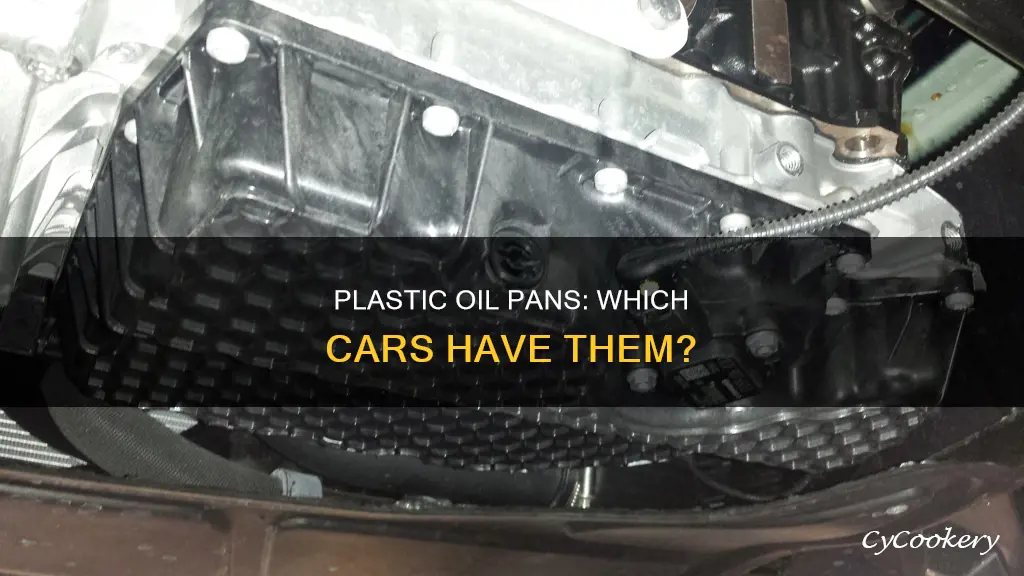

Several car manufacturers have been incorporating plastic oil pans into their vehicles. This includes Ford, BMW, Volkswagen, Audi, and Volvo. While plastic oil pans are designed to be more durable and lightweight than their metal counterparts, they have also been known to cause issues for some car owners. One of the most common problems is leaking, which can occur due to warping of the plastic pan or improper installation of the drain plug. In some cases, car manufacturers have issued technical service bulletins and updates to the replacement procedure to address these issues.

| Characteristics | Values |

|---|---|

| Car Make | Ford, BMW, Volkswagen |

| Car Model | F-150, Edge, Fusion, Lincoln Continental, Lincoln MKZ, Lincoln MKX, Lincoln Nautilus, Police Interceptor Utility, Z4 |

| Engine | 2.7L EcoBoost V6, 3.5L EcoBoost, N20 |

| Year | 2011, 2012, 2015, 2017, 2018 |

| Issues | Leaks, warping, RTV gaskets, drain plug issues |

What You'll Learn

Ford's plastic oil pans are prone to leaking

Plastic oil pans are becoming increasingly common in modern vehicles. While they are more durable than aluminium and steel pans, they are not without their issues. Ford's plastic oil pans, in particular, have been prone to leaking, causing headaches for owners of various models featuring EcoBoost engines.

The problems with Ford's plastic oil pans first surfaced in 2015 when the company introduced the 2.7L EcoBoost V6 engine for its F-150 series of pickup trucks. This engine quickly gained a following, with owners praising its reliability and performance. However, it soon became apparent that the plastic oil pans and oil pan drain plugs were prone to premature leaks. Many new Ford owners reported leaks well before their vehicles reached 20,000 miles, with some even experiencing issues after just 160 miles.

The main reason for these leaks seems to be poor room-temperature vulcanizing (RTV) silicone sealant jobs from the factory. The plastic oil pans can warp, creating gaps between the pan and the engine block. This issue is exacerbated by the shoddy silicone application, leading to repeated leaks even after replacement pans are installed. In response to this widespread problem, Ford has issued multiple technical service bulletins and updated the replacement procedure in some cases.

