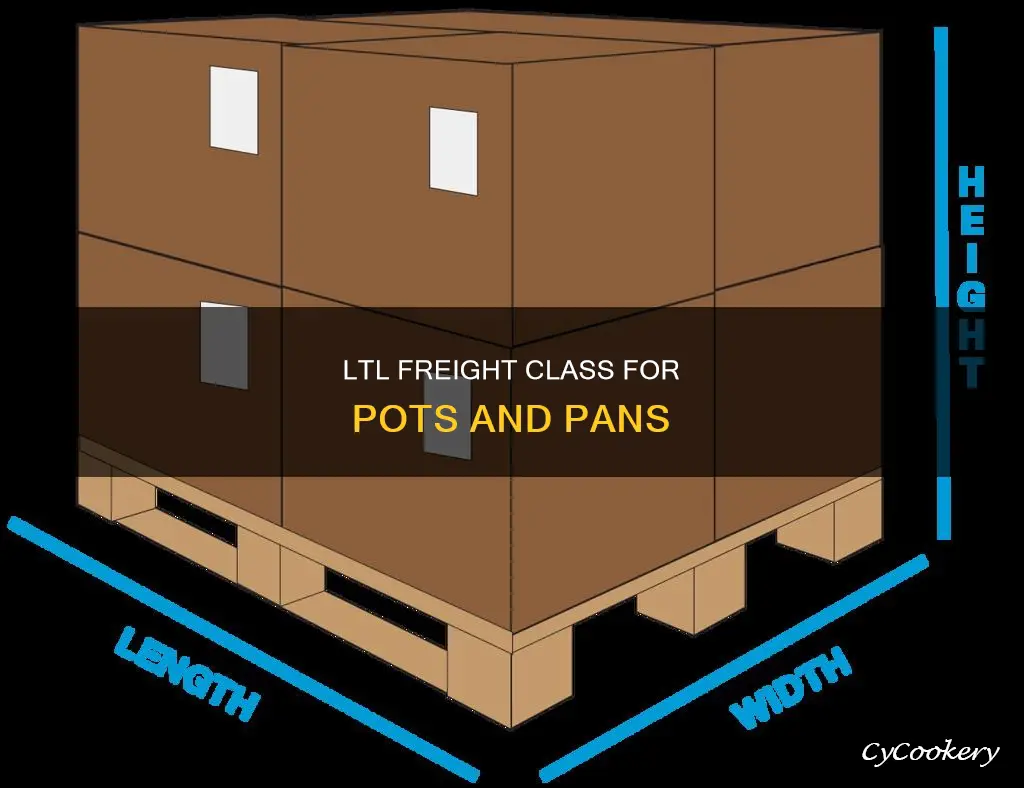

Less-than-truckload (LTL) shipping is a cost-effective method of freight transportation that allows multiple businesses to share trailer space. LTL freight classes are a standardised method of defining the price of LTL freight based on the ease of movement. The National Motor Freight Traffic Association (NMFTA) defines a class as a way to establish a commodity's transportability. The National Motor Freight Classification (NMFC) is the standard that enforces this system, grouping commodities into one of 18 classes, ranging from 50 to 500. Class 50 is the cheapest to ship, while class 500 is the most expensive.

The LTL freight class for pots and pans will depend on several factors, including density, stowability, handling, and liability. Density is the relationship between the weight of a shipment and the space it occupies. Stowability refers to how easily a shipment can be arranged with other freight in the transport vehicle. Handling considers the item's ability to be handled as freight is loaded and unloaded from terminal to terminal. Liability takes into account the probability of the shipment being damaged or stolen, or damaging other adjacent freight.

| Characteristics | Values |

|---|---|

| Definition | A way to "establish a commodity's transportability" |

| Determination | Density, stowability, handling, and liability |

| Density | Pounds per cubic feet |

| Handling | Ease of movement between LTL terminals, considering fragility and packaging |

| Stowability | How the shipment can be arranged with other freight in the transport vehicle |

| Liability | Probability of the shipment being lost, stolen, damaged, or damaging other freight |

| Weight range | 50-500 |

| Weight range per cubic foot | Non-alcoholic beverages, dry soups, dense snacks, small household appliances, stuffed furniture, standard potato chips, wood cabinets, tables |

What You'll Learn

Density: weight per cubic foot

Density is a key factor in determining the freight class of a shipment. It is defined as the weight of a shipment in relation to the space it occupies, or the pounds per cubic foot. A higher density typically results in a lower freight class, while lower density commodities result in a higher freight class. This is because carriers can maximize trailer capacity when handling denser items.

