Porcelain glassware is elegant and functional, with a unique design that allows for cups to be nestled within a teapot to warm before serving tea. While porcelain is a type of ceramic, denser and less porous than other types of ceramic clay, it is also harder and more impervious to moisture. The composition of porcelain is highly variable, but it is typically made from the clay mineral kaolinite, fired at a high temperature to create a hard, white, translucent finish.

| Characteristics | Values |

|---|---|

| Composition | Porcelain is made from various clays and minerals. The clay mineral kaolinite is often a raw material, along with other materials such as feldspar, glass, bone ash, and quartz. |

| Appearance | Porcelain is a hard, white, translucent ceramic. |

| Durability | Porcelain is denser and less porous than ceramic, making it more resistant to moisture. It is also chip and crack-resistant, but can break if handled improperly or exposed to high temperatures. |

| Use Cases | Porcelain is commonly used for tea sets, mugs, and decorative glassware. |

What You'll Learn

Porcelain tea sets

For those who appreciate a more classic aesthetic, there are timeless porcelain tea sets with delicate floral patterns and gleaming gold trim. These sets often include essential pieces such as a teapot, teacups with saucers, dessert plates, and a sugar container with a lid and a creamer pitcher. Some sets even offer a matching porcelain tier cake stand, perfect for catered events or family gatherings.

If you're looking for something unique and whimsical, you can find porcelain tea sets with leopard prints, polka dots, or even monkeys! These sets add a touch of playfulness to your tea parties and are sure to be a conversation starter.

When choosing a porcelain tea set, you can also consider the number of people you intend to serve. Sets range from intimate tea for two settings to larger sets that serve up to six people. So, whether you're hosting an elaborate tea party or enjoying a quiet afternoon tea, there is a porcelain tea set to suit your needs.

Corelle Dinnerware Dessert Plates: A Sweet Addition to Your Dining Experience

You may want to see also

Manufacturing processes

The manufacturing process for porcelain glassware involves several steps, from the collection of raw materials to the final glazing and firing of the porcelain. Here is a detailed overview of the manufacturing processes involved in creating porcelain glassware:

Collection of Raw Materials

The first step in manufacturing porcelain glassware is gathering the necessary raw materials. The specific raw materials depend on the type of glass being produced. For porcelain glassware, the primary raw materials typically include clay, feldspar or flint, and silica. These materials are chosen for their small particle size and ability to develop glassy qualities when baked at high temperatures.

Preparation of Batch

Once the raw materials are collected, they are prepared for mixing. This involves crushing and grinding the materials into a fine powder using machines such as jaw crushers, hammer mills, and ball mills. The ground materials are then weighed accurately and mixed together in specific proportions to create a uniform mixture called the batch or frit.

Forming Processes

The batch is then subjected to one of several forming processes, depending on the type of ware being produced. These forming processes include soft plastic forming, stiff plastic forming, pressing, or casting. During this stage, the porcelain takes shape through techniques such as manual molding, wheel throwing, jiggering, or ram pressing.

Bisque Firing

After forming, the porcelain wares undergo a preliminary firing step called bisque-firing. This process involves heating the porcelain at a relatively low temperature to vaporize volatile contaminants and minimize shrinkage during the final firing.

Glazing

Following bisque firing, the porcelain wares are ready for glazing. Glaze is a decorative glass layer applied to the surface of the porcelain. It can be applied through various methods such as painting, dipping, pouring, or spraying. The choice of glazing technique depends on the desired effect and the type of ware being produced.

Firing

The final manufacturing phase is firing, which is a critical heating step that takes place in a kiln (a special type of oven). During firing, the porcelain is subjected to high temperatures, typically ranging from 2,650°F to 2,200°F for true porcelain. This step transforms the raw materials into a strong, vitreous material with a translucent and low-porosity finish.

Annealing

After firing, the porcelain glassware may undergo an annealing process to ensure gradual cooling and prevent thermal shock. This process helps relieve internal stresses built up during the firing and prevents the porcelain from breaking due to rapid temperature changes.

Quality Inspection and Finishing

Once the porcelain glassware has cooled, it undergoes rigorous quality inspections to identify any defects or imperfections. Automated machines or human inspectors check for cracks, inclusions, bubbles, or other issues. Finally, the porcelain glassware is packaged and prepared for shipping to customers.

