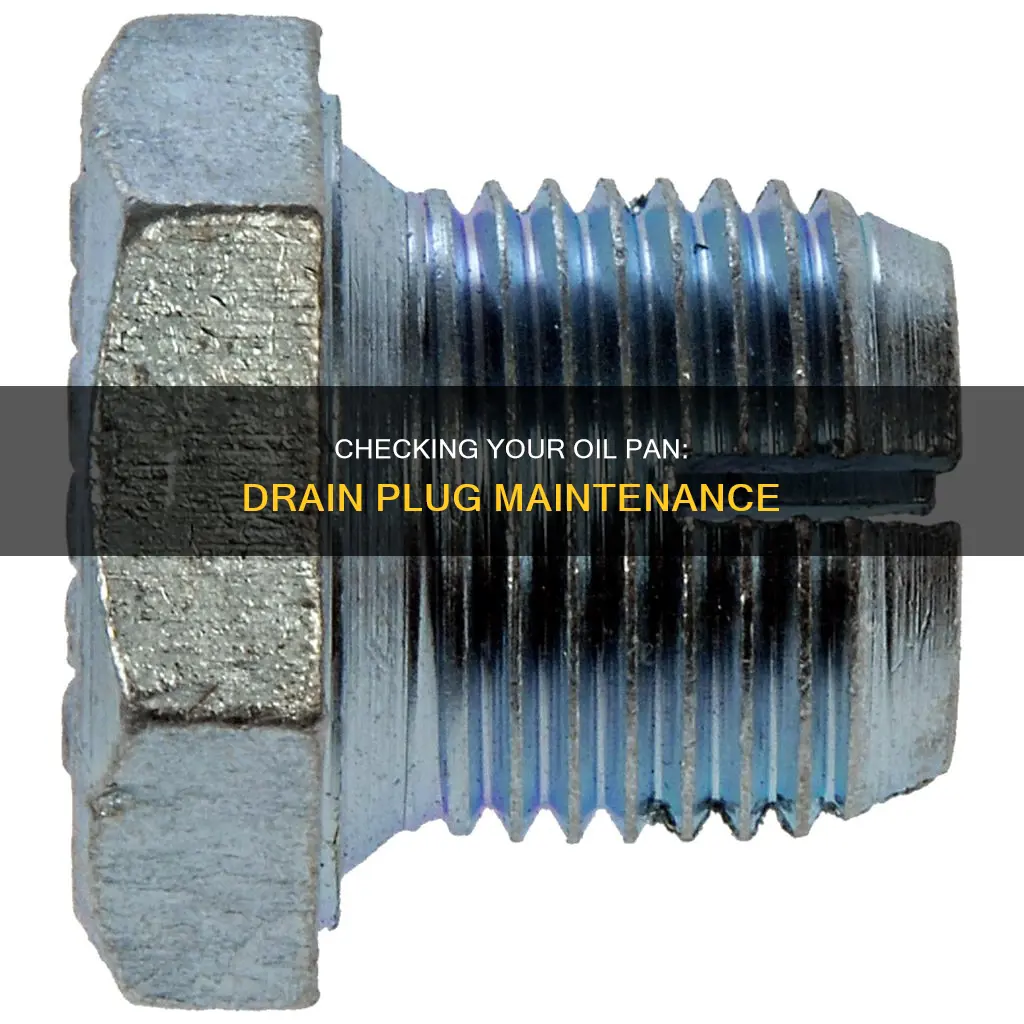

The oil pan drain plug is a crucial component in your vehicle's engine, and it's important to check it regularly to prevent leaks and other issues. Over time, the drain plug can become worn or damaged, leading to potential oil leaks. Checking the drain plug involves inspecting the threads for any signs of stripping or damage and ensuring that it is tightened securely but not overtightened. It is also important to replace the gasket, a copper washer, at every oil change as overtightening can lead to a rounded or stuck bolt. In some cases, you may need to replace the oil pan and drain plug if they are damaged beyond repair. To avoid further complications, it is recommended to use the right tools and techniques when checking and tightening the oil pan drain plug.

