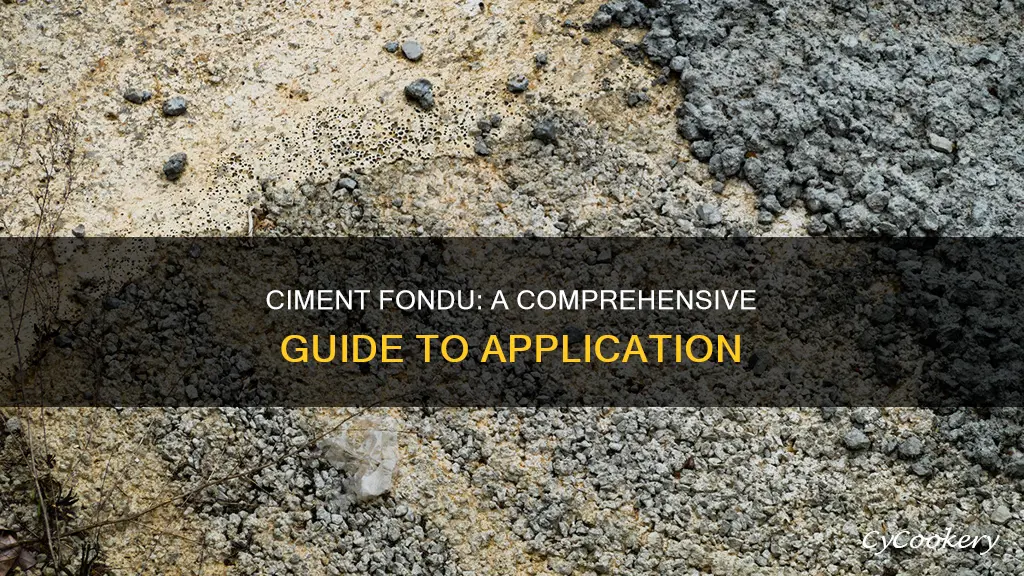

Ciment Fondu is a versatile and resistant hydraulic binder obtained by cooking and milling a mix of limestone and clay. It can be used alone or mixed with other substances. When added to regular specialty binders, Ciment Fondu can accelerate the hardening of concretes and mortars from 3 to 30 minutes, achieving full dryness in just 48 hours. It is ideal for both casting and sculpting and is widely used by sculptors due to its extreme hardness, quick setting, and ability to capture superb detail. It is also suitable for high-temperature applications when used with appropriate refractory aggregates, withstanding temperatures up to 1250°C. In formulated products, it is used as a reagent or as the main binder for products like fast-setting mortar, tile adhesive, and self-levelling products.

What You'll Learn

Ciment fondu is ideal for sculpting and casting

Ciment fondu is a fine, high-alumina casting cement that achieves its full strength in 24 hours and has a working time of approximately 2 hours. It is available in grey, white, and dark brown. The grey is a dark grey/brown colour, while the white is slightly off-white.

When creating a sculpture with ciment fondu, you can mix it with water and sand to achieve the desired consistency. For small sculptures or those that will be kept indoors, you can mix the ciment fondu powder with water to create a creamy slurry. For outdoor use, you can mix 2 parts fine silica sand with 1 part ciment fondu powder, adding enough water to allow you to apply the mixture with a brush.

To create a mould, work on one section at a time and apply the slurry to the mould with a brush, working it into the details and coating the surface evenly to a thickness of about 1.5mm. Then, make the standard ciment fondu mix using 1 part cement fondue, 2 parts sand, and 1 part water. This mixture will be very stiff, but as you apply it to the slurry coat, it will absorb some of the water. Press the ciment into the mould, gradually pushing a wave of slurry in front of it.

To reinforce the cast, create a fondue slurry without sand and paint it onto the layer of pressed ciment. Dip a piece of fibreglass mat into the slurry and work it into the fibres by rubbing it between your fingers. Lay the fibreglass in the mould, continuing to apply small pieces until the entire mould surface is covered. Brush on more slurry to ensure all the fibreglass is lying flat and even, then press a final layer of stiff ciment fondu mix so that the resulting thickness is about 13mm.

Ciment fondu sets by curing rather than drying, so it must be kept wet until it is completely hard. Drying out will prevent proper setting, leaving the ciment weak and crumbly.

Instant Pot Fondue: A Tasty, Quick Treat?

You may want to see also

It can be used for high-temperature applications

Ciment Fondu is a calcium aluminate cement that can be used in high-temperature applications. It is suitable for environments where the cement might be exposed to temperatures of up to 1000°C. This product is ideal when constructing a fireplace or hearth, as it can resist extreme temperatures.

Ciment Fondu is a versatile product with many applications. When used with the correct aggregates, it can withstand very high temperatures. It is a hydraulic binder obtained by cooking and milling a mix of limestone and clay. Its applications include industrial floors, ovens, incinerator walls, and boilers.

When added to regular specialty binders, Ciment Fondu can accelerate the hardening of concretes and mortars from 3 to 30 minutes, allowing a quicker return to operations on small projects. It can be considered fully dry after 48 hours.