Elegant Dining with Corelle's 16-Piece Dinnerware Set: A Clearance Steal

You may want to see also

Design and art

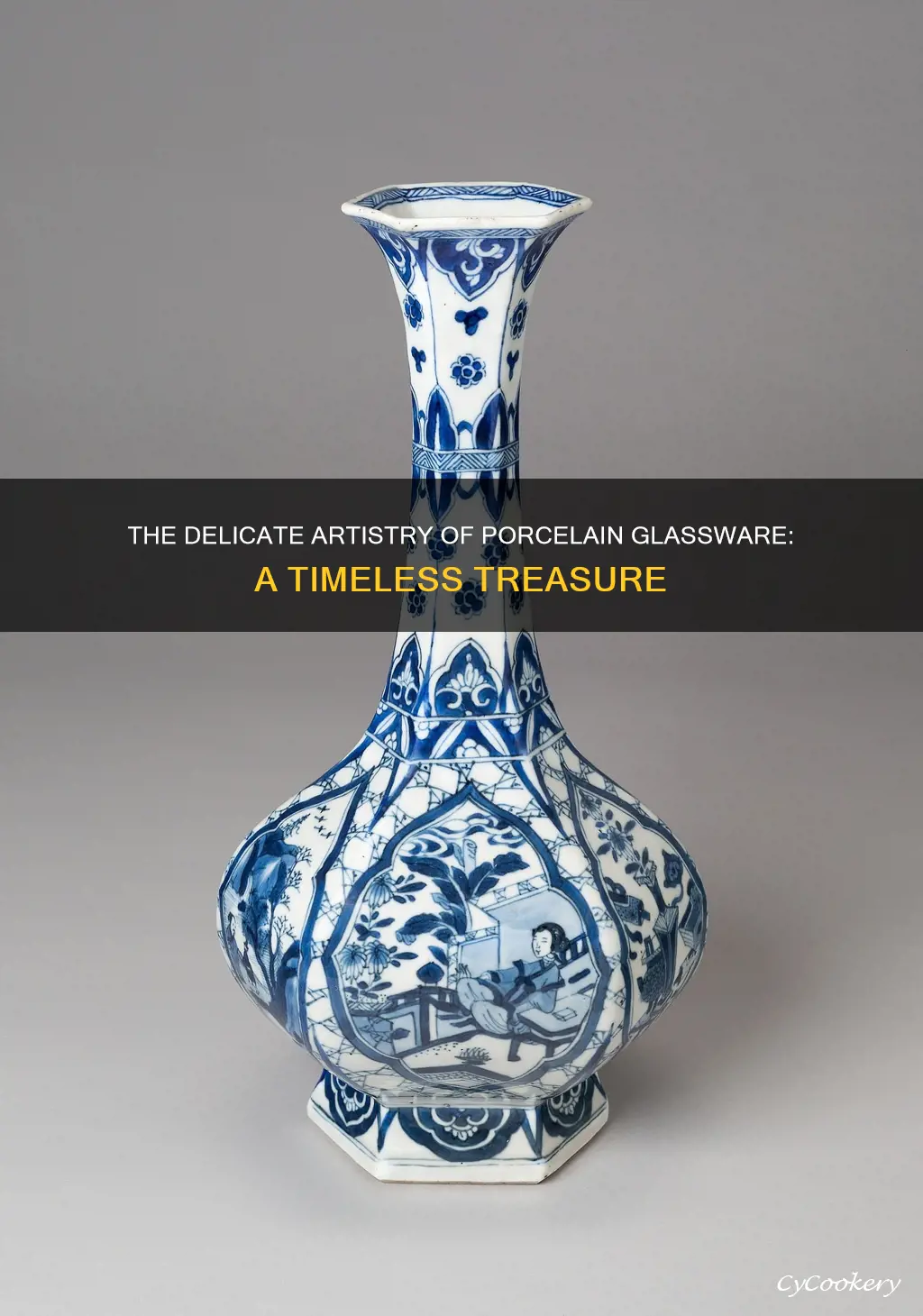

Porcelain is a type of ceramic that is made by firing clay and other materials, such as the clay mineral kaolinite, feldspar, glass, and bone ash. It is a hard, white, translucent substance that is denser and less porous than other types of ceramics. This makes porcelain ideal for use in glassware, as it is more durable and has a more refined appearance.

Porcelain glassware is often prized for its beauty and elegance. Its smooth, glossy surface and delicate appearance make it a popular choice for tableware and decorative items. The translucency of porcelain allows light to pass through, creating a soft, warm glow that is particularly flattering in table settings.

