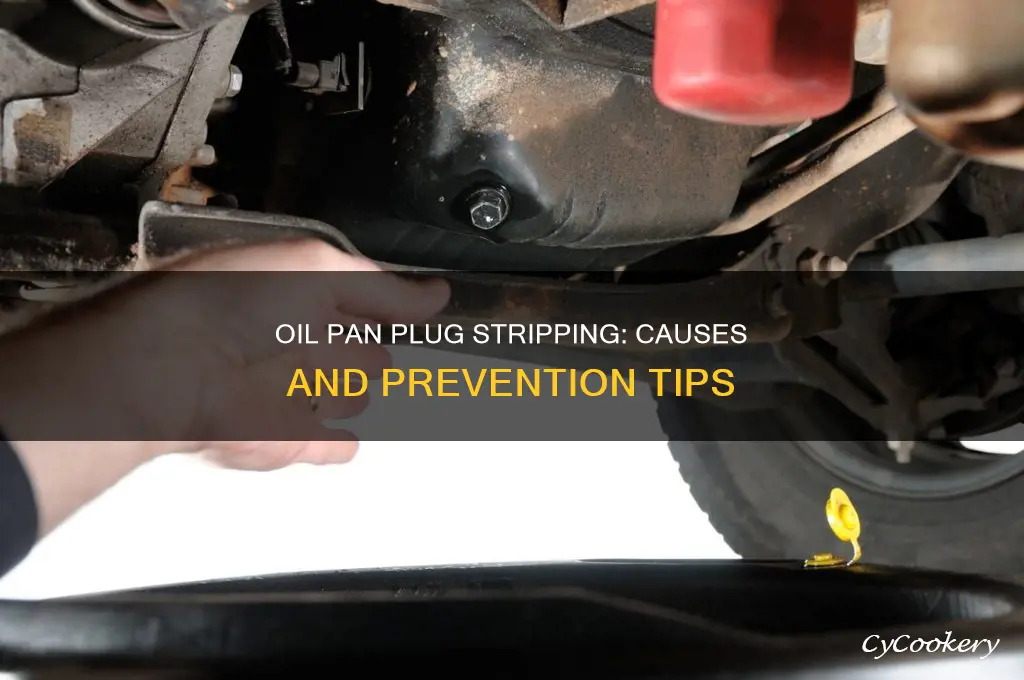

An oil pan plug can get stripped due to several reasons. One of the most common causes is over-tightening, which can damage the threads of the drain plug or oil pan. This often occurs when a power tool is used and too much force is applied when screwing the plug into place. Using the wrong tools, such as an under-sized socket or not using a torque wrench, can also lead to a stripped oil pan plug. Additionally, cross-threading, which happens when the plug is not installed straight and is forced into place, can also result in a stripped plug.

| Characteristics | Values |

|---|---|

| Cause of stripping | Over-tightening |

| Cause of stripping | Use of power tools |

| Cause of stripping | Use of wrong-sized tools |

| Cause of stripping | Cross-threading |

| Solution | Use a wrench or socket to remove the drain plug |

| Solution | Turn the bolt counter-clockwise |

| Solution | Use a flathead screwdriver |

| Solution | Use channel-lock pliers |

| Solution | Use a bolt extractor socket |

| Solution | Drill the bolt out |

| Solution | Replace the oil pan |

What You'll Learn

Cross-threading

Angular cross-threading happens when the bolt enters the threaded part misaligned angularly, causing the threads to engage incorrectly. As the bolt is tightened, the threads of the bolt and/or nut fail by shearing. This occurs when the threads of the two components try to engage with at least half a pitch or revolution out of alignment. If tightening continues, the threads become angularly misaligned and structurally damaged.

Parallel cross-threading is more subtle and can occur even without angular misalignment. It usually occurs due to excessive screw rotation speed during insertion. This happens when the tread patterns don't match up perfectly, which is common when using power tools as the threads get "over-torqued".

Viking Cookware: Worth the Hype?

You may want to see also

Overtightening

In some cases, overtightening the oil pan drain plug can make the bolt a little looser than when it was initially installed. The bolt can become stripped and difficult to remove, and it may not come out of the oil pan. This can be a frustrating problem, as it can bring your routine oil change to a halt.

To avoid overtightening the oil pan drain plug, it is crucial to use the right tools and follow the correct procedure. Use a socket or wrench to remove the drain plug, and always turn the bolt counterclockwise to loosen it. Be careful to turn the wrench clockwise to avoid accidentally overtightening and stripping the drain plug.

Additionally, it is important to check the threads on the drain plug regularly. If the threads are stripped, the drain plug will need to be replaced. By following these simple precautions, you can help prevent the oil pan drain plug from becoming stripped due to overtightening.

Goummia's Air Fryer Pan: Non-Stick and BPA-Free?

