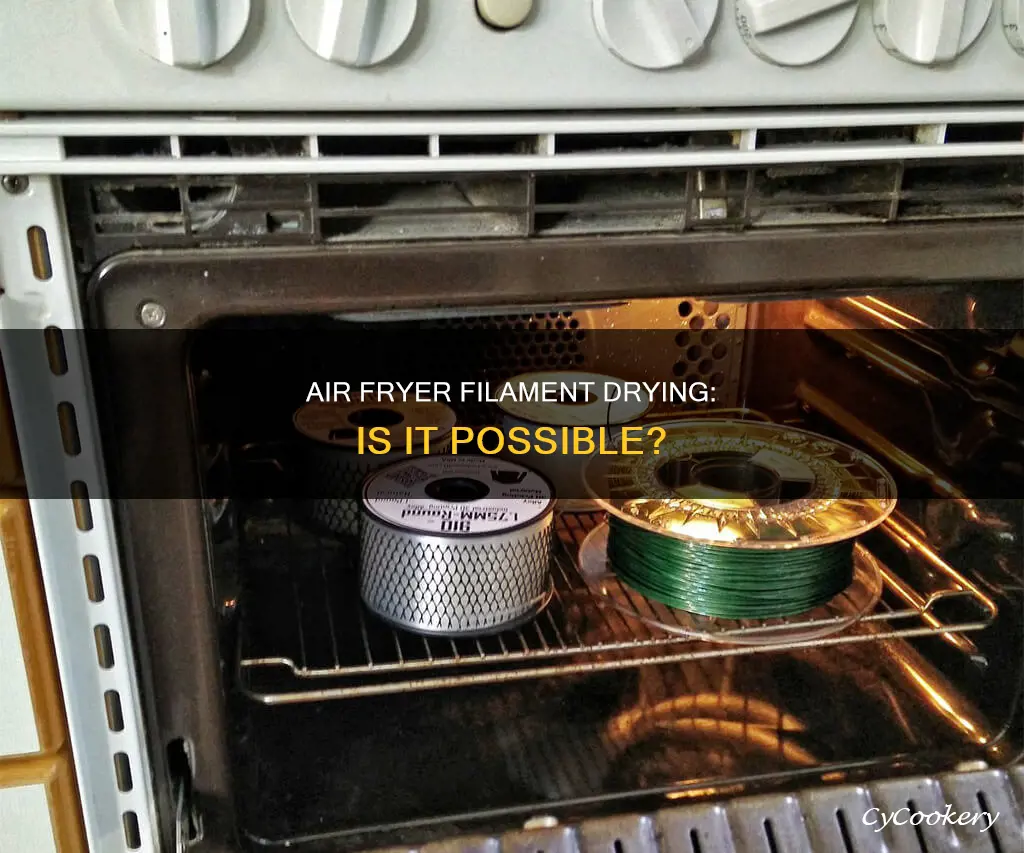

Whether you can dry filament in an air fryer is a question that has been asked by many people, especially those who are interested in 3D printing. The answer depends on the temperature settings of the air fryer and the type of filament. Some people have reported success in drying filament in their air fryers, while others have found that the air fryer does not get hot enough to dry the filament effectively. It is important to note that the filament must be dried at a temperature below its glass transition temperature to avoid damaging it. Additionally, some sources suggest that air fryers may not be ideal for drying filament because they recirculate the air, which can lead to the filament reabsorbing moisture. As such, other appliances such as food dehydrators or ovens may be more effective for drying filament.

| Characteristics | Values |

|---|---|

| Can you dry filament in an air fryer? | Yes, but it is not recommended. |

| Best way to dry filament | Using a dedicated filament dryer, a food dehydrator, or an oven. |

| Why is drying filament important? | Moisture buildup can occur due to the properties of the filament being used, and can cause defective prints. |

| How to prevent moisture buildup | Filaments can be stored in Ziploc bags with dehydrating agents like silica gel or vacuum-sealed. |

| Recommended drying temperature | Below the material's melting point and glass transition temperature (Tg). |

| Safety tips | Use efficient ventilation and a heat-resistant spool to prevent warping or melting. |

What You'll Learn

- Air fryers may not be suitable for drying filament due to their small size

- The minimum temperature required to dry filament is debated

- Some people have successfully dried filament in their air fryers

- Freezers can be used to dry filament

- A food dehydrator is recommended over an air fryer for drying filament

Air fryers may not be suitable for drying filament due to their small size

The size of an air fryer can also be a limiting factor when trying to dry larger spools of filament, as they may not fit into the appliance. Additionally, air fryers recirculate the air inside, which can quickly saturate the environment. Once the air is saturated, the moisture can re-enter the filament as much as it escapes, making it challenging to achieve effective drying.

Instead of using an air fryer, a food dehydrator or a conventional oven can be a better option for drying filament. Food dehydrators are designed to slowly remove excess moisture by providing low heat, allowing the filament to dry thoroughly. Ovens, on the other hand, can be set to low temperatures, and by using a wooden spoon to keep the door slightly ajar, similar to the process of making beef jerky, you can create a suitable environment for drying filament.

It is important to note that drying filament requires maintaining temperatures below the glass transition temperature (Tg) of the specific filament material. Exceeding this temperature can cause the filament to become brittle or glassy, impacting its performance during 3D printing. Therefore, it is crucial to refer to the technical datasheets of the filament to determine the appropriate drying temperature.

Additionally, as filaments emit harmful fumes when heated, it is recommended to use dedicated appliances for drying filament that are separate from those used for cooking food. Proper ventilation is also essential during the drying process to manage the harmful fumes and unpleasant smells that may be produced.