| Characteristics | Values |

|---|---|

| How to check if the oil pan drain plug is bad | Check if there is an oil leak. |

| How to prevent oil pan drain plug from wearing out | Change the plug washer often. |

| How to check if the oil pan drain plug is tightened properly | It should be tightened finger-tight where the gasket touches the drain pan surface, then roughly a quarter turn on the drain plug. |

| How to remove a stripped oil pan drain plug | Use a wrench, a socket and ratchet, or vice grips. |

| How to remove a rounded oil pan bolt | Use a bolt extractor socket. |

What You'll Learn

Warm your engine for 5-10 minutes before checking the oil drain plug

Warming up your engine for 5-10 minutes before checking the oil drain plug is a good idea for several reasons. Firstly, it helps to thin out the oil, reducing its viscosity. This means the oil will flow better, allowing more of it to drain out of the engine and into the pan. Warmer oil also picks up more contaminants and holds them in suspension, so you'll remove more unwanted gunk when you drain the oil.

However, you should be cautious when dealing with warm oil, as it can reach very high temperatures and cause burns. It is recommended that you wait at least 15 minutes after running the engine to allow the oil to cool slightly until it's just warm. This will ensure that the oil is still flowing well but is less likely to cause injury.

Additionally, it's important to note that modern cars with electronic oil level controllers require warm oil for a proper measurement. Manufacturers of these vehicles recommend checking the oil when it's warm, as it provides a more accurate result. Therefore, warming up your engine for a few minutes before checking the oil drain plug can be beneficial for both the effectiveness of the oil change and your safety.

Loaf Pan: Bread Baking Essential?

You may want to see also

Use the right tools to remove the drain plug

Using the right tools to remove the drain plug is crucial to avoid causing further damage. The correct tools will depend on the specific situation and the condition of the drain plug. Here are some common tools and techniques that can be used:

- Socket Wrench: Socket wrenches are commonly used to loosen and tighten drain plugs. It is important to use the proper socket size that matches the oil drain plug. Using a socket wrench with a longer handle can provide extra torque, making the task easier.

- Hammer: If the drain plug is stuck, lightly tapping it with a hammer in the right direction can help loosen it. Be careful not to damage the drain plug or its teeth.

- Rust Remover and Lubricants: Spraying a rust remover or lubricant on the drain plug can help dissolve sludge and rust, making it easier to remove.

- Gator Grip: A Gator Grip is a universal wrench socket that can be used with various plugs, sockets, and bolts. Its adjustable teeth allow it to grip different shapes securely.

- Vice Grips: If the drain plug is stripped, using a pair of round-jaw vice grip pliers can help to remove it. Place the pliers around the stripped drain plug and turn counterclockwise to loosen it. If it doesn't move, gently tap the vice grips with a hammer.

- Bolt Extractor Socket: If the bolt is rounded, a bolt extractor socket can be used. This tool is designed to grip and release rounded bolts. You may need to gently hammer it onto the bolt before turning it with a ratchet.

- Drill: As a last resort, if the bolt is still stuck, you can drill a hole into the center of the drain plug. Drilling in reverse may help to pull out the bolt. However, this method should be approached with caution, as it can potentially damage the oil pan.

It is important to assess the condition of the drain plug and choose the appropriate tools to avoid causing further damage. If you are unsure or uncomfortable with performing this task, it is always best to seek the help of a professional mechanic.

Kitchenware Conundrum: Pots and Pans, Dishes?

You may want to see also

Check the threads on the drain plug for damage

Checking the threads on your oil pan drain plug for damage is an important step in regular car maintenance. Over-tightening or cross-threading the oil drain bolt can damage the threads in the pan, causing oil to leak out around the bolt. This can be costly to repair, so it is important to regularly check the threads on your oil pan drain plug for any damage.

To check the threads on your oil pan drain plug for damage, you will first need to locate the drain plug and remove it using the correct size socket. Once the drain plug has been removed, you can inspect the threads for any signs of damage. Look for any stripping or cross-threading on the threads, as this can indicate that the bolt has been over-tightened. If the threads appear to be damaged, you may need to repair or replace the drain plug.

There are several options for repairing a damaged oil pan drain plug. One temporary solution is to use a rubber drain plug, which can be installed as a short-term fix until you are able to make a more permanent repair. Another option is to use a helicoil, which is a hardened steel thread insert that comes in various sizes and thread pitches. A third option is to use a TIME-SERT repair kit, which includes new oil drain bolts and sealing washers, and is designed specifically for repairing damaged oil pans.

