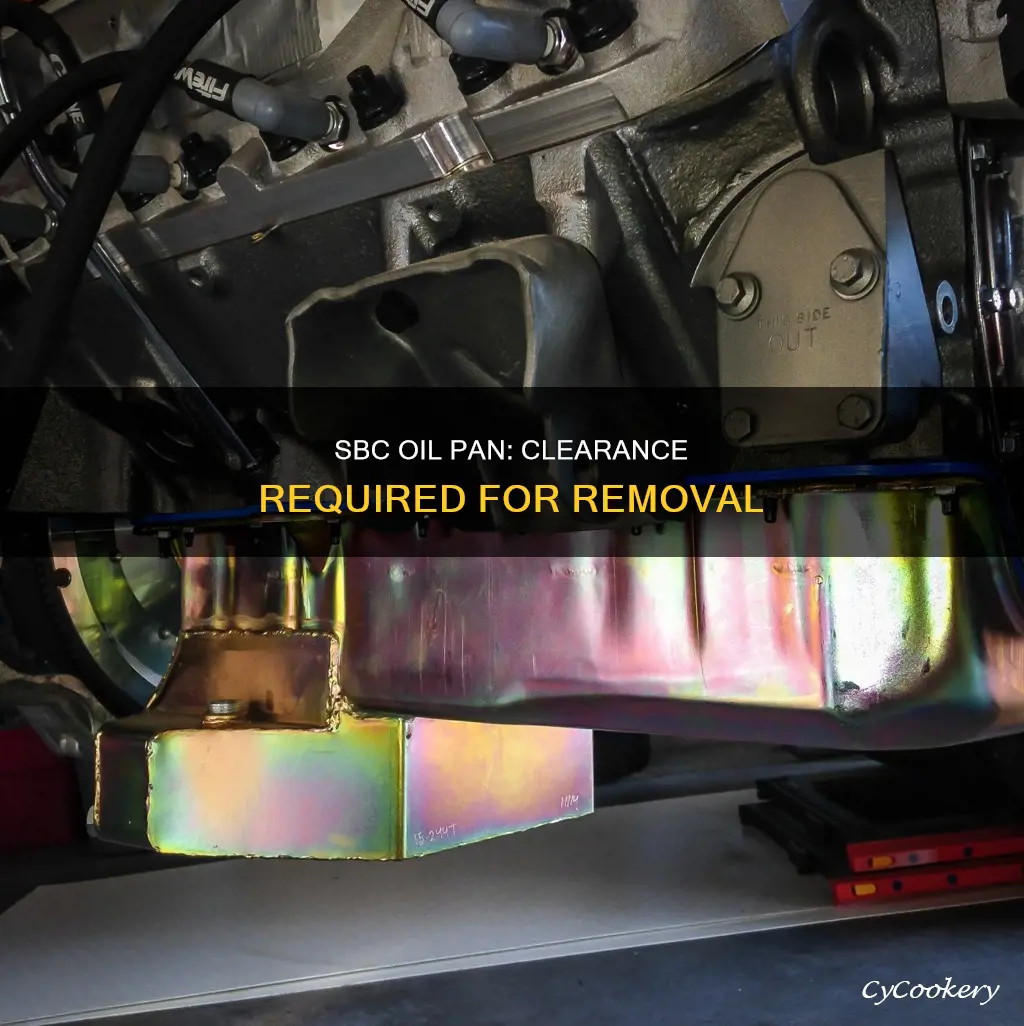

Removing the oil pan from an SBC engine can be a challenging task, and the amount of clearance needed depends on the specific vehicle and oil pan design. In some cases, it may be necessary to raise or remove the engine to gain sufficient clearance.

For example, in a Chevy Chevelle with a small block engine, it is generally recommended to pull the engine out for easier access and to avoid potential damage to the new seal. However, it is technically possible to remove the oil pan without removing the engine by raising the engine, placing blocks of wood between the motor mounts and frame mounts, and then sliding the pan out. This method requires careful positioning of the engine and can be more challenging and time-consuming.

In other cases, such as with an old Mercedes sedan with an SBC 350 engine, the issue may be a lack of clearance due to the tall height of the oil pan. This can prevent the addition of an air filter on top of the carburetor. To address this, modifications can be made to the cross member or steering linkage, or a dry sump kit can be installed, although this may be an expensive option.

Therefore, the amount of clearance needed to remove the oil pan from an SBC engine can vary depending on the specific vehicle and engine configuration, and there are various methods and workarounds that can be considered to gain the necessary access.

What You'll Learn

SBC oil pan removal without removing the engine

Removing the oil pan from an SBC engine can be a challenging task, and it is often recommended to remove the engine entirely to access the oil pan and replace the gasket. However, it is possible to remove the oil pan without taking out the engine, and here is a step-by-step guide on how to do it:

Step 1: Prepare the Vehicle

Before starting, ensure you have a clear and safe workspace. Park the vehicle on a level surface, engage the parking brake, and block the rear wheels for added safety. Place a drain pan or container underneath the oil pan to catch any dripping oil.