To calculate the density of a shipment, one must divide the weight of the items in pounds by their volume in cubic feet. To find the volume of the items in cubic feet, one would multiply the length by width by height. For example, an item that weighs 50 pounds per cubic foot would fall under class 50, whereas an item that weighs 1 pound per cubic foot would fall under class 500.

It is important to note that not all items are classified solely based on density. Some commodities, such as vehicle transmissions, have a fixed class regardless of size or weight. Additionally, the National Motor Freight Traffic Association (NMFT) may change classifications in response to fluctuating markets, which can impact shipping costs.

When determining the freight class of a shipment, it is crucial to consider all relevant factors, including density, handling, stowability, and liability. By providing accurate information and following the tips outlined in this guide, shippers can optimize their shipping process and avoid potential delays and additional costs.

Deep Dish Pizza Pans: Reviews and Buying Guide

You may want to see also

Handling: ease of movement between terminals

When determining the LTL freight class for pots and pans, handling is a key consideration. Handling refers to the ease of moving a product between LTL terminals, taking into account factors such as fragility and packaging.

Pots and pans can vary significantly in terms of their size, weight, and materials used, which will impact their fragility and packaging requirements. For example, a large, heavy-duty cast iron pot will likely be more fragile and require different packaging than a lightweight, non-stick pan. Therefore, when determining the LTL freight class for pots and pans, it is important to consider the specific characteristics of the items being shipped.

To ensure efficient handling between terminals, pots and pans should be packaged securely and in a way that optimises space. This may involve using specialised packaging materials such as bubble wrap, foam, or cardboard dividers to protect the items from damage during transit. Additionally, pots and pans can be stacked or nested to maximise space utilisation, reducing the number of packages and pallets required.

Another important factor to consider is whether the pots and pans require any special handling instructions. For example, if the items are particularly fragile or valuable, they may need to be handled with extra care, which could impact the ease of movement between terminals. Special handling instructions may also be necessary if the pots and pans are part of a larger shipment that includes hazardous materials or items with unusual dimensions.

Overall, the ease of movement between terminals for pots and pans will depend on a combination of factors, including their size, weight, fragility, packaging, and any special handling requirements. By optimising these factors, shippers can ensure that their pots and pans are handled efficiently and effectively between LTL terminals.

Paella Pan Size for Four

You may want to see also

Stowability: how freight is arranged with other goods

Stowability is one of the four characteristics used to determine a product's freight class. The others are density, handling, and liability. Stowability refers to how the dimensions (size and shape) of the goods being shipped fit into the container facilitating the shipment. It also takes into account how the shipment can be arranged with other freight in the transport vehicle.

Stowability is one of the seven major categories that affect the economics of transportation services. It plays a key role in how the rate class will be determined, which affects the total cost of shipping a particular good. The greater the stowability, the lower the freight class.

Some items have low stowability because they cannot be stowed together. For example, hazardous materials must be transported according to specific safety policies and regulations. Some freight also cannot bear an additional load and, therefore, cannot be stacked.

Other items have low stowability because they have excessive weight, length, or oddly shaped protrusions that make them impossible to load with other freight. For example, imagine an oddly shaped object with lots of space around it during transport. This object has low stowability.

On the other hand, items with high stowability can be placed alongside other similarly shaped objects. For instance, a regularly shaped object on a pallet that can be placed alongside other regularly shaped objects has high stowability.

Grease Pan Disaster: Quick Fix

You may want to see also

Liability: probability of damage or theft

When it comes to liability in the context of LTL freight classes, it pertains to the probability of damage or theft. This is one of the key factors that determine the freight class of a shipment, as defined by the National Motor Freight Traffic Association (NMFTA) and enforced by the National Motor Freight Classification (NMFC).

