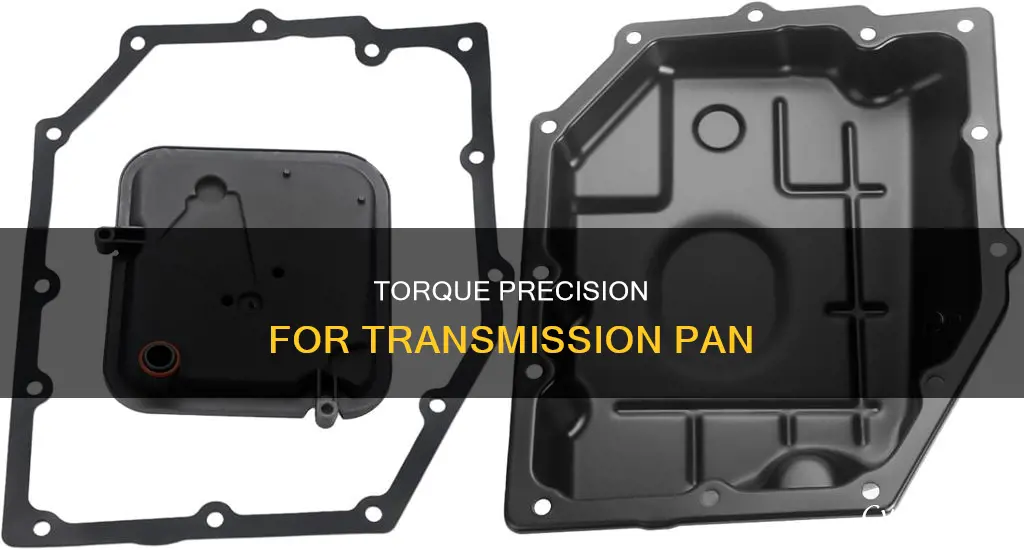

There is no one-size-fits-all answer to the question of how much torque to apply to a transmission pan. The torque required varies depending on the vehicle's specific transmission pan bolts and gasket type. Over-tightening is a common issue, which can lead to leaks and other problems. It is crucial to refer to the manufacturer's instructions or a trusted mechanic to ensure the correct torque is applied, as it typically falls between 7 and 15 ft-lbs.

What You'll Learn

Torque specs for transmission pan bolts

Torque specifications for transmission pan bolts are crucial to ensuring a proper seal and preventing leaks. The correct torque value depends on the vehicle's specific make and model, with different torque specs for Nissan, Ford, Chevy, and Toyota vehicles.

For instance, the torque spec for the Chevy Silverado's 6L80 trans pan bolts is 80 inch-pounds, while for the Ford F-100's C6 automatic transmission, the torque spec for the transmission pan bolts is 13 foot-pounds. On the other hand, the Toyota 4Runner's transmission pan bolts have a torque spec of 65 inch-pounds.

It is important to note that over-tightening transmission pan bolts can lead to stripped threads, warped flanges, and oil leaks. Therefore, it is always recommended to follow the manufacturer's torque specifications and use a torque wrench to achieve the desired level of tightness.

When it comes to tightening transmission pan bolts without a torque wrench, some mechanics suggest tightening the bolts gently and checking for leaks, then tightening them further if necessary. Others recommend using a 3/8 ratchet and turning it by holding the head only, which provides a better feel for the torque.

Resurfacing Steel Pans: DIY Guide

You may want to see also

Using a torque wrench

Adjusting the Wrench:

Before using your torque wrench, you need to adjust it to the desired torque setting. Here's how to do it:

- Loosen the locking knob at the end of the wrench's handle by twisting it counterclockwise. This will allow you to change the settings.

- Locate the torque measurements on the wrench. These are usually in foot-pounds (lb·ft) or meter kilograms (kg·m). The horizontal hash marks represent increments of 10 or 20 lb·ft, while the vertical marks on the dial indicate 1 lb·ft increments.

- Adjust the handle's position to the desired torque value. Hold the body of the wrench with your non-dominant hand and turn the handle with your dominant hand. Turn it clockwise to increase the torque and counterclockwise to decrease it. Stop turning when the top edge of the handle lines up with the closest horizontal hash mark.

- Fine-tune the torque setting by twisting the top dial. This allows you to make precise adjustments. Turn the dial clockwise to increase the torque and counterclockwise to decrease it. The final torque value is the sum of the handle's position and the dial's setting.

- Lock in the setting by tightening the locking knob at the end of the handle. Turn it clockwise until it's secure.

Tightening Nuts and Bolts:

Once your torque wrench is adjusted to the correct setting, you can proceed to tighten the nuts and bolts on your transmission pan:

- Attach a socket to the head of the wrench that matches the size of the nut or bolt. Slide it into the head of the wrench until it clicks into place. You may need a socket extender for hard-to-reach areas.

- Screw the nut or bolt on by hand until it's tight. This ensures that it's properly aligned before using the torque wrench.

- Fit the wrench's socket over the nut or bolt. Ensure that it fits tightly and doesn't feel loose.

- Turn the wrench's handle clockwise to tighten the nut or bolt. Continue turning until you hear a click or feel resistance. This indicates that you've reached the desired torque setting.

- Stop turning the wrench once it clicks or resists further turning. Forcing it further can damage the nut, bolt, or the wrench itself.

Maintenance and Additional Tips:

To ensure the accuracy and longevity of your torque wrench, proper maintenance is essential:

- Always dial the wrench back to zero before putting it away. Leaving it at a torque setting can affect its calibration over time.

- Clean dirty or rusty nuts and bolts before tightening them. Use a towel, rag, or wire brush to remove rust and grime. You can also use a degreaser like WD-40.

