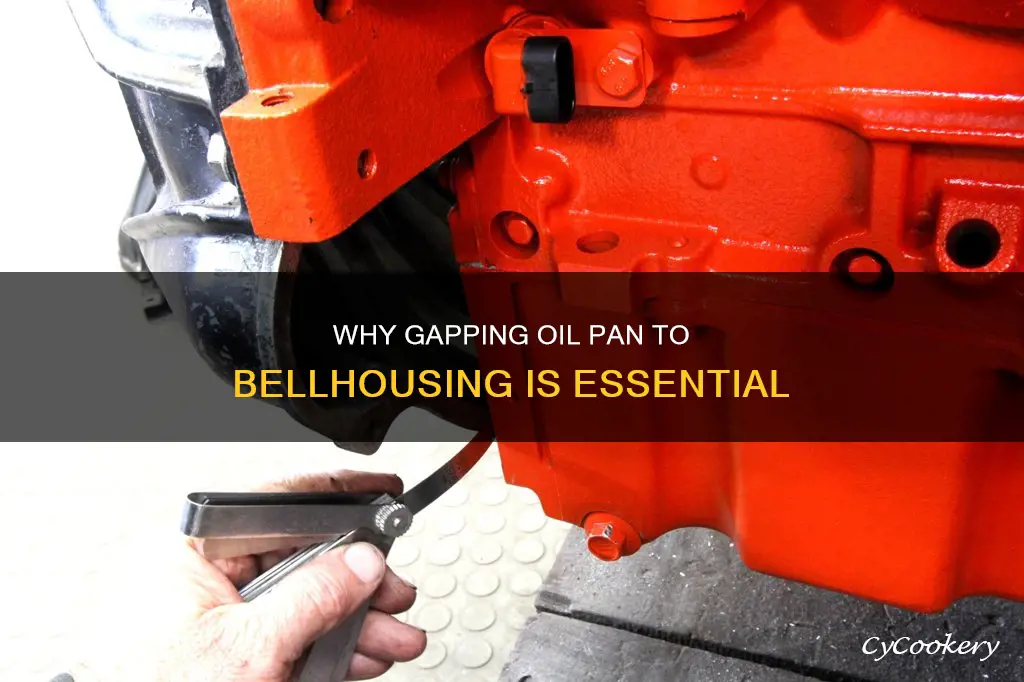

If you don't gap the oil pan to the bell housing, you may experience an oil leak. This is because the oil pan and bell housing need to be flush for a proper seal. If the bell housing is not sitting flat against the motor, it could lead to strange loading on the crankshaft and input shaft. This could potentially cause issues with the engine's performance and longevity. It is important to ensure that the oil pan and bell housing are properly aligned and sealed to prevent oil leaks and potential damage to the engine.

| Characteristics | Values |

|---|---|

| Oil leak | Oil dripping from the bottom of the bellhousing at the front of the transmission |

| Oil dripping from the bell housing | |

| Oil on the engine above the bellhousing | |

| Oil on the flywheel or flexplate | |

| Oil on the oil pan | |

| Oil dripping from the end of the oil pan | |

| Oil dripping from the start of the bell housing | |

| Oil dripping from the bottom of the bellhousing |

What You'll Learn

Oil leaks can be caused by a faulty rear main seal

The rear main seal is located at the back of the engine, where the crankshaft connects to the transmission. This location makes it hard to reach and usually requires removing the transmission to access it, which can be costly. The seal is typically made of silicone or rubber and can easily deteriorate, leading to oil leaks. These leaks can be caused by normal wear and tear, transmission alignment problems, or low oil levels.

A faulty rear main seal can cause oil to leak from the camshaft into the transmission bell housing. While this may start as a small leak, it can gradually get larger over time. If the seal is badly worn, it can cause a fast oil leak, quickly draining the oil reservoir and potentially leading to severe internal engine failures and expensive repairs. Therefore, it is important to address a faulty rear main seal as soon as possible.

To determine if you have a rear main seal leak, check for oil leaks where the transmission connects to the engine, frequent low oil levels, or oil stains on your driveway. It is important to note that oil leaks can come from various parts of an engine, so diagnosing a rear main seal leak can be tricky. The telltale sign of a rear main seal oil leak is the location of the leak at the rear side of the engine, where it bolts up to the transmission.

If you suspect a rear main seal leak, there are a few temporary solutions you can try before opting for a costly repair. One option is to use an oil system additive, such as a rear main sealer, which is added directly to the engine's oil to repair gasket and seal leaks. Another option is to use a thicker engine oil, as thicker oil has a harder time getting through small cracks and can slow the rate of oil leaks. However, these are only temporary fixes, and in the long run, it is recommended to seek professional help to properly diagnose and address the issue.

Preserving Pan: Choosing the Right Size

You may want to see also

The oil pan gasket may be the source of the leak

There are several signs that you may be dealing with an oil pan gasket leak. Firstly, if you notice unexpected oil loss and your car's oil level is lower than expected, this could indicate a leak in the gasket under the oil pan. Secondly, an oil stain on the floor or driveway is another indicator of a probable oil pan leak. This means that motor oil has escaped from the engine and coated the surface where your car was parked. The size of the stain can sometimes indicate the severity of the leak. Thirdly, a burning oil smell may accompany an oil pan gasket leak. As the leak becomes worse, this odour typically gets stronger. The smell is caused by engine oil leaking out through the damaged gasket and contacting the hot exterior of the engine, causing it to burn and emit a strong odour.

