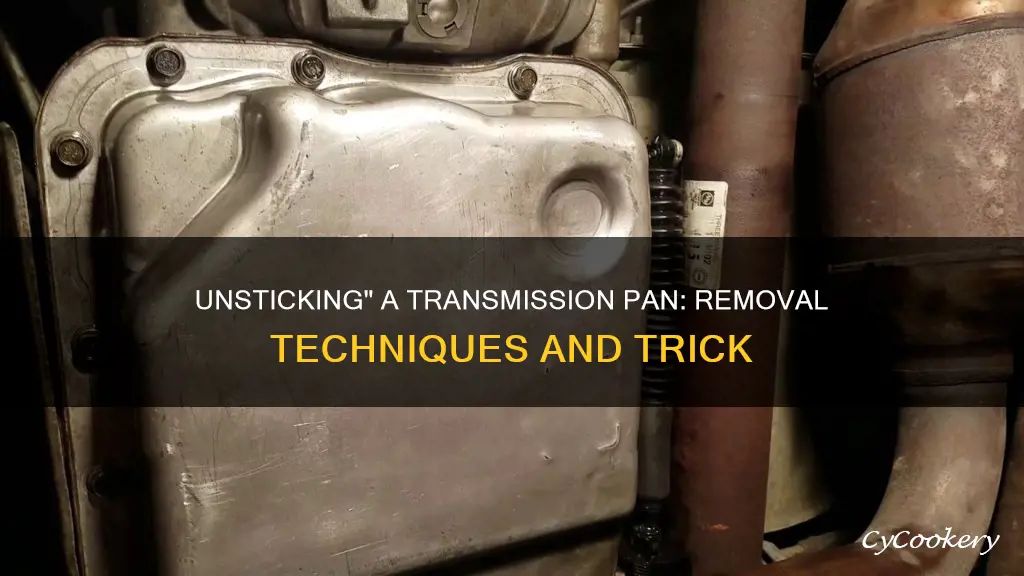

Removing a stuck transmission pan can be a challenging task, but with the right tools and techniques, it is certainly achievable. The first step is to drain the fluid and remove all the bolts, but if the pan is still stuck, more force may be necessary. Some people suggest using a pry bar or a thin, flexible putty knife to gently pry the pan away from the transmission. Others recommend using a screwdriver to penetrate the seam and then lightly prying downward to break the bond. In some cases, a de-greasing chemical or brake cleaner can be sprayed to help loosen the pan. It's important to wear safety glasses and take precautions to avoid any damage to the transmission sealing surface. With patience and the right tools, a stuck transmission pan can be successfully removed.

| Characteristics | Values |

|---|---|

| Reasons for removing the transmission pan | Repair, maintenance, inspection |

| Tools required | Jack, jack stands, drain pan, safety glasses, de-greasing chemical, shop rag, ratchet and socket, flat-head screwdriver, rubber mallet |

| Steps | 1. Raise the front of the vehicle with a jack and support it on jack stands. 2. Locate the transmission pan. 3. Place a drain pan directly under the transmission pan. 4. Put on safety glasses. 5. Spray the base of the transmission and the transmission pan with de-greasing chemical. 6. Wipe the excess grease and debris with a shop rag. 7. Loosen and remove all but two transmission pan bolts. 8. Loosen the two remaining bolts until they are halfway out. 9. Place the head of a flat-head screwdriver into the seam between the pan and the transmission and lightly tap the handle with a rubber mallet. 10. Lightly pry downward to break the bond. 11. Repeat step 9 on each side of the pan until it is free. 12. Allow the transmission fluid to flow into the drain pan, remove the last two bolts, and lower the transmission pan. |

What You'll Learn

- Use a wrench, ratchet, or socket to try and loosen the pan bolt

- Try a penetrating fluid to help loosen the bolt

- Weld a longer bar to the ratchet to increase torque

- Heat the bolt, but be careful of flammable oil

- Use a flat-head screwdriver and a rubber mallet to break the bond between the transmission and pan

Use a wrench, ratchet, or socket to try and loosen the pan bolt

If you're trying to remove a stuck transmission pan, there are a few methods you can try. Firstly, make sure you have the right-sized wrench, ratchet, or socket for the job. In this case, a 6-point wrench or socket is preferable to a 12-point one, as the latter is more likely to slip and strip the bolt head. If you're using a wrench, try hitting the open end with a hammer—this will act like an impact driver on the plug and may help to loosen it.