- Have your wrench calibrated regularly. It's recommended to calibrate your torque wrench at least once a year or after 5,000 clicks.

- Be careful not to drop your wrench, as it can affect its calibration. Always carry it with both hands when moving around.

- Torque wrenches are for tightening only. Use a different tool, such as a socket wrench, for loosening nuts and bolts.

Spraying Pizza Pans: To Spray or Not to Spray?

You may want to see also

Gaskets and sealing

When it comes to the torque specs for transmission pan bolts, it is important to be aware of the potential for over-tightening, which can cause damage to the pan gasket. The torque required varies depending on the type of gasket used, with a range of 7-12 ft-lbs being commonly recommended. It is also advised to take your time and work with care, as the process requires dexterity to hold the pan, keep the gasket in place, and tighten multiple bolts simultaneously.

For fibre ATP gaskets, the manufacturer's instructions typically recommend a torque of 10-12 lbs if no specific value is provided. However, it is worth noting that some service manuals suggest a higher torque of 97 lb, which may be intended for OEM-style gaskets made of metal or other reusable materials. It is crucial to check the units used (inch-pounds or foot-pounds) to ensure accurate torque application.

In terms of gaskets and sealing, it is generally recommended to use rubber or composite gaskets without any additional sealer. Adding sealant can create more work during future maintenance and is often unnecessary. Gaskets made of rubber or composite materials typically provide an effective seal without the need for additional substances. However, in certain cases, such as when the mating surfaces are damaged or gouged, the use of a sealant may be considered.

When installing a rubber gasket, it is recommended to do so without any sealer or RTV (room temperature vulcanizing) silicone. Rubber gaskets are designed to seal effectively on their own, unless the mating surfaces are significantly damaged. In such cases, the use of a sealant may be warranted.

For transmission pans that originally used sealant instead of a gasket, it is advisable to switch to a gasket during the first fluid change. This simplifies future maintenance and reduces the effort required to remove the pan. The use of a composite gasket is generally preferred over cork gaskets, as they are less prone to splitting.

In summary, the torque required for transmission pan bolts depends on the type of gasket used, with a range of 7-12 ft-lbs being commonly recommended. It is important to avoid over-tightening, which can damage the gasket. Gaskets made of rubber or composite materials are typically used without additional sealant and provide an effective seal. In certain cases, such as damaged mating surfaces, the use of a sealant may be considered.

Pasta Portioning for a Pan of Ziti

You may want to see also

Over-tightening

One way to avoid over-tightening is to start by hand-tightening all the bolts, then using a torque wrench to finish. Another method is to use a 1/4" drive ratchet and tighten by hand, using your wrist as a torque meter. This method requires experience and a good feel for how much torque is being applied. It is also important to be careful not to cross-thread the bolts, as this can also damage the pan and cause leaks.

If you are using a rubber gasket on the pan, you should tighten until you see a slight deflection of the gasket. This takes practice to get the feel for, but you will see the gasket squish just a little and bulge out instead of being straight. For cork gaskets, it is important not to re-tighten, as this will cause leaks.

To summarise, over-tightening your transmission pan bolts can cause leaks and damage to the pan gasket and should be avoided. Take your time, use the correct tools, and be mindful of the torque you are applying to avoid issues.

Steel Gauge Guide for Floor Pans

You may want to see also

Bolt snapping

When tightening bolts to a torque specification, it is important to be cautious to avoid bolt snapping. Bolt snapping can be caused by several factors, including:

- Physical limitations or substandard fasteners: Ensure that there is adequate clearance and the correct type of fasteners are being used.

- Inadequate lubrication: While some bolts require lubrication, others should be installed dry. Using the wrong type or amount of lubrication can lead to over-tightening and bolt snapping.

- Worn or stripped threads: Cleaning and inspecting the threads for any damage is crucial before attempting to torque the bolt.

- Incorrect torque settings: Using the wrong scale on the torque wrench or applying excessive force can result in bolt snapping.

- Improper tools: Using an incorrect tool or an inadequate setup, such as a long extension, can increase the risk of bolt snapping.

To prevent bolt snapping, it is recommended to use new hardware, ensure clean and undamaged threads, verify the correct torque settings, and choose the appropriate lubricant specified by the OEM. Additionally, using smooth and fast pulls on the torque wrench, rather than going slow, can help prevent bolt snapping in certain situations.

In the context of transmission pan bolts, it is crucial to apply the correct torque to avoid damaging the pan gasket. The recommended torque for transmission pan bolts varies depending on the vehicle and gasket type, typically ranging from 7 to 12 ft-lbs. Over-tightening these bolts can lead to gasket damage and leaks. Therefore, it is essential to follow the manufacturer's specifications and take a cautious approach to avoid bolt snapping and potential damage to the transmission pan assembly.

Pepperoni Personal Pan Pizza Perfection

You may want to see also

Frequently asked questions

The torque spec depends on the type of gasket and vehicle. For a Toyota 4Runner, the torque spec is 65 in-lbs. For a Camaro or Firebird, the torque spec is 10-12 lbs. For a Dodge Challenger, the torque spec is 89 in-lbs. For a 1988 Trans Am GTA, the torque spec is 15 ft-lbs.

The torque spec for a transmission pan with a fiber ATP gasket is 10-12 lbs if not specified by the manufacturer.

It is recommended to tighten the bolts by hand and then torque to 65-75 in-lbs when using a cork gasket. Over-tightening is common and can cause leaks.

The torque spec for a transmission pan with a rubber gasket is 65 in-lbs.

The torque spec for a transmission pan with a Duraprene gasket is 65-75 in-lbs. It is recommended to use no sealer with this type of gasket.