Liability is a crucial aspect that carriers consider when determining the potential risks associated with transporting a particular type of cargo. The higher the likelihood of damage or theft, the higher the freight class will be. This is because a higher freight class often translates to higher shipping costs, as carriers need to account for potential losses or additional security measures.

For example, perishable cargo or cargo prone to spontaneous combustion or explosion will typically fall into a higher freight class due to the increased risk of damage or theft. These types of shipments may require specialised handling, temperature control, or enhanced security measures, all of which impact the overall cost of transportation.

Additionally, the liability factor also considers the potential for the cargo to cause damage to adjacent freight. For instance, if a shipment is particularly fragile or prone to leaking, it may be assigned a higher freight class to account for the possibility of it damaging other cargo during transport.

To mitigate the risks associated with liability, carriers often implement various strategies. These can include obtaining cargo liability insurance, which protects them from being held financially responsible for loss or damage to the cargo. Proper documentation and thorough inspections at various stages of the shipping process are also essential to establish the condition of the cargo and assign responsibility in case of damage or theft.

Furthermore, carriers may employ specific security measures to deter theft, especially for high-value or attractive cargo. This can include the use of security tags, regular checks during stops, and parking in secure and well-lit areas. By taking these proactive measures, carriers can reduce the likelihood of theft and minimise their potential losses.

In summary, liability in the context of LTL freight classes is a critical factor that helps carriers assess the potential risks and costs associated with transporting a particular type of cargo. By considering the probability of damage or theft, carriers can make informed decisions about pricing, handling, and security measures to ensure the safe and efficient transportation of goods.

Baking Pan Grease: Butter, Oil, or Spray?

You may want to see also

Weight and dimensions: how they affect class

Weight and dimensions are key factors in determining the freight class of pots and pans. The National Motor Freight Traffic Association (NMFTA) defines a class as a way "to establish a commodity's transportability". The National Motor Freight Classification (NMFC) is the standard that enforces this system, grouping commodities into one of 18 classes, ranging from 50 to 500.

The weight and dimensions of a shipment play a crucial role in determining its density, which is a significant factor in assigning a freight class. Density is calculated by dividing the weight of the items in pounds by their volume in cubic feet. Higher density typically corresponds to a lower freight class, resulting in lower shipping costs. This is because carriers prefer shipping items that are heavy but don't occupy much space.

In addition to density, stowability, or how efficiently items can be arranged with other freight in the transport vehicle, is another important consideration. Items with irregular dimensions or those that need to be shipped separately, such as hazardous materials, may be assigned a higher freight class due to the difficulty in maximising space utilisation.

The weight and dimensions of pots and pans can also impact their handling, which is another factor in determining freight class. Items that are bulky, heavy, or fragile may require special attention during loading and unloading, resulting in a higher freight class.

Furthermore, weight and dimensions can influence liability, the fourth factor in determining freight class. Items that are more likely to be damaged or stolen, or that pose a risk to adjacent freight, are assigned a higher liability rating, leading to a higher freight class.

Overall, the weight and dimensions of pots and pans play a crucial role in determining their freight class by affecting their density, stowability, handling, and liability. Accurate measurement and honest declaration of these factors are essential to ensure smooth shipping processes and avoid unnecessary costs.

Pricing Pots and Pans for Yard Sales

You may want to see also

Frequently asked questions

LTL stands for Less Than Truckload. It is a shipping method where you only pay for the space your freight takes up in a trailer, as opposed to moving a full truckload of freight (known as Truckload or TL shipping).

The LTL freight class of pots and pans is determined by four characteristics: density, stowability, handling, and liability. Density is defined as the pounds per cubic feet of your shipment. Stowability refers to how the shipment can be arranged with other freight in the transport vehicle. Handling concerns the item's ability to be handled as the freight is loaded and unloaded from LTL terminal to LTL terminal. Liability takes into account the probability of the shipment being damaged or stolen, or damaging other adjacent freight.

LTL freight shipping offers cost savings for shippers with smaller loads. It is also flexible and adaptable to various commodity sizes.

You can use a freight class calculator to determine the density and estimated class of pots and pans. However, keep in mind that these tools offer only "estimated" classes. To ensure accuracy, confirm your freight class using the correct National Motor Freight Classification (NMFC) code, and make sure it is visible and legible on the freight bill of lading (BOL) used at the time of pickup.