From a design perspective, porcelain glassware offers a unique combination of functionality and aesthetics. Its durability and chip-resistance make it suitable for everyday use, while its elegant appearance makes it ideal for special occasions. Porcelain glassware is also versatile in terms of style, as it can be produced in a variety of colours, shapes, and sizes to suit different tastes and purposes.

The design process for porcelain glassware typically involves a collaboration between artists, designers, and manufacturers. Artists and designers create the initial sketches and prototypes, considering factors such as form, function, and aesthetic appeal. Manufacturers then work to translate these designs into finished products, using specialised techniques and equipment to mould, fire, and glaze the porcelain.

One notable example of porcelain glassware design is the Design II Tea Service by Peter Saenger for Saenger Porcelain. This tea set has been featured in several episodes of the popular television series, "Star Trek: The Next Generation". The unique design of this tea set allows the cups to nestle into the pot, warming them before the tea is served, showcasing both the functionality and aesthetic appeal of porcelain glassware.

The Elegance of Fine China: Elevating Dining Experiences with Luxurious Tableware

You may want to see also

Durability and maintenance

Porcelain glassware is a durable and long-lasting option for tableware. Its high-temperature firing process makes it non-porous, strong, and suitable for daily use. Here are some key points about the durability and maintenance of porcelain glassware:

Durability

Porcelain is known for its strength and resistance to chipping and cracking. The high-temperature firing process, often above 2372 degrees Fahrenheit, results in a dense and durable product. This process also gives porcelain a smooth, glossy finish that is resistant to scratches and stains. However, it is important to note that porcelain can break, chip, or crack if mishandled or overheated in the microwave. Therefore, it is essential to exercise caution when using and handling porcelain items.

Maintenance

Porcelain glassware is generally safe for use in dishwashers, microwaves, and ovens, making it convenient for daily use. Its non-porous nature also means it is resistant to water damage and stains. However, special care should be taken with metal-accented porcelain, as some dishwashing detergents can damage the metal accents, and microwaving metal-rimmed porcelain is not advisable. Most manufacturers will provide specific care instructions for their porcelain products, so be sure to follow those guidelines.

Comparison with Other Materials

When compared to other materials, such as glass or ceramic, porcelain stands out for its durability and heat resistance. It is denser and less porous than ceramic, making it harder and more resistant to moisture. Porcelain is also generally lighter than glassware, making it easier to handle and stack. Additionally, porcelain has a more elegant and upscale appearance, making it suitable for formal dining occasions, while glassware is often preferred for casual settings.

Elegant Antique White Dinnerware Set for Memorable Dining Experiences

You may want to see also

Comparison with other materials, such as glass or ceramic

Porcelain, ceramic, and glass are all materials commonly used for glassware and tableware. While porcelain and ceramic are both manufactured from clay, porcelain is a type of ceramic that is harder and denser, with a more refined and purified clay composition. Porcelain is also fired at a higher temperature than ceramic, making it less porous and more impervious to liquid.

Glass, on the other hand, is a non-crystalline, amorphous solid made by melting sand with a mixture of soda, potash, and lime. Glass is known for its transparency, which sets it apart from porcelain and ceramic, which are typically opaque or translucent. Glass can also be moulded into a wider variety of shapes than porcelain or ceramic, making it a popular choice for drinkware, windows, and light bulbs.

Porcelain and ceramic, due to their more limited malleability, are often chosen for plates, bowls, and decorative items. They are also popular choices for insulation, as they are good at retaining heat. Porcelain, in particular, is known for its long-term durability and elegant design.

In terms of breakability, all three materials are susceptible to chipping and cracking if handled improperly or exposed to extreme temperatures. However, glass is generally more fragile and prone to shattering than porcelain or ceramic.

Corelle's Dinnerware Sets: A Complete Dining Solution for Families

You may want to see also

Frequently asked questions

Porcelain is a hard, white, translucent ceramic that is made by firing kaolin and other materials at a high temperature. It is not a type of glass.

Glass is a transparent substance made by melting sand with a mixture of soda, potash, and lime. Porcelain is made from clay and other materials, and it is harder and less porous than glass.

Porcelain is a type of ceramic, but not all ceramics are porcelain. Porcelain is made from more refined and purified clay, which makes it denser and harder than other types of ceramics.

Although porcelain is chip and crack-resistant, it can still break if handled improperly or if it gets too hot in the microwave.

Both glassware and porcelain can be used for tea sets. Porcelain is known for its elegance and durability, while glassware can be preferred for its transparency and versatility.