Step 2: Raise the Vehicle and Drain Oil

Using a jack, safely raise the vehicle and secure it on jack stands. Locate the oil drain plug and place a suitable container underneath. Remove the drain plug using the appropriate tool, allowing the oil to drain completely. Replace the drain plug securely when finished.

Step 3: Access the Oil Pan

To access the oil pan, several components may need to be removed or loosened, depending on your vehicle's configuration. These may include the air cleaner, distributor cap, fan shroud, upper radiator panel, fuel pump, transmission converter dust shield, exhaust manifolds or headers, motor mount bolts, and the starter. Loosen or remove these components as necessary to create sufficient workspace and access the oil pan.

Step 4: Rotate the Crankshaft and Lift the Engine

Rotate the crankshaft so that the timing mark on the balancer is at the 6 o'clock position, ensuring that all journals are facing upwards. This will provide the necessary clearance to remove the oil pan. Use a floor jack to carefully lift the engine a few inches. It is recommended to use a block of wood or a suitable jack pad between the jack and the oil pan to distribute the load evenly.

Step 5: Support the Engine and Remove the Oil Pan

Once the engine is lifted, place wooden blocks or appropriate supports between the motor mounts and the frame to securely hold the engine in the raised position. Double-check that the engine is stable and securely supported before proceeding. With the engine supported, remove the oil pan bolts and carefully slide out the oil pan. You may need to turn the crankshaft slightly to clear the oil pan completely.

Step 6: Clean and Inspect the Gasket Surface

With the oil pan removed, take the opportunity to clean the gasket surface and inspect for any debris or damage. Ensure that the surface is clean and free of old gasket material before installing the new gasket.

Step 7: Install the New Gasket and Reassemble

Apply a suitable gasket sealant or RTV to the gasket surfaces as recommended by the manufacturer. Carefully position the new gasket, ensuring it is correctly aligned. Reinstall the oil pan, tightening the bolts securely but being careful not to over-tighten.

Step 8: Lower the Engine and Reassemble Components

Once the new gasket and oil pan are installed, you can lower the engine back into its original position. Remove the wooden blocks or supports and carefully lower the engine using the floor jack. Reinstall any components that were previously removed, such as the motor mounts, starter, exhaust manifolds, and distributor cap.

Step 9: Refill Oil and Check for Leaks

With the engine reassembled, refill the engine with the appropriate amount and type of oil. Check for any leaks around the oil pan gasket and tighten the bolts if necessary. Start the engine and check for any signs of leakage. Ensure that the oil pressure is stable and within the normal range.

By following these steps, you can successfully remove and replace the oil pan gasket on an SBC engine without completely removing the engine. However, it is important to work carefully and ensure that the engine is securely supported at all times to avoid any potential damage or injury.

Pork Brisket Pan-Seared to Perfection

You may want to see also

Oil pan to crossmember clearance

When it comes to oil pan to crossmember clearance, the general consensus is that having at least a 1/4" static clearance is ideal. This takes into account potential engine movement and deflection during acceleration, as well as wear on the mounts over time.

In some cases, individuals have reported having as little as an 1/8" clearance or even just enough room to slide two sheets of heavy paper between the pan and crossmember. However, it is generally recommended to aim for a slightly larger gap to avoid potential issues.

If you find that your oil pan is too close to the crossmember, there are a few options to consider. One solution is to modify the existing crossmember by cutting and reshaping it to provide more clearance. Another option is to explore alternative oil pans, such as front sump or rear sump pans, which may have a lower profile and offer more clearance. Additionally, engine mounts can be adjusted or spacers can be used to raise the engine and create more space between the oil pan and crossmember.

It is important to note that attempting to remove the oil pan without sufficient clearance can be challenging and may require raising or removing the engine. This process can be complex and time-consuming, so it is generally recommended to ensure adequate clearance before attempting any maintenance or modifications.

The Ultimate Guide to Acquiring a Flame Pan

You may want to see also

Oil pickup/bottom of pan clearance

The distance between the oil pickup and the bottom of the pan is crucial for optimal engine performance. While the exact clearance can vary depending on the specific engine and application, ensuring sufficient clearance is essential to prevent issues such as oil starvation and engine damage.

A general rule of thumb for oil pickup to pan clearance is to maintain a distance of between 3/8" and 1/2". This range has proven effective in various applications and is often recommended by engine builders and racers. However, it's important to note that different engines and usage scenarios may require slightly different clearances.

For example, Ford Racing suggests a minimum clearance of 0.25" and a preferred range of 0.25" to 0.375" for their engines. This clearance helps prevent the oil pan from blocking the pickup, which can lead to catastrophic engine failure. Additionally, it's recommended to install a small stop or bump at half the clearance height to prevent the pan or pickup tube from flexing and causing issues.

The oil pickup's position relative to the pan is also critical. On stock vehicles, the pickup is angled relative to the pan rail, with the screened intake positioned forward in the pan well. This design considers that these vehicles typically brake harder than they accelerate. In contrast, drag racing pans have the pickup positioned all the way rearward to account for the intense G-forces experienced during launches and wheelies.