If you're using a ratchet, you could try welding a long metal tube to the end to increase the torque. Alternatively, you could use a breaker bar, which is a long-handled socket wrench without a ratchet mechanism. This will give you more leverage and allow you to exert more force. You can also try adding a pipe over the handle of your wrench or socket wrench as an extension to increase leverage, but be careful, as cheaper tools could break and cause injury.

If you're still struggling to loosen the pan bolt, you may want to try using a penetrating fluid or lubricant. Apply it to the bolt and threads, covering it completely, and give it some time to work. Try the wrench, ratchet, or socket again, and if the bolt still binds, try rocking it in and out to break the binding force.

As a last resort, you could try heating up the bolt with a small propane torch. Be careful not to melt the bolt, and be aware that this method will ruin the heat treatment on stronger bolts and could damage rubber gaskets or bushings. Once the bolt is hot, remove the heat and let it cool, or speed up the cooling process by pouring warm water over the bolt. Then try the breaker bar again—the heat may have broken the rust seal, allowing the bolt to turn.

Viking Roasting Pans: Where Are They Made?

You may want to see also

Try a penetrating fluid to help loosen the bolt

If you're struggling to remove a stuck transmission pan, one of the best methods to loosen the bolt is to use a penetrating fluid. Penetrating oils are a great way to save time and effort and can make the process of removing bolts a cinch. They are also safer and more effective than using heat.

There are many different types of penetrating oils available, so it's important to choose one that is suitable for your specific application. Here are some factors to consider when selecting a penetrating oil:

- Lubricity and Viscosity: Look for a penetrating oil with a longer-lasting lubricating action if you intend to use it on mechanical parts. Choose a low viscosity product if you need to penetrate tight spaces quickly and deeply.

- Temperature Tolerance: Check the temperature tolerance rating to ensure the oil is suitable for the temperature range you will be working in. Some oils are better suited for high temperatures than others.

- Product Formulation: Consider the ingredients used in the oil and how they may interact with the surfaces you will be applying it to. For example, some oils are safe to use on rubber and plastic parts, while others may damage these materials.

- Non-Foaming or Low Foam: Foaming oils are not suitable for coolant or grinding applications, so opt for a non-foaming or low-foaming formula if you are unsure of how you will be using the oil.

- Environmental Friendliness: Look for products made with eco-friendly ingredients to help conserve the environment and ensure safe use.

- Additives: Different additives in penetrating oils can address specific issues or provide certain benefits. For example, extra pressure additives help prevent wear and tear, while corrosion inhibitors eliminate or prevent corrosion.

- Flash Point: Oils with a higher flash point are less volatile and less likely to combust, so choose accordingly if you are concerned about temperature.

- Kano Aerokroil Penetrating Oil: This is a high-quality oil that is effective at loosening even the toughest rusted bolts. It's easy to use and reduces tension in metal joints while penetrating through rust.

- B’laster Penetrating Catalyst: A well-known product that is effective at loosening rusted or seized fasteners. It creates a non-evaporating film that remains on surfaces longer, providing lubrication for moving parts.

- Liquid Wrench Penetrating Oil: A highly regarded penetrating oil brand known for its unmatched performance in rust removal. It can also be used to lubricate moving parts, free frozen locks, and remove grease from pipes or hoses.

- Gasoila Free All Rust Eater: This penetrant is designed with adaptability in mind and can be used on a variety of metal objects, including hinges, bolts, and gates. It effectively removes rust and frees stuck objects.

- CRC Knock-Er Loose Penetrating Solvent: A powerful solvent that lowers surface tension on rusted or jammed metal items while protecting the metal underneath. It has a very low viscosity, allowing it to penetrate even the tightest spaces.

By using a penetrating fluid, you can increase your chances of successfully loosening the stuck transmission pan bolt without causing damage to the surrounding components.

Domino's Pan Pizza: What Went Wrong?

You may want to see also

Weld a longer bar to the ratchet to increase torque

Welding a longer bar to the ratchet is a possible solution to increase torque when removing a stuck transmission pan. This method can be effective, but it is important to note that applying too much force can damage the transmission pan and surrounding components. Here is a step-by-step guide on how to approach this task:

- Prepare the Work Area: Before beginning any work, ensure you have a clear and safe work area. Place a drain pan under the vehicle to catch any fluids that may leak during the process. It is also recommended to wear safety gear, such as safety glasses, to protect yourself from debris and fluids.