Another sign of an oil pan gasket leak is engine oil coating the underside or undercarriage of the vehicle. A major leak can result in oil being blown backward along a moving vehicle's undercarriage due to the effects of blowback. As the severity of the breach increases, the oil will spread more widely. Finally, a low oil light in the instrument cluster may illuminate in the event of a considerable oil loss. This light often doesn't turn on until the oil level in the engine has dropped dangerously low. Therefore, it is important to stop driving and turn off the car as soon as this light comes on to prevent serious damage to the engine.

If you suspect an oil pan gasket leak, it is important to have it inspected and repaired by a qualified mechanic as soon as possible.

Pampered Chef Stoneware Bar Pan Sizing

You may want to see also

The input shaft seal could be worn and leaking

If you don't gap the oil pan to the bell housing, it can cause issues with the alignment of the engine. This can lead to strange loading on the crankshaft and input shaft. In some cases, it may also cause leaks. If you notice any leaks in your vehicle, it is important to identify the source of the leak and address it accordingly.

One possible cause of a leak in this situation could be a worn input shaft seal. The input shaft seal is located between the transmission and the engine, and it plays a crucial role in preventing fluid leaks. If the input shaft seal is worn, it can allow fluid to escape, leading to a leak.

To determine if the input shaft seal is the source of the leak, you should inspect the area for any signs of oil or fluid. If you find oil on the engine side of the flexplate or flywheel, it is likely that the input shaft seal is leaking. In this case, you may need to replace the seal or seek professional assistance.

It is important to note that there are other potential sources of leaks as well, such as the oil pan gasket, valve cover gasket, or distributor gasket. Therefore, it is recommended to thoroughly inspect the vehicle and identify the exact source of the leak before attempting any repairs.

By ensuring proper alignment between the oil pan and the bell housing, and addressing any leaks promptly, you can help maintain the performance and longevity of your vehicle.

Frozen Pizza: To Pan or Not?

You may want to see also

The oil pan bolts may need to be loosened and retightened

If the oil pan bolts are loose, it is likely that the oil pan gasket is leaking. This can be fixed by loosening the pan bolts, aligning the pan, and retightening the bolts.

Firstly, it is important to check that the oil pan bolts are, in fact, loose. This can be done by attempting to turn the bolts with a socket and ratchet. If the bolts can be turned, they are loose and need to be tightened.

If the oil pan bolts are loose, it is likely that the oil pan gasket is leaking. This can be fixed by loosening the pan bolts, aligning the pan, and retightening the bolts. To do this, first clean the bolt threads and the bolts themselves. Then, apply a thread locker, such as Loctite, to the bolts. Next, loosen the oil pan bolts and align the pan so that it is flush with the back of the block. This will ensure that the bellhousing is flush against the pan and the block for an easy bolt-together. Finally, retighten the oil pan bolts.

It is important to note that overtightening the oil pan bolts can distort the gasket and cause leaks. Therefore, it is recommended to only tighten the bolts to the specified torque, which is typically between 4 and 12 foot-pounds for Corvette C1 and C2 models. Additionally, it is worth noting that some oil pan bolts are designed to be tightened to a certain degree and then loosened, rather than simply tightened. These bolts are known as torque-to-yield bolts.

In some cases, the oil pan bolts may need to be replaced, especially if they are aluminium. Aluminium bolts are known to be flimsy and may not withstand multiple uses. If the oil pan bolts are replaced, it is recommended to use steel bolts, which are more durable.

By following these steps and ensuring that the oil pan bolts are properly tightened, you can help prevent leaks and keep your vehicle in good working condition.

Eradicating Burn Marks: Restoring Stainless Steel to its Former Glory

You may want to see also

The engine crankshaft and transmission input shaft may experience strange loading

The bellhousing to block and trans to bellhousing surfaces are precision-machined and have a tight flatness tolerance. This ensures that the engine crankshaft and transmission input shaft are perfectly in line. If the bellhousing is not sitting flat, it can affect the alignment and cause strange loading on the crankshaft and input shaft.

In some cases, shims or similar solutions may be suggested to fill the gap between the bellhousing and the oil pan. However, this is not recommended as a long-term solution as it does not address the underlying issue of improper alignment.

To correct this issue, it is recommended to loosen and retorque the pan bolts to ensure proper alignment and a secure fit between the bellhousing and the oil pan. This will help prevent potential damage to the crankshaft and input shaft due to strange loading.

By addressing the gap between the bellhousing and oil pan through proper bolt torquing and alignment, you can maintain the integrity of the engine and transmission components, ensuring their optimal performance and longevity.

Easy-Off: Pan Savior or Scourge?

You may want to see also

Frequently asked questions

If you don't gap the oil pan to the bellhousing, you may experience oil leaks, strange loading on the crankshaft and input shaft, and potential damage to the engine and transmission.

Check for oil spots on the ground or underneath the vehicle. You can also check the oil level and look for oil leaks around the engine, transmission, or other components.

It is recommended to identify the source of the leak and address it promptly. Minor leaks can be temporarily addressed with products like BlueDevil Oil Stop Leak, but more severe leaks may require replacing seals, gaskets, or other components.