To prevent damage to the threads on your oil pan drain plug, it is important to be careful when tightening the bolt. Avoid using an impact gun, as this can over-tighten the bolt and damage the threads. Instead, tighten the bolt by hand or with a socket wrench, being careful not to apply too much force. By regularly checking the threads on your oil pan drain plug for damage and taking care when tightening the bolt, you can help to avoid costly repairs and keep your car running smoothly.

Detroit-Style Pizza Pan: Seasoning Secrets

You may want to see also

Check the gasket for wear and replace if necessary

When checking your oil pan drain plug, it is important to inspect the gasket for any signs of wear and replace it if necessary. A gasket is a mechanical seal that fills the space between two mating surfaces to prevent leakage. It is typically made of rubber, metal, or rope and can be found in various parts of a vehicle, including the oil pan.

Over time, the gasket on your oil pan drain plug may wear out and need to be replaced. Here are some detailed steps to help you check the gasket and replace it if necessary:

- Locate the oil pan drain plug: The oil pan is usually located at the bottom of the engine, and the drain plug is a small bolt or screw that can be removed to drain the oil.

- Remove the drain plug: Place a container under the drain plug to catch any oil drips. Use the appropriate tool to unscrew the drain plug carefully.

- Inspect the gasket: Once the drain plug is removed, you will see the gasket, which is a thin, flexible ring that creates a seal between the drain plug and the oil pan. Look for any signs of wear, tear, cracks, or damage on the gasket.

- Replace the gasket if necessary: If the gasket shows any signs of wear or damage, it is important to replace it. You can find replacement gaskets at most auto parts stores. Simply remove the old gasket carefully and install the new one, ensuring it is securely in place.

- Reinstall the drain plug: After inspecting or replacing the gasket, screw the drain plug back into place tightly, but be careful not to over-tighten it, as this can cause damage.

By following these steps, you can ensure that your oil pan drain plug has a functional gasket, preventing oil leaks. Remember to wear appropriate safety gear, such as gloves and eye protection, when performing these tasks. If you are unsure about any part of the process, it is best to consult a qualified mechanic.

Hearty Servings from an 8x8 Pan

You may want to see also

Tighten the oil pan plug without overtightening

To tighten the oil pan plug without overtightening, follow these steps:

Firstly, it is important to understand the consequences of over-tightening the oil drain plug. Excessive force during installation can damage the oil pan's threads, leading to costly repairs. It can also cause leaks by deforming the gasket or washer, creating an imperfect seal. Therefore, it is crucial to exercise caution when tightening the plug.

Now, let's get into the step-by-step guide:

- Hand-Tighten the Plug: After draining the old oil, insert the oil drain plug into the drain hole by hand. Ensure that it is gently threaded into place and not cross-threaded. Use a firm grip to turn the plug clockwise until it sits flush with the oil pan.

- Use a Wrench to Snug It Up: Once the plug is hand-tightened, use an appropriate wrench or socket size to snugly turn the plug until it stops. You will need to turn the wrench an additional quarter turn to ensure the plug is secure and to prevent it from loosening during operation.

- Adhere to Torque Specifications: The recommended torque specification for the oil drain plug is between 20-30 foot-pounds of torque. This can be described as "hand-tight, plus a little more." Using a torque wrench can help you achieve this specification.

By following these steps, you can effectively tighten the oil pan plug without overtightening it, ensuring a secure fit and avoiding potential damage to your vehicle's engine.

Washer Drain Pan: Second Floor Necessity?

You may want to see also

Frequently asked questions

If you notice an oil leak from your car, this could be a sign of a bad oil drain plug.

If your oil drain plug is worn, this could lead to an oil leak.

If you overtighten the oil pan drain plug, it can strip the bolt and make it difficult to remove.

Over-tightening the oil drain plug can strip the threads. This can happen if you tighten the bolt by turning it clockwise when you intend to loosen it.

You can try to remove the stripped bolt with a wrench, a socket and ratchet, or vice grips. Apply upward force and wedge the bolt out with a screwdriver.