You may want to see also

Using the wrong tools

To avoid this, it is important to use the right tools, such as a socket or wrench, to remove the drain plug. A torque wrench can also be used to prevent over-tightening and ensure that the drain plug is tightened properly. By following the correct procedures and using the appropriate tools, you can significantly reduce the chances of stripping the oil pan plug.

In addition to using the correct tools, it is crucial to have the right-sized tools. Information about the appropriate drain plug size for a specific vehicle can often be found online or by referring to a manufacturer-specific service manual. By using the correct size, you can reduce the likelihood of rounding off the drain plug's hexagonal head.

Furthermore, it is important to note that overtightening the oil pan drain plug can also lead to stripping. This can occur when you accidentally tighten the bolt by turning it clockwise when intending to loosen it. Therefore, it is crucial to be cautious and ensure that you are tightening and loosening the oil pan bolt correctly to prevent stripping.

Conditioning Stainless Steel: Secrets Revealed

You may want to see also

Using a power tool

Using power tools to fix a stripped oil pan plug can be done in several ways. Here is a step-by-step guide on how to do it:

Using Vice Grip Pliers

To remove a stripped oil drain plug, use a pair of vice grip pliers to grip the oil drain plug tightly. Turn the pliers counterclockwise, and use a hammer if more force is needed. Once the plug is loose enough, you should be able to unscrew it.

It is recommended to use the round-jaw variety of vice grip pliers. The flat-jaw type may have trouble locking around the bolt, and without a tight grip, the plug won't be removable.

Using a Flathead Screwdriver

If you need to apply outward force on the plug, a flathead screwdriver can be used. Wedge the screwdriver between the external surface of the oil pan and the underside of the drain plug's head. This can help engage any remaining threads, making it easier to turn the plug counterclockwise and remove it.

Using a Wrench or Socket Wrench

A wrench or socket wrench can be used to turn the stripped drain plug counterclockwise and loosen it. If the head of the drain plug is flush against the body of the oil pan, channel-lock pliers can be used to rotate the plug while pulling outward.

Using a Bolt Extractor Socket

If the drain plug has a rounded-off head, a specialty socket called a bolt extractor can be used. This type of socket has spiralled internal grooves that bite into the head of the bolt, simplifying its extraction.

Lightly tap the socket onto the head of the drain plug with a dead blow hammer, then turn it with a ratchet to release the stuck bolt.

Using a Drill

If the bolt is still stuck, you can try drilling it out with a small drill bit. Drilling in reverse may help pull the bolt out. Alternatively, drill a slightly larger hole and use a bolt extractor to remove the bolt.

Power Tool Precautions

When using power tools to fix a stripped oil pan plug, it is important to exercise caution to avoid further damage to the plug or the oil pan. Always use the correct size and type of tool for the job, and avoid using excessive force, as this can strip the head further or damage the oil pan.

Additionally, always wear appropriate safety gear, such as eye protection and gloves, when operating power tools.

The Art of Pan-Searing Scallops: A Cast Iron Guide

You may want to see also

Using an under-sized socket

Using an undersized socket to remove an oil pan plug can lead to stripping. This is because the socket can round off the head of the drain plug, preventing a wrench or socket from being properly applied during removal. This is one of the most common causes of a rounded-off drain plug.

To avoid this, it is important to use a properly sized wrench or socket when removing the oil pan plug. Information on the correct drain plug size for a particular vehicle can be found online or in a manufacturer-specific service manual.

If the head of the drain plug has been rounded off, a different strategy is needed to remove it. One method is to use a specialty socket called a bolt extractor, which has spiralled internal grooves. This can be gently hammered onto the head of the drain plug, causing the internal grooves to bite into the head, making it easier to extract.

Once the stripped drain plug has been removed, it is important to check the threads on the drain plug and the oil pan's drain hole. If the threads are stripped, the drain plug or oil pan may need to be replaced.

To prevent stripping in the future, it is important to use the correct tools and follow the manufacturer's specifications for tightening the drain plug. A torque wrench can help ensure that the drain plug is tightened to the correct torque value without being over-tightened.

Keep Carbon Steel Pan Seasoned, Here's How

You may want to see also

Frequently asked questions

Your vehicle’s oil drain plug is located on either the bottom or side of its oil pan. It keeps the motor’s lubricant from pouring out because of the constant effects of pressure created inside of the vehicle’s crankcase and gravity itself.

An oil pan plug can get stripped by either cross-threading or overtightening. Cross-threading happens if/when the plug isn’t installed straight and ultimately gets forced the rest of the way. Overtightening occurs when there’s a power tool used, and it exerts too much force to screw the plug into place.

To prevent an oil pan plug from getting stripped, use a properly sized wrench or socket during every oil change and adhere to the appropriate torque specifications when tightening the plug.

If your oil pan plug is stripped, you may notice that it is difficult to remove. You may also see that oil is leaking from the plug, which can ultimately lead to major engine failure.

If your oil pan plug is stripped, you can attempt to remove it yourself using a wrench, socket and ratchet, or vice grips. If you are unable to remove the stripped plug, you may need to replace the oil pan and drain plug.