When installing an oil pickup, it's crucial to use the correct tools and techniques. Some stock pickups require pressing into place, and improper installation can result in insufficient clearance. This can lead to oil slosh during hard acceleration, uncovering the pickup and potentially causing oil pressure issues. Therefore, it's essential to follow the manufacturer's recommendations and guidelines for the specific engine and application.

Galvanized Metal Pans: Safe for Meat?

You may want to see also

SBC oil pan alternatives

When it comes to SBC oil pan alternatives, there are a few options to consider. One suggestion is to modify the cross member by cutting out the centre and welding it closed in a new shape, as well as adjusting the steering linkage. This can help address clearance issues without the need for a new oil pan.

Another alternative is to explore different types of oil pans, such as front sump pans or rear sump pans, which may provide the necessary clearance. In some cases, slight modifications to the pan may be needed. For instance, an early Nova oil pan or a custom-made pan with a shortened sump and widened shape could be potential options.

If you're open to a more significant change, a dry sump kit can effectively reduce the height of the oil pan. However, this option tends to be quite expensive, with kits ranging from $1200 to $4000.

It's worth noting that the specific alternatives may depend on the vehicle's make and model, as well as the configuration of the engine and oil pan. It's always recommended to consult with a professional or a mechanic before making any modifications or choosing alternative solutions.

Cast Iron Cooking: Preventing Gold Sticking

You may want to see also

SBC oil pan removal tips

Removing the oil pan from an SBC engine can be a challenging task, but with the right tools, preparation, and techniques, it can be accomplished successfully. Here are some detailed instructions and tips to guide you through the process:

Step 1: Prepare the Vehicle

Before beginning the oil pan removal process, it is important to ensure that you have a clear and safe work area. Park the vehicle on a level surface, engage the parking brake, and place wheel chocks around the tires to prevent accidental movement. Gather all the necessary tools and materials, including a jack, jack stands, wrenches, and a new oil pan gasket. Place a drain pan or container under the oil pan drain plug to catch any remaining oil.

Step 2: Drain the Oil

Position the drain pan or container under the oil pan drain plug. Remove the drain plug using a wrench, allowing the oil to drain completely. Once the oil has drained, replace the drain plug securely to prevent leakage during the removal process.

Step 3: Remove Accessory Components

To access the oil pan, several components may need to be removed or loosened, depending on your specific vehicle. These may include the air cleaner, distributor cap, fan shroud, upper radiator panel, starter, exhaust pipes, motor mount bolts, transmission, driveshaft, and clutch components. It is important to refer to a repair manual specific to your vehicle for detailed instructions on which components need to be removed.

Step 4: Raise the Engine

Place a jack under the engine and raise it slightly to take the load off the motor mounts. Support the engine securely with jack stands. If necessary, remove the motor mount bolts to allow for greater engine movement. Be cautious when raising the engine, as raising it too high may cause damage to the transmission or other components.

Step 5: Remove the Oil Pan Bolts

Locate and remove all the bolts securing the oil pan to the engine block. Depending on your engine configuration, you may need to rotate the crankshaft to access all the bolts. Be careful not to strip the threads or damage the bolt heads during removal.

Step 6: Lower the Oil Pan

With all the bolts removed, gently lower the oil pan. You may need to use a pry bar or screwdriver to carefully pry it away from the engine block, being cautious not to damage the mating surfaces. Once the oil pan is lowered, clean the gasket surfaces on the engine block and oil pan to prepare for the installation of the new gasket.

Tips for Success:

- Before beginning the removal process, familiarize yourself with the engine and its components by consulting a repair manual or online resources specific to your vehicle.

- Take your time and work carefully to avoid damaging engine components or stripping bolt threads.

- Have a helper assist you during the process, especially when raising and supporting the engine.

- When removing the oil pan bolts, apply penetrating oil and allow it to soak for a few minutes to help loosen any rusted or seized bolts.

- If the oil pan is difficult to remove, use a rubber mallet to gently tap the bottom edge of the pan while prying to loosen it.

- When installing the new oil pan gasket, ensure that the gasket is properly aligned and seated before tightening the bolts.

- Always refer to the torque specifications provided by the manufacturer when tightening the oil pan bolts to prevent leakage and ensure even clamping pressure.

Removing a BMW PAN: A Step-by-Step Guide

You may want to see also

Frequently asked questions

It is possible to remove the oil pan without removing the engine, but it is not recommended. Removing the engine makes the job easier and less frustrating.

First, drain the oil. Then, remove the exhaust y-pipe, starter, distributor cap, torque converter dust shield, and two motor mount bolts. Next, lift the front of the engine until the pan comes out the back of the motor. Finally, slide the oil pan out.

It is not recommended to remove the oil pan with the engine still in the car. However, if you must, you will need to raise the engine and place blocks of wood between the motor mounts and the frame mounts. You will also need to disconnect and remove several parts, including the exhaust, starter, distributor cap, torque converter dust shield, and motor mount bolts.

Try using a rubber mallet to hit the bottom edge of the oil pan while prying it off. Be careful not to disfigure it with your pry bar, as this can cause future leaks.