- Locate the Transmission Pan: The transmission pan is typically located at the bottom of the transmission. It is a large, metal pan that holds the transmission fluid.

- Loosen Transmission Pan Bolts: Using a ratchet and socket, loosen all the transmission pan bolts. You may need to apply some penetrative fluid to help loosen them. Leave two bolts halfway out to prevent the pan from falling when it breaks free.

- Weld a Longer Bar to the Ratchet: If you are unable to break the seal with the ratchet, you can try welding a longer bar to the end of the ratchet. This will provide additional leverage and increase the torque applied to the bolts.

- Exercise Caution: When using the welded longer bar, be cautious and apply force gradually. Excessive force can damage the transmission pan, the gasket, or the transmission case.

- Break the Seal: With the longer bar welded to the ratchet, try to break the seal between the transmission pan and the transmission. You may need to work your way around the pan, applying force at different points to loosen it effectively.

- Remove the Transmission Pan: Once the seal is broken, remove the remaining bolts and carefully lower the transmission pan. Be prepared to catch any remaining fluid with the drain pan.

- Clean and Inspect: After removing the pan, clean the transmission and pan thoroughly. Inspect the gasket and pan for any damage. If the gasket is damaged, it will need to be replaced.

- Reinstallation: When reinstalling the transmission pan, follow the manufacturer's torque specifications and bolt tightening pattern. This will ensure an even seal and prevent leaks.

Remember to work carefully and methodically when attempting to remove a stuck transmission pan. Always refer to the vehicle's service manual for specific instructions and torque values relevant to your particular make and model.

Instant Pot Baking: Pan Size Matters

You may want to see also

Heat the bolt, but be careful of flammable oil

Heating the bolt is an effective way to remove a stuck transmission pan, but it should be approached with caution due to the presence of flammable oil. Before attempting this method, ensure that you have tried other recommended approaches, such as using a combination wrench or ratchet and socket to apply torque, or applying penetrating fluid to the bolt.

If these methods do not work, heating the bolt can be considered as a last resort. However, it is important to exercise extreme caution when using heat near flammable oil. The oil in the transmission pan can absorb the heat, and while there may not be enough oxygen for it to burn, there is a risk of scorching the fluid.

To heat the bolt safely, it is recommended to first drain the oil from the pan. Place a drain pan directly under the transmission pan and remove the transmission fluid. This will reduce the risk of fire or scorching the fluid. Once the oil is drained, you can carefully apply heat to the bolt using a blow torch or similar tool. Be sure to wear appropriate safety gear, including safety glasses and heat-resistant gloves, to protect yourself from any potential hazards.

It is important to monitor the temperature and apply heat gradually to avoid damaging the surrounding components. Additionally, have a fire extinguisher nearby as a safety precaution. Once the bolt is heated, you can attempt to loosen it using a wrench or socket. With the combined effect of heat and torque, the bolt should come loose. Remember to work in a well-ventilated area to dissipate any fumes and reduce the risk of fire.

By following these steps and taking the necessary precautions, you can safely remove a stuck transmission pan bolt while minimising the risk associated with flammable oil.

Black Friday: Pots and Pans Deals

You may want to see also

Use a flat-head screwdriver and a rubber mallet to break the bond between the transmission and pan

To break the bond between the transmission and the pan, you will need a flat-head screwdriver and a rubber mallet. First, place the head of the screwdriver horizontally into the seam between the pan and the transmission. Lightly tap the handle of the screwdriver with the rubber mallet until the head of the screwdriver penetrates the seam. Then, gently pry downward to break the bond between the transmission and the pan. You will need to repeat this process on each side of the pan until it is completely free from the transmission.

It is important to note that you should not reuse the transmission fluid in the drain pan, as it may be contaminated by the de-greasing chemical. Additionally, the transmission pan gasket will likely be damaged during this process, so it is recommended to use a new gasket when replacing the pan.

The Comforting World of Hot Pot

You may want to see also

Frequently asked questions

Try using a combination wrench and hit the open end with a hammer.

Try using a breaker bar by welding a long tube to the ratchet.

Drop the oil pan and work on it separately.

Feather the surface with a paint scraper and fill any scratches with JB Weld.

Place a drain pan directly under the transmission pan.