The oil pump is an essential component of an engine's lubrication system, which is critical to its operation. The pump draws oil from the oil pan (also known as the sump or oil tray) and forces it through oilways in the engine, providing lubrication and cooling to the moving parts. This process is known as a forced-feed lubrication system. The oil pump's location in the oil pan ensures a consistent supply of oil, and its failure can lead to catastrophic engine damage. The oil is then filtered to remove debris and circulated through the engine, where it reduces friction and heat before returning to the oil pan to be recirculated.

| Characteristics | Values |

|---|---|

| Oil pump type | Positive displacement pump |

| Oil pump location | Oil pan/front of the engine |

| Oil pump function | Circulates engine oil under pressure to rotating bearings, sliding pistons, and the camshaft of the engine |

| Oil pump pressure | 1-60 lbs./in2 |

| Oil filter function | Removes foreign bodies from the oil |

| Oil sump/pan function | Oil reservoir, allows oil to settle and be cooled |

| Oil sump/pan location | Bottom of the engine |

| Oil sump/pan capacity | 4-6 quarts |

What You'll Learn

Oil pump failure leads to engine failure

The oil pump is an integral part of an engine's performance. It sucks oil from the oil pan and pumps it through the oil filter onto the bearings. The pump pressurises the oil system, ensuring oil is distributed around the engine to lubricate its components.

If the oil pump fails, the engine will quickly get damaged. A worn or failing pump will cause a loss of oil pressure, starving the engine of oil. This will cause the internal components, such as bearings, camshafts, and crankshafts, to make contact with each other, resulting in extensive and expensive damage.

The first symptom of a failing oil pump is usually the engine or oil light indicator on the dashboard. Other symptoms include low oil pressure, increased engine temperature, and noise. If the oil pressure gets too low, the vehicle won't start.

If the oil pump fails, the engine will need to be either rebuilt or replaced. Therefore, it is important to get the pump diagnosed by a professional as soon as possible to prevent further damage to the engine.

The Lead Concern: Are Old Cast Iron Pans Safe?

You may want to see also

Oil pump location

The oil pump is an essential component of an internal combustion engine, delivering and maintaining the flow of engine oil to various parts. It is usually located inside the engine, at the bottom, or mounted externally.

The oil pump is typically found inside the engine, submerged or around the level of oil in the sump (oil pan). It is mounted low down to avoid the need for priming. In some engines, the pump may be located inside the crankcase or in the lower part of the engine, below or to the side of the crankshaft.

Externally Mounted Oil Pumps

In some cases, the oil pump may be fitted to the outside of the engine, usually at the front cover, and turned by the crankshaft. These externally mounted pumps often have the oil filter attached to the pump body.

The location of the oil pump can vary depending on the type of engine and its specific design. For example, in dry sump engines, there are at least two oil pumps: one to pressurize and distribute oil, and at least one "scavenge pump" to evacuate pooled oil from the bottom of the engine. The scavenge pump may or may not be located in the sump.

The Ultimate Guide to Sterilizing Your Cast Iron Pan

You may want to see also

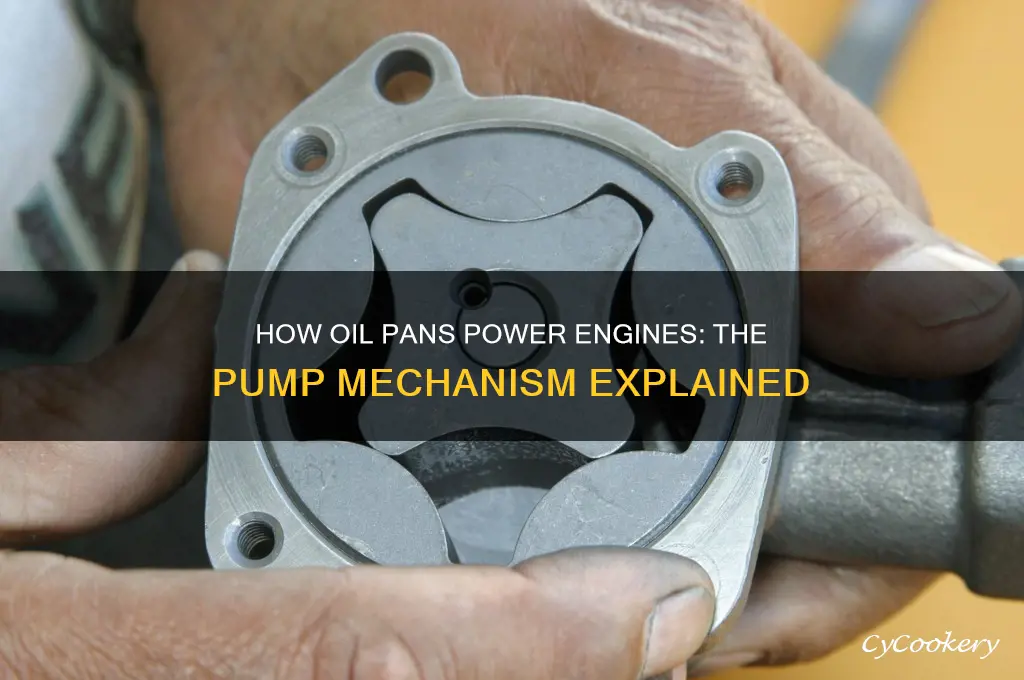

Oil pump types

The oil pump is an essential component of an internal combustion engine, responsible for circulating engine oil under pressure to vital components such as rotating bearings, sliding pistons, and the camshaft. There are several types of oil pumps available, each with its own unique design and functionality. Here is an overview of some common oil pump types:

- Gear Pumps: Gear pumps are one of the most commonly used oil pump types. They utilise a set of special gears to draw in oil at low pressure and increase its pressure by squeezing it through a chamber. This design is simple and reliable, making it a popular choice for many engines.