Ciment Fondu is also available as a ready-to-use refractory mortar called Fondulit, which is resistant to temperatures up to 1300°C. Fondulit is perfect for assembling and repairing open and closed hearths, barbecues, and refractory brick masonries.

For high-temperature applications, it is important to note that Ciment Fondu should not be mixed with regular cement as it will lose its temperature resistance characteristics. Instead, it should be used with aggregates like crushed firebrick, following the recommended mix of four parts crushed brick to one part Ciment Fondu.

Fondue Pot Health Benefits: What You Need to Know

You may want to see also

It is suitable for construction and industrial applications

Ciment Fondu is suitable for a wide range of construction and industrial applications. It is a versatile and resistant product that can be used alone or mixed with other materials.

In construction, Ciment Fondu is ideal for projects that require a quick turnaround. When used as a single binder, it can be used for concrete that is highly resistant to impacts, temperature variations (as low as -10°C), and various types of corrosion. It is suitable for both indoor and outdoor applications, including industrial floors, shop floors, and decorative wall surfaces.

Ciment Fondu is also commonly used in formulated products in the construction industry, such as fast-setting mortar, tile adhesive, and self-levelling products. It serves as an accelerator for Portland cements in rapid-sealing work and minor repairs.

In industrial applications, Ciment Fondu is well-suited for refractory uses, especially where iron oxide can be tolerated in non-reducing atmospheres. It is also recommended for products that require rapid hardening, resistance to abrasion, mechanical shock, and intermediate temperature exposure.

One of the key advantages of Ciment Fondu is its ability to resist high temperatures. When combined with suitable aggregates, it can withstand temperatures of up to 1,250°C, making it ideal for applications such as industrial furnaces, boilers, and incinerator walls.

Additionally, Ciment Fondu is an excellent choice for projects in aggressive environments due to its resistance to corrosion. It is commonly used in sewage and wastewater systems, seaside projects, and agricultural buildings, where it protects against acid or bacterial attacks.

Overall, Ciment Fondu's unique properties make it a versatile and valuable material for construction and industrial applications, contributing to its reputation as a flagship brand in the industry.

Cutting Bread for Cheese Fondue: A Step-by-Step Guide

You may want to see also

It is a versatile product that can be used alone or mixed

Ciment Fondu is a versatile product that can be used alone or mixed with other materials. When used on its own, it is an excellent hydraulic binder for refractory and specialty concrete applications. It can also be used as an accelerator for Portland cements, reducing the setting time of concretes and mortars from 3 to 30 minutes. This makes it ideal for quick repairs and small projects.

When mixed with aggregates as a single binder, Ciment Fondu concrete becomes highly resistant to impacts, temperature variations (down to -10°C), and various types of corrosion. It is an extremely hard and fast-setting product, achieving its full strength in just 24 hours. This makes it a popular choice for sculptors and large outdoor projects, such as decorative wall surfaces.

For high-temperature applications, Ciment Fondu can be used with refractory aggregates to create mortars and concretes that can withstand temperatures up to 1250°C. This combination is often referred to as \"castable\" and is commonly used for building pizza ovens and other outdoor ovens. The ratio of Ciment Fondu to crushed firebrick or silica sand can vary depending on the specific application and desired properties.

In formulated products, Ciment Fondu is used as a reagent or binder for products such as fast-setting mortar, tile adhesive, and self-levelling products. It is also utilised by tradesmen for rapid-sealing work and minor repairs when mixed with Portland cement. However, it is important to note that mixtures of Ciment Fondu and Portland cement should not be used for structural purposes.

Fondue Filet Mignon: Cooking Time Perfected

You may want to see also

It is a quick-setting cement

Ciment Fondu is a quick-setting cement that can be used for a wide range of applications. It is a hydraulic binder obtained by cooking a mix of limestone and clay, followed by milling. Its quick-setting and rapid-hardening properties make it suitable for various construction and repair projects.

When used as a setting accelerator for Portland cement or specialty binders, Ciment Fondu can reduce the hardening time of concretes and mortars from 30 minutes to as little as 3 minutes. This allows for a quicker return to operations on small projects, with full dryness achieved in just 48 hours.

The rapid setting and hardening properties of Ciment Fondu are particularly advantageous for quick repairs, small masonry work, and road projects. It is also suitable for projects requiring resistance to temperature variations, impact, and corrosion. When mixed with aggregates as a single binder, Ciment Fondu concrete can withstand temperatures as low as -10°C and is highly resistant to various types of corrosion.

It is important to note that Ciment Fondu must be used with aggregates, and the quantity required should be determined based on the information provided by the manufacturer. Additionally, special precautions are necessary when using Ciment Fondu for thin screeds to prevent issues like lack of adherence or cracking due to its rapid hardening properties.

Transforming Fondue into Pencils: A Creative DIY Project

You may want to see also

Frequently asked questions

The ideal ratio is 1:2 of Ciment Fondu to cement sand.

Ciment Fondu achieves its full strength in 24 hours, with a working time of approximately 2 hours.

Ciment Fondu is widely used for casting and sculpting, especially for large outdoor projects. It is also used in formulated products in building chemistry and as an accelerator for Portland cements.