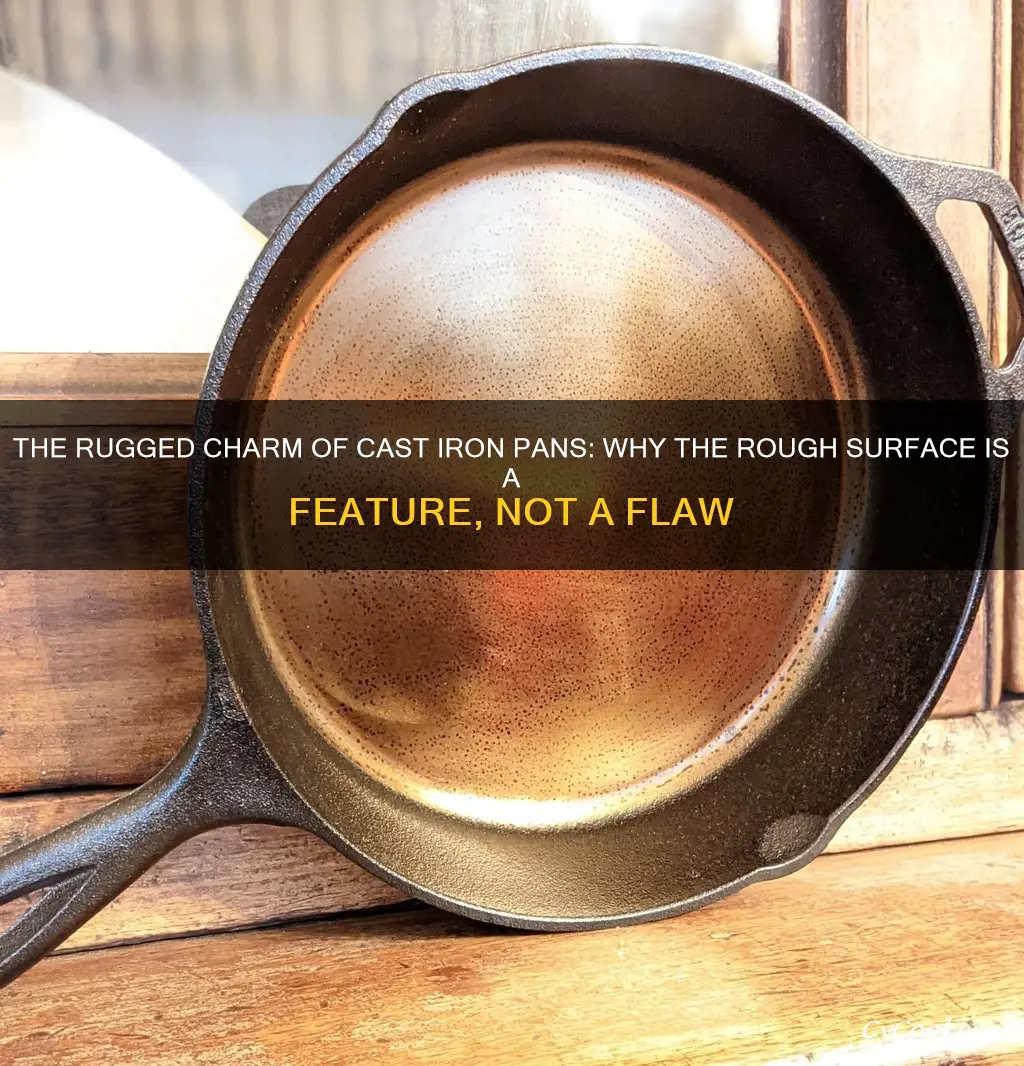

Cast iron pans are a kitchen staple, but why are they so rough? The answer lies in the manufacturing process. Modern cast iron pans are made by machines, taking only 90 minutes to produce. The iron/steel mixture is melted and poured into moulds made of sand, clay powder, and water. The cast iron is then tumbled to remove excess sand, a process that gives it its distinctive rough texture. This method of production is much faster and more cost-effective than the traditional hand-poured method, which could take up to three days. While some people prefer the smooth finish of vintage cast iron pans, others find the rough texture of modern pans easier to season and maintain. Ultimately, the choice between a smooth or rough cast iron pan comes down to personal preference, as both types can be well-seasoned and used to create delicious meals.

What You'll Learn

Manufacturing methods have changed

In the past, cast iron pans were made by hand. Ironworkers would melt down iron and scrap steel and pour the mixture into a mould. This process allowed for more intricate designs and resulted in pans that were several pounds lighter than their modern counterparts. The pans were then ground down using stone, giving them a super-smooth, satin-like finish. The entire process took at least three days.

Today, cast iron cookware is made by machines in approximately 90 minutes. After the iron/steel mixture is melted, it is poured into moulds made of sand, powdered clay, and water. The cast iron is then tumbled to remove any extra sand from the mould by machine. Manufacturers have cut out the polishing step, which has helped keep prices competitive. The pans are not ground smooth like their predecessors, resulting in a pebbly, rough finish.

Dennis Powell Jr., a cast-iron expert and founder of Butter Pat Industries, a cast-iron cookware company, attributes the evolution of cast iron to the switch from a smooth-finished surface to a pre-seasoned, much rougher one. According to Powell, until the 1950s, every cast-iron pan sold in America was created without pre-seasoning. Lodge started selling their pans pre-seasoned because they knew that people no longer wanted to do the seasoning themselves.

The entire concept of seasoning cast iron was a result of the new, rougher surface. The roughness that you feel on most modern cast iron is sand, which used to be removed during production. However, that step has been eliminated by most contemporary manufacturers. "A lot of cast iron today is produced in 90 minutes," says Powell, whereas "at the turn of the 20th century, cast iron would sit in moulds for upwards of 48 hours before then being tumbled for 24 hours," resulting in a smooth finish.

Pots and Pans: Choosing the Best

You may want to see also

Sand used to be removed during production

Cast iron pans used to be polished smooth, but the newer ones aren't. The roughness that you feel on most modern cast iron is sand, which used to be removed during production. However, that step has since been eliminated by the majority of contemporary manufacturers.

The entire process of making vintage cast iron took at least 3 days. The cast iron would sit in moulds for up to 48 hours and then be tumbled for 24 hours. As a result, vintage cast iron was incredibly smooth.

New cast iron cookware is made by machines in approximately 90 minutes. After the iron/steel mixture is melted, it is poured into moulds made of sand, powdered clay, and water. The cast iron is then tumbled to remove any extra sand from the mould by machine.

Part of the reason why these pans are made so quickly is that the manufacturers have cut out the polishing step in the process. These pans are not ground smooth like their predecessors. Dropping this step helped to keep pricing competitive. They have a pebbly, rough finish and are dark grey in colour. They are also usually pre-seasoned in the factory shortly after they are made.

The Truth About Enamel-Coated Cast Iron: Leaching Iron or Not?

You may want to see also

The polishing step has been cut

Originally, cast iron pans were made by hand. Iron and scrap steel were melted down and then poured by an ironworker into a mould. The resulting pan was then ground down, or milled, using stone. These pans were sold unseasoned to the consumer. They had a super-smooth, satin-like finish that appears a little darker due to the extra light reflection.

Now, the manufacturing process is much quicker. After the iron/steel mixture is melted, it is poured into moulds made of sand, powdered clay, and water. The cast iron is then tumbled to remove any extra sand from the mould by machine. The polishing step has been cut from this process. These pans are not ground smooth like their predecessors. They have a pebbly, rough finish and are dark grey in colour. They are also usually pre-seasoned in the factory shortly after they are made.

Dennis Powell Jr., the founder of cast-iron cookware company Butter Pat Industries, attributes the entire evolution of cast iron to the switch from a smooth-finished surface to a pre-seasoned, much rougher one. He states that the roughness that you feel on most modern cast iron is sand, which used to be removed during production.