- Trochoid Pumps: Trochoid pumps, also known as gerotor pumps, are another type of positive displacement pump. They use an inner and outer rotor to create a pumping action, providing smooth and continuous oil flow.

- Vane Pumps: These pumps use a rotating rotor with sliding vanes to create a pumping action. While vane pumps can provide high flow rates and pressures, they are less common due to modern manufacturing techniques that favour other pump designs.

- Plunger Pumps: Plunger pumps were used in the past for small engines but have now been largely replaced by other pump types. They use a reciprocating plunger to create pressure and are typically only found in rare cases.

- Paddle Wheel Pumps: Paddle wheel pumps are an upgrade to traditional gear pumps, offering faster instantaneous reaction times and higher flow rates. They are designed to address issues with oil returning back down the intake tube, ensuring consistent oil pressure.

It is important to select the right type of oil pump for your specific engine application to ensure optimal performance and lubrication. Different engines may have unique requirements, such as higher flow rates or the need to maintain pressure at higher engine speeds. By choosing the appropriate oil pump, oil pan, windage tray, and pickup tube, you can effectively eliminate many oiling-related issues.

Toasting Bread in a Pan: Soggy Surprises and Solutions

You may want to see also

Oil pressure

The oil pressure is created by a fluid flow restriction in the outlet line of the pump and is measured in pounds per square inch (PSI). It typically varies depending on the engine type, design, and oil viscosity. It is important to maintain the manufacturer's recommended oil pressure levels to ensure the longevity of the engine.

Most engines should generate about 10 psi for every 1000 revolutions per minute (rpm), peaking around 55-65 psi. Oil pressure is higher when the engine is cold due to the increased viscosity of the oil, and it decreases as the engine warms up. It then increases with engine speed until the relief valve in the oil pump opens to divert excess flow. Oil pressure is lowest when the engine is idling and hot.

Maintaining the correct oil pressure is crucial for the smooth operation and longevity of your vehicle. Low oil pressure can lead to increased friction, causing unusual noises such as knocks, ticking, or whining sounds. It may also result in poor engine performance, including reduced power, poor acceleration, and rough idling. In addition, insufficient oil pressure can lead to higher engine temperatures and even overheating. Therefore, it is important to address low oil pressure issues promptly to prevent severe engine damage.

To fix low oil pressure, you should start by verifying the engine oil level and topping it up if necessary. Other steps include replacing the oil filter, inspecting and replacing the oil pump if needed, and ensuring regular oil changes and the use of the correct type of oil.

Navigating to the Robert F. Panara Theatre: A Guide

You may want to see also

Oil sump/oil pan design

The oil sump, also known as the oil pan, oil tray, or oil reservoir, is an essential component of a lubrication oil system in both four-stroke and two-stroke internal combustion engines. The design of the oil sump plays a crucial role in the performance of the oiling system, and a poorly designed pan can lead to engine damage.

There are two main types of oil sump designs: dry sump and wet sump. Dry sump systems have multiple sumps per engine, with a primary and secondary sump. Oil drains from the engine into the main sump, and then it is removed to an additional external sump. This design ensures that only a small amount of oil accumulates within the main sump. Dry sumps are more complex as they require additional piping and pumps. They are often used in racing applications as they reduce oil sloshing and improve power. On the other hand, wet sump systems are simpler and form part of the main engine crankcase. They do not have a separate sump, but they require more space under the engine for oil storage. Wet sumps typically use baffles to prevent oil splashing during acceleration or travelling up an incline.

When designing an oil sump, it is important to consider the environment in which the engine will operate. Factors such as hard acceleration, heavy braking, and cornering can impact the performance of the oiling system. A well-designed oil pan should have features like trap doors, baffles, windage trays, and crank scrapers to ensure that oil is retained in the sump where the pickup tube is located. The pickup tube assembly should be designed to keep as much oil as possible in the sump. Additionally, the oil pan should have a screen to prevent large pieces of debris from entering the oil pump.

The oil sump also plays a role in cooling the oil. Cooling fins on the sump increase the surface area in contact with the surrounding air, enhancing heat transfer. As the vehicle accelerates, more air passes over the oil sump, providing increased cooling as the engine oil temperature rises. However, for larger engines, a separate system for cooling lubrication oil is necessary.

In conclusion, the design of the oil sump is critical to the effective lubrication and cooling of an engine. The choice between a dry sump and a wet sump system depends on various factors, including the intended use of the vehicle and the available space. A well-designed oil sump ensures the efficient delivery of oil to the engine, preventing damage and optimizing performance.

Roasting Pan Size for 12-Pound Turkey

You may want to see also

Frequently asked questions

An oil pump is a critical part of an engine's lubrication system. It draws oil from the oil pan (or oil sump) and forces it through oilways in the engine, ensuring that all moving parts are lubricated and cooled.

Oil pumps use a set of special gears to take in oil at low pressure and squeeze it to high pressure. The oil then passes through a chamber with a spring-loaded valve, which opens when the oil pressure reaches a certain level, allowing oil to flow out and circulate through the engine.

Oil pumps are usually situated at the front of the engine, but they can also be located inside the oil pan or crankcase.

A wet sump system is simpler and more common, forming part of the main engine crankcase. In contrast, a dry sump system has a separate, external sump, and requires additional pumps to evacuate the oil that pools at the bottom of the engine.

The frequency of oil changes depends on various factors, including the type of car, driving conditions, and age of the vehicle. As a general guideline, most newer cars can go between 3,000 to 5,000 miles before needing an oil change.