Dehydrating Okra in an Air Fryer: A Step-by-Step Guide

You may want to see also

The minimum temperature required to dry filament is debated

It is important to note that drying filament at too high a temperature can cause the material to crystallize and become glassy when it cools, making it less pliant when fed into 3D printers. Therefore, it is crucial to stay below the filament's melting point and glass transition temperature during the drying process.

Additionally, the method of drying can also impact the minimum temperature required. For example, one source mentions that air fryers recirculate the air, quickly saturating the environment and leading to moisture re-entering the filament. In contrast, food dehydrators provide a constant supply of dry air, allowing the filament to dry at lower temperatures (50-60°C) as long as the air is constantly changing.

Overall, while there is some debate over the minimum temperature required to dry filament, it is clear that staying below the glass transition temperature is crucial to prevent damage to the filament. The specific temperature settings will depend on the type of filament and the drying method being used.

Air Fryer Potato Tots: Quick, Crispy, Golden Treats

You may want to see also

Some people have successfully dried filament in their air fryers

One user on Reddit reported that they had successfully dried filament in their air fryer, but another user cautioned that the temperature settings on air fryers may not go low enough to safely dry filament. The ideal temperature for drying filament is around 40°C to 60°C, and some air fryers may not be able to reach or maintain this temperature range.

Additionally, some air fryers may have a "dehydrate" setting that can be used for drying filament. For example, the Ninja Air Fryer has a dehydrate setting that defaults to 60°C but can be adjusted down to 40°C. This particular air fryer has been used successfully by some individuals to dry filament.

Another user on a different forum shared their experience of using an air fryer to dry filament. They mentioned that they had to experiment with different temperatures and times, but were eventually able to find a setting that worked for them. They also emphasized the importance of staying below the glass transition temperature of the filament to avoid overheating and over-hydration, which can lead to brittleness.

It is worth noting that while some people have had success with using air fryers for drying filament, others have encountered challenges. One user reported that their filament became more brittle after attempting to dry it in an air fryer, even though they used the "dehydrate" setting for 45 minutes.

In conclusion, while it is possible to dry filament in an air fryer, it is important to exercise caution and monitor the temperature closely to avoid damaging the filament. Each air fryer model is different, so it is essential to understand the capabilities and limitations of your specific device before attempting to dry filament.

Air Fryer: Perfectly Stuffed, Every Time

You may want to see also

Freezers can be used to dry filament

Another factor to consider is the temperature of the freezer. While freezers typically have very low temperatures, it is important to ensure that the temperature does not drop below the glass transition temperature (Tg) of the filament. The Tg values can be found on technical datasheets of polymers or through an online search. Maintaining the temperature above Tg is crucial to prevent the filament from becoming brittle or experiencing other negative effects.

Additionally, it is important to control the thawing process carefully. The filament should be allowed to warm up slowly while still sealed inside the bag, ensuring that any condensation occurs outside the bag. This gradual process helps prevent moisture from being re-absorbed into the filament.

It is worth noting that using a freezer for drying filament may not be the most practical or energy-efficient solution for everyone. Other methods, such as using a dedicated filament dryer, a food dehydrator, or an oven set to a low temperature, can also be effective in removing moisture from the filament. These methods may be more convenient and accessible for those without access to a freezer or looking for a quicker solution.

Overall, while freezers can be used to dry filament, it is important to carefully manage the sealing, temperature, and thawing process to ensure the best results and avoid any potential issues.

Air-Fried Karaage: Crispy Chicken Delight

You may want to see also

A food dehydrator is recommended over an air fryer for drying filament

While it is possible to dry filament in an air fryer, it is not recommended. The compact interior of an air fryer would place the filament much closer to the heating element than in an oven, which could result in uneven drying or overheating. For this reason, a food dehydrator is a better option for drying filament.

Food dehydrators are designed to slowly remove excess moisture by providing low heat, allowing the items placed inside to last longer. Dehydrators use low-temperature dry air for the drying process, and very few small kitchen appliances can hold a low temperature for the amount of time required for dehydration.

Air fryers, on the other hand, use hot air to cook foods at high temperatures without oil. The heat source is usually a fan blowing heated air through a metal basket inside the appliance. Air fryers are great for cooking vegetables and meats, and for baking bread or cookies, because they don't require any oil.

Air fryers are also limited in terms of capacity. Even the largest air fryers may not have enough capacity to feed a large family. Air fryers are best used for families of four or fewer.

In addition, air fryers can sometimes cook food unevenly, resulting in some parts being undercooked and others overcooked. Food dehydrators, on the other hand, allow you to dry out fresh fruits and vegetables without losing any nutrients and require very little to no interaction during the cooking process.

Therefore, while it is technically possible to dry filament in an air fryer, a food dehydrator is a much better option due to its ability to maintain low temperatures for extended periods of time, its larger capacity, and its even drying capabilities.

Air-Fryer Roasted Peanuts: Timing for Crunchy Nuts

You may want to see also

Frequently asked questions

Yes, you can dry filament in an air fryer, but it is not recommended. The compact interior of an air fryer places the filament a lot closer to the heating element, which can result in uneven drying or some portions overheating.

The best way to dry filament is by using a dedicated filament dryer. These dryers typically have a spooling cylinder recessed within an enclosed chamber. Temperature-controlled hot air is pumped into the chamber to remove moisture, which passes through a release vent. The spool can rotate for even heating to prevent filament warping.

It can be difficult to tell if your filament is wet simply by looking at it. However, you will be able to tell once you start printing with it. A wet filament will produce a popping/cracking sound when extruding, almost like the sound of making popcorn. Oozing can also be observed if the extruder motor has stopped but the material is still coming from the hot end.