The design of the plastic oil pan drain plug has also been problematic. The plug features two tabs that lock it into place when hand-tightened. However, installers often mistakenly believe they need to lift or flex these tabs to remove the plug, leading to frequent breakages. Additionally, the plug's silicone O-ring has a limited lifespan when subjected to extreme heat, resulting in leaks if the plug is reused.

While Ford has taken steps to address the leaking oil pan issue, there are still many vehicles on the road that may be affected. This has been an ongoing frustration for Ford owners and service professionals, who must navigate the challenges of proper oil changes and repairs to prevent future problems.

Baking Soda: A Pan Burn Remedy?

You may want to see also

BMW's plastic oil pans can warp

BMWs are known for their use of plastic oil pans, which has surprised many car enthusiasts, with some expressing disbelief that a "premium" car brand would make such a choice. However, BMW is not the only car manufacturer to do so, with Ford and Volkswagen also employing plastic oil pans in some of their models.

Plastic oil pans have become more common in modern vehicles due to advancements in materials science. These pans are made of tough, reinforced plastic that can be more durable and offer better impact resistance than traditional metal pans. They also provide weight reduction and cost savings for manufacturers.

Despite the advantages of plastic oil pans, there are some concerns about their longevity and potential for leaks. Some BMW owners have reported issues with their plastic oil pans warping and no longer sealing properly with the engine block. This can lead to oil leaks, as one owner of a 2012 BMW sDrive28i discovered after a 600-mile trip. The problem was traced to the plastic oil pan, which had warped and no longer sealed correctly. This issue is not unique to BMW, as Ford EcoBoost engines are also known for their plastic oil pans leaking prematurely, sometimes even before reaching 20,000 miles.

The warping of plastic oil pans can be attributed to several factors. One reason is the use of a poor-quality RTV (room temperature vulcanizing) silicone sealant from the factory. When the plastic oil pan warps, it creates gaps between the pan and the engine block, exacerbating the leakage problem. Additionally, plastic oil pans may not be suitable for off-roading or driving on rough terrain as they can be more susceptible to damage from debris and impacts compared to metal pans.

To address the issue of leaking plastic oil pans, some manufacturers have made changes to their designs and replacement procedures. For example, Ford revised the design of its 2.7L oil pan in the 2018 model year, and in 2019, they issued technical service bulletins for 2.7L and 3.0L EcoBoost vehicles, recommending the use of a press-in-place gasket instead of the RTV silicone gasket.

While plastic oil pans offer benefits in terms of weight reduction and cost savings, they may require more careful handling and maintenance to prevent leaks. It is essential for car owners and service professionals to be aware of the specific characteristics and requirements of these pans to ensure proper care and avoid potential issues.

Easy Steps to Eliminate Tabbed Pan Border Issues

You may want to see also

Plastic oil pans are more durable than aluminium

Plastic oil pans are becoming increasingly common in modern vehicles. While some people are sceptical about their durability, they offer several advantages over aluminium pans. Firstly, plastic oil pans are more durable than aluminium in terms of corrosion resistance. Unlike aluminium, plastic pans do not rust, which can be a common issue with metal pans. This makes plastic a more suitable material for oil pans, as they are constantly exposed to oil and other fluids.

Another advantage of plastic oil pans is their weight. Plastic pans are significantly lighter than aluminium ones, which can contribute to improved fuel efficiency in vehicles. Additionally, plastic oil pans are often cheaper to manufacture than aluminium pans, making them a cost-effective option for automakers.

While some people have expressed concerns about the durability of plastic oil pans, these concerns are often unfounded. Plastic oil pans are designed to be strong and durable, with some users reporting no issues even after years of use. The type of plastic used is crucial, as different types have varying levels of durability. For example, glass-filled nylon is known for its toughness and impact resistance. However, it's important to note that all materials, including aluminium, have their limitations, and the choice of material depends on the specific application and requirements.