Disposable Loaf Pan Mix Quantity

You may want to see also

Rough surfaces help seasoning oils to adhere

The rough surface of modern cast iron pans is the result of a change in manufacturing methods. In the past, cast iron pans were polished to achieve a smooth finish, but this step has since been eliminated to reduce costs and production time. According to some manufacturers, the rough surface of modern cast iron pans helps seasoning oils to adhere better than a smooth finish. The pebbly, rough finish of modern cast iron pans is created by pouring the iron/steel mixture into moulds made of sand, powdered clay, and water, and then tumbling the cast iron to remove any extra sand. This process takes approximately 90 minutes, whereas the traditional method of creating a smooth finish on cast iron pans took at least 3 days.

The entire concept of seasoning cast iron is a result of the switch to a rougher surface. Seasoning acts as a levelling agent to prevent proteins from adhering to the pan. While some people believe that a smooth surface is more non-stick than a rough one, others argue that the rough surface is easier to season. It is worth noting that both types of pans can be well-seasoned, and the debate ultimately comes down to personal preference.

Some people prefer the smooth surface of vintage cast iron pans for their non-stick properties. The smooth finish was achieved by grinding or milling the pan using stone, resulting in a super smooth, satin-like finish. However, this step was time-consuming and labour-intensive, contributing to the higher cost of vintage cast iron pans.

Maintaining a smooth finish on a cast iron pan requires regular polishing, which can be done using an electric hand sander or by hand with sandpaper. Polishing helps to remove any built-up seasoning and creates a mirrored finish. However, it is important to be cautious when polishing to avoid thinning out the pan unevenly, which can lead to cracking and create an uneven cooking surface.

In conclusion, the rough surface of modern cast iron pans is a result of changes in manufacturing methods and has led to the concept of seasoning cast iron. While some people prefer the smooth surface of vintage pans, others find the rough surface easier to season and maintain. Ultimately, the debate between smooth and rough surfaces comes down to personal preference, as both types of pans can be effectively seasoned and used for cooking.

Patty Pan Squash: Pot-to-Plate

You may want to see also

Rough cast iron is easier to season

The rough texture of modern cast iron pans is a result of the sand casting process used during manufacturing. This texture is said to help the seasoning oils to adhere better to the pan than a smooth finish would. The entire concept of seasoning cast iron acts as a levelling agent so that proteins won't adhere to the pan.

The process of seasoning involves baking oil onto the cast iron through polymerization, creating a natural, easy-release cooking surface. This process is much simpler than many imagine. After washing and drying your pan, you rub it all over with cooking oil and buff it thoroughly. The pan is then heated in the oven, where the oil polymerizes and forms a protective coating. This process is repeated 3 to 4 times to set down a good initial layer of seasoning.

Fans of modern cast iron pans claim that the rougher, pebbly surface is easier to season. This is because there are more tiny indents for the oil to adhere to. However, some people prefer the smooth surface of vintage cast iron pans for their non-stick properties. Ultimately, it comes down to personal preference, as both types of pans can be well-seasoned.

Rock Pans: Safe or Not?

You may want to see also

Frequently asked questions

Modern cast iron pans are made by machines in approximately 90 minutes. The iron/steel mixture is poured into moulds made of sand, powdered clay, and water. The cast iron is then tumbled to remove any extra sand from the mould by machine. The polishing step has been cut out of the manufacturing process to keep pricing competitive.

From the late 1800s to the mid-1900s, cast iron was made by hand. The pans were ground down, or milled, using stone, resulting in a super smooth, satin-like finish. The entire process of making a cast iron pan took at least 3 days.

Rough cast iron pans are easier to season. According to some manufacturers, the rough surface helps seasoning oils to adhere better than a smooth finish.

Old-fashioned purists believe that the smooth surface of a vintage piece is the ultimate choice for its non-stick properties. Some also believe that building a good seasoning on a smooth surface is more difficult, as there are fewer tiny indents for the oil to adhere to.