large enough to catch all the oil and is specifically designated for hazardous waste disposal.

Step 4: Unscrew the Drain Plug

Using a rag or paper towels to protect your hand, unscrew the oil drain plug. Be ready to quickly move your hand away as the oil will start draining out once the plug is released. You can use pliers or a socket wrench, or an adjustable wrench for this step.

Step 5: Drain the Oil

Allow the oil to drain completely from the engine into the container. This may take a few minutes, depending on the amount of oil in the pan. Make sure to collect all the oil for proper disposal.

Step 6: Clean the Oil Pan

Once the oil has drained, clean the exterior surface of the oil pan thoroughly. Identify all the areas of rust and assess the extent of the damage. This will help you determine if the pan can be repaired or needs to be replaced.

Step 7: Sand the Rusty Areas

Use metal-grade sandpaper to sand all the rusted areas. Remove the rust and roughen the metal surface. Treat severely rusted areas as weakened metal and strengthen them with steel epoxy. This will help create a smooth surface for the next steps.

Step 8: Apply Epoxy

Mix a two-part epoxy according to the instructions and apply it to the metal surface. If there is a hole, you may need to apply two coats of epoxy. Let the first coat dry, and then apply the second coat over the hole and the entire sanded surface.

By following these steps, you will effectively drain the oil from your rusty oil pan and prepare it for further repair or replacement. Remember to always exercise caution when working with oil and to dispose of it properly at a designated hazardous waste disposal site.

Bamboo Spoons: Safe for Non-Stick Pans?

You may want to see also

Clean the exterior surface

To clean the exterior surface of a rusty oil pan, you will need to identify all the areas of rust. If the rust is only superficial, you can use a scouring pad or kitchen towel to rub about 1/3 cup of kosher salt into the surface of the pan until the spots of rust are removed. You can also use a mildly abrasive sponge, like a green scrub pad, or a scrubber made from palm fibres.

If the rust is more severe, you may need to start by soaking the pan in a mixture of equal parts water and distilled white vinegar. Ensure the entire pan is submerged, including the handle, and check the pan every 15 minutes. Remove the pan from the solution once the rust easily flakes away. This can take anywhere from one hour to eight hours, so frequent check-ins are important. Be careful not to soak the pan for too long, as the vinegar solution can start to eat away at the original cast surface of the pan.

Once the rust has been removed, wash the pan with mild dish soap and warm water, and dry it immediately and thoroughly with a kitchen or paper towel. You can also place the pan on the stovetop over low heat for a few minutes to ensure it is completely dry.

Understanding the Power Draw of Hot Pots

You may want to see also

Sand the rusted areas

Sanding is a great way to remove rust from your oil pan without using chemicals. It is a more labour-intensive method, but it is effective and affordable. Here is a step-by-step guide to help you through the process:

Step 1: Prepare the Oil Pan

Before you start sanding, make sure you have drained the oil from the pan and collected it in a container for hazardous waste disposal. Identify all the areas of rust on the exterior surface of the pan. You can use metal-grade sandpaper to sand the rusted areas, but it is recommended to use power tools for a more efficient and thorough job.

Step 2: Choose the Right Power Tool

Select the appropriate power tool for the job, such as a grinder, sander, oscillating tool, or drill. These tools will help you remove the rust and paint from the oil pan effectively. Choose the right attachment for your tool, such as flap discs, fibre discs, or sanders for large, flat areas. For seams, corners, and rounded areas, switch to wire wheels.

Step 3: Start Sanding

Begin sanding the rusted areas with a coarse abrasive to remove the rust and create a rough metal surface. Make sure to wear the appropriate safety gear, including eye protection and a respirator, to protect yourself from dust and debris. Work systematically, ensuring that you cover all the rusted sections.

Step 4: Switch to a Finer Grit

Once you have removed the rust and created a rough surface, switch to a finer grit sanding attachment. This step will help you smooth out the swirls and grooves left by the coarse grit. Continue sanding until you are satisfied with the smoothness of the surface.

Step 5: Finish with Wet/Dry Sandpaper

For the smoothest finish, it is recommended to finish sanding with 400-grit wet/dry sandpaper. This will help create an even and consistent surface, preparing the oil pan for the next steps in the repair process, such as applying an epoxy or paint.

Remember to take your time and work carefully when sanding the rusted areas of your oil pan. This process will ensure that you remove all the rust and create a smooth surface for the subsequent treatments, helping to extend the life of your oil pan.

Pyrex Pie Pans: Freezer-Safe?

You may want to see also

Frequently asked questions

The first step is to loosen the oil pan drain plug bolt using pliers or a socket wrench. Remove the plug and drain the oil pan, collecting the oil in a container for hazardous waste disposal.

Clean the exterior surface of the pan thoroughly, identifying all the areas of rust.

Sand all the rusty areas with metal-grade sandpaper, removing the rust and roughing up the metal. Treat severely rusty areas as weakened metal and strengthen them with steel epoxy.

Mix a two-part epoxy according to the instructions and apply it to the metal surface. If there is a hole in a groove, you will need two coats. Fill the groove with the first coat, let it dry, and then apply a second coat over the hole and the entire sanded surface.

Once the epoxy is dry, your oil pan repair is complete. Replace the gasket if you removed the oil pan for repair.