One potential downside of plastic oil pans is their heat resistance. Plastic pans may not be able to withstand extremely high temperatures like aluminium pans. However, this is usually not an issue for typical drivers, as engine temperatures are carefully monitored and regulated to prevent overheating.

In conclusion, plastic oil pans offer several advantages over aluminium pans, including corrosion resistance, lightweight construction, and cost-effectiveness. While there may be some concerns about their heat resistance, modern plastics are designed to be durable and can withstand the normal operating temperatures of most vehicles. Therefore, plastic oil pans are a viable and reliable option for automakers and drivers alike.

Hot Pot, Warm Home: Using Your Hot Pot as a Space Heater

You may want to see also

Plastic oil pans are cost-saving

The use of plastic oil pans in automobiles has been a growing trend, with companies like Ford, Cummins, Detroit, Volkswagen, and Audi adopting their use. While some people express concerns about the durability and longevity of plastic oil pans, advancements in materials science have led to the development of strong and durable plastics that can withstand the demands of automotive applications. For example, glass-filled nylon is known for its toughness, and composite materials can be engineered to offer cost-cutting solutions without compromising strength and durability.

One notable advantage of plastic oil pans is their resistance to rust and corrosion. Metal oil pans, particularly those made of steel or aluminium, are susceptible to rusting over time, especially in harsh environments or with exposure to road salts. Plastic oil pans, on the other hand, do not rust, eliminating the need for frequent replacements due to corrosion. This not only reduces maintenance costs for vehicle owners but also contributes to a more sustainable and environmentally friendly automotive industry by reducing the need for frequent oil pan replacements.

The weight savings offered by plastic oil pans are also significant. Injection-molded plastic pans can provide weight savings of around 40%, which contributes to improved fuel efficiency. Lighter vehicles require less fuel to operate, leading to cost savings for vehicle owners at the pump. Additionally, automakers can benefit from improved fuel economy ratings, which can enhance their brand image and attract environmentally conscious consumers.

Furthermore, plastic oil pans offer design flexibility and ease of manufacturing. The use of plastic allows for more intricate and innovative designs, such as the waffle-design ribbing pattern developed by Ford, which can enhance the impact resistance of the oil pan. Plastic oil pans can also be designed with features that make maintenance and repairs more accessible, such as easy-to-use drain plugs that do not require tools for removal. This not only reduces the time and effort required for oil changes but also makes the process more convenient for vehicle owners and mechanics alike.

In conclusion, plastic oil pans offer cost savings in various ways. From reduced manufacturing costs to improved fuel efficiency and rust resistance, plastic oil pans present a compelling case for their adoption in the automotive industry. While some concerns about durability persist, advancements in materials science continue to enhance the performance and longevity of plastic oil pans, making them a viable and cost-effective solution for automakers and consumers alike.

Lid Size for 8.5-inch Pan

You may want to see also

Plastic oil pans are lighter than metal pans

Plastic oil pans are becoming more common in newer vehicles. They are lighter than metal pans, and therefore help to reduce the overall weight of the vehicle. This, in turn, helps to improve fuel efficiency.

For example, the plastic oil pans in some newer Ford vehicles are said to be 41% lighter than their metallic predecessors. This is a significant weight reduction, and it contributes to better gas mileage.

In addition to being lighter, plastic oil pans also offer other advantages. For instance, they are often reinforced with composite materials, making them quite strong and durable. They are also less susceptible to rust and corrosion than metal pans.

However, some people have expressed concerns about the use of plastic oil pans. One concern is that plastic may not be able to withstand high temperatures or constant heating and cooling cycles without becoming brittle over time. There are also worries about the potential for plastic pans to crack or shatter upon impact, although reinforced plastic pans are designed to withstand such forces.

Despite these concