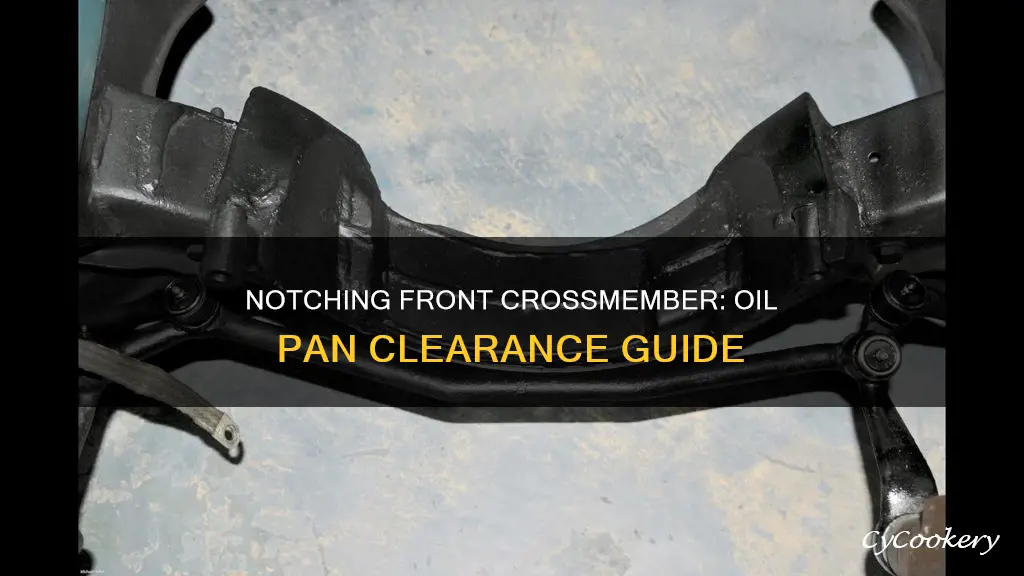

Notching the front crossmember for oil pan clearance is a common issue when swapping engines. The process involves cutting out a section of the crossmember to create clearance for the oil pan. This can be done by cutting out the centre of the crossmember and welding in a tubular bar to connect the two sides, or by using metal plates to box in the cut-out area for reinforcement. Some people also choose to make the new crossmember removable by welding end plates and using bolts to connect it to the original frame. When notching the crossmember, it is important to consider the amount of clearance needed and to brace the frame to prevent twisting. The type of engine mounts used can also affect the amount of clearance, with poly mounts providing more stiffness than rubber mounts.

What You'll Learn

- You may need to notch the crossmember to be able to pull the transmission without lifting the cab

- You can use square tubing instead of regular round tubing

- You can notch the crossmember by cutting out the centre area, plating the sides and welding them in

- You can cut out the top, front and back of the factory crossmember and leave the bottom for support

- You can use a different oil pan that doesn't require notching the crossmember

You may need to notch the crossmember to be able to pull the transmission without lifting the cab

Notching the crossmember is a common modification when performing an engine swap. This process involves cutting away a portion of the crossmember to create clearance for the oil pan. By notching the crossmember, you can avoid the need to lift the cab when pulling the transmission.

When planning to perform a budget engine swap, such as replacing a 4.3 engine with a 5.3 engine, you may encounter clearance issues between the oil pan and the crossmember. This issue can be addressed by notching either the oil pan or the crossmember. Notching the crossmember is often preferred as it is a more cost-effective solution and allows for easier transmission removal in the future.

The notching process typically involves measuring the required clearance and carefully cutting the crossmember to create the necessary space for the oil pan. It is important to ensure that the crossmember remains sturdy and capable of supporting the engine and transmission after the notch has been made. Some reinforcement may be required to maintain the structural integrity of the crossmember.

When deciding on the notch size, it is crucial to consider the type of engine mounts you will be using. Polyurethane engine mounts may require a larger notch compared to the standard rubber mounts. Additionally, the chosen oil pan can also impact the required notch size. Some oil pans, such as the Holley 302-1, are designed to provide more clearance and may not require a notch at all.

It is always recommended to research and plan your engine swap carefully. Taking measurements and considering the specific components you will be using can help ensure a successful swap and avoid the need for multiple attempts at installing the engine. Consulting with experienced individuals or forums related to your specific vehicle and swap can provide valuable insights and guidance.

Little Caesars Pan Pepperoni Pizza Price

You may want to see also

You can use square tubing instead of regular round tubing

When notching a front crossmember for oil pan clearance, you can use square tubing instead of regular round tubing. This option was suggested by a user on the S-10 Forum who planned to use square tubing for their 5.3 engine swap into a Sonoma. They noted that they had access to square tubing and metal plates at work, which would be more cost-effective than purchasing round tubing.

Square tubing can provide sufficient strength and rigidity for this application. However, some considerations should be made regarding tubing thickness and diameter to ensure optimal performance. It is recommended to use tubing with a thickness of at least .120 inches for adequate strength, although thicker tubing may be preferable for more demanding applications.

When designing the crossmember, it is essential to focus on spreading the stresses over a wider area. This can be achieved by tying the tubing into as many legs of the frame as possible. Ideally, you should aim to tie the tubing into the top, bottom, and sides of the frame if possible. This will enhance the structural integrity of the crossmember and improve weight distribution.

Additionally, don't limit yourself to straight tubing designs. You can explore using smaller tubes or incorporating flat plates to connect multiple tubes. By spreading out the load, you can optimize the strength and stability of the crossmember.

In conclusion, square tubing is a viable alternative to round tubing when notching a front crossmember for oil pan clearance. By selecting appropriate tubing thickness and incorporating thoughtful design considerations, you can achieve a sturdy and effective solution.

Get Pan GT Honey: Easy Steps to Follow

You may want to see also

You can notch the crossmember by cutting out the centre area, plating the sides and welding them in

Notching the front crossmember is a common practice when working on car engines, especially when there are oil pan clearance issues. This process involves cutting and removing the centre section of the crossmember, leaving only the sides. Here is a step-by-step guide on how to do it:

Step 1: Prepare the Car

Before you start cutting, make sure your car is securely supported, ideally on jack stands, and the relevant safety precautions are in place.

Step 2: Measure and Mark

Using a tape measure, determine how much space you need to clear the oil pan. Mark the centre area of the crossmember for cutting, ensuring your measurements are accurate and allowing for a bit of wiggle room.

Step 3: Cut Out the Centre

Using an appropriate cutting tool, carefully cut along the marked lines to remove the centre section of the crossmember. Take your time with this step to avoid damaging other parts of the car.

Step 4: Prepare the Plates

Cut two plates from a strong, durable material, such as steel. These plates should be slightly larger than the crossmember's sides, ensuring a snug fit.

Step 5: Weld the Plates

Weld the plates onto the sides of the crossmember, filling the gap created by removing the centre section. Ensure the welds are strong and secure, as this will bear the weight of the engine.

Step 6: Reinforcement

Consider adding additional reinforcement to the modified crossmember, such as square tubing or triangular gussets, to enhance its strength and rigidity.

Step 7: Test Fit

Once the welding is complete and the modified crossmember has cooled, test fit the oil pan to ensure proper clearance. Make any necessary adjustments until the desired clearance is achieved.

Step 8: Final Touches

Paint or coat the modified crossmember and welded areas to prevent corrosion and give it a clean, finished look.

This process of notching the front crossmember by cutting out the centre, plating, and welding is a common solution to oil pan clearance issues, providing the necessary space for engine swaps or modifications while maintaining structural integrity.

Cleaning Cast Iron: Removing Food Without Soap

You may want to see also

You can cut out the top, front and back of the factory crossmember and leave the bottom for support

Notching the front crossmember is a common modification when swapping engines. This process involves cutting away parts of the crossmember to create clearance for the new oil pan. In this case, you can cut out the top, front, and back of the factory crossmember while leaving the bottom intact for support.

Step 1: Prepare the Vehicle

- Park the vehicle on a flat, level surface and engage the parking brake.

- Place jack stands under the vehicle's frame for added stability.

- Raise the front of the vehicle using a jack and support it with jack stands.

- Ensure the vehicle is secure and stable before proceeding.

Step 2: Measure and Mark the Crossmember

- Measure the dimensions of the new oil pan and determine the amount of clearance needed.

- Carefully measure and mark the areas of the crossmember that need to be cut.

- Make sure to leave enough material on the bottom of the crossmember to maintain structural integrity.

Step 3: Cut the Crossmember

- Put on appropriate safety gear, including eye protection and gloves.

- Use an angle grinder, reciprocating saw, or cutting torch to cut along the marked lines.

- Cut out the top, front, and back of the crossmember, leaving the bottom intact.

- Take your time and work carefully to ensure a clean and precise cut.

Step 4: Smooth the Edges

- Once cutting is complete, use a metal file or grinding wheel to smooth any rough edges.

- Remove any burrs or sharp edges that could potentially damage the oil pan or surrounding components.

Step 5: Test Fit the New Oil Pan

- Lower the vehicle and remove the jack stands.

- Temporarily install the new oil pan and check for proper clearance.

- Ensure that the oil pan does not come into contact with the modified crossmember.

Step 6: Finalize the Modification

- If the test fit is successful, reinstall the crossmember and secure it in place.

- You may need to make minor adjustments to the crossmember or oil pan for a perfect fit.

- Consult a professional mechanic if you have any concerns or questions.

Remember to work carefully and safely throughout the process. Always double-check your measurements and clearances to avoid any issues. This modification will allow you to install the new oil pan while maintaining adequate support for the vehicle's structure.

Choosing the Right Non-Stick Pan: A Guide

You may want to see also

You can use a different oil pan that doesn't require notching the crossmember

If you're looking to avoid notching your front crossmember, one option is to use a different oil pan that doesn't require this modification. This can save you time and potential headaches down the road. Here are some suggestions and considerations for choosing an alternative oil pan:

- Holley 302-1 Oil Pan: This pan is designed for LS engine swaps and offers good clearance without the need for notching. It provides ample space between the pan and the crossmember, making it a popular choice for those looking to avoid modifications.

- LH8/H3 Pan: While this pan is marketed as a "swap pan", some users have found that it doesn't offer a significant height difference compared to a truck pan. However, it may still be adequate for your needs, depending on your vehicle's configuration.

- Milodon Oil Pan: If you're working with a Pontiac engine, the Milodon oil pan designed for a '66 389 can be an option. However, be aware that some users have reported a tight fit, and you may need to make slight adjustments for proper clearance.

- Canton Oil Pan: For those with an IAII block, the Canton oil pan has been known to come close to the front main caps. You may need to consider modifications or opt for a different pan to avoid potential issues.

- Swap Pans from Sponsors: If you're open to exploring options, several forum users recommend checking out "true" swap pans available from various sponsors and manufacturers. These pans are specifically designed for engine swaps and may offer better clearance.

When choosing an alternative oil pan, it's essential to consider your vehicle's specific requirements, including engine type, clearance measurements, and the condition of your engine and transmission mounts. Taking the time to research and select the right pan can help you avoid the need for notching your front crossmember. Remember to consult with professionals or experienced enthusiasts if you have any doubts or concerns about the compatibility and installation of a new oil pan.

Oil Pan Compatibility: 350s and Their Oil Pans

You may want to see also

Frequently asked questions

The minimum oil pan clearance for original rubber 5.3L truck mounts is 3/8".

The minimum oil pan clearance for poly mounts is 1/8".

The minimum oil pan clearance for a V8 car is about 1/2".

You should notch the front crossmember by about 8" wide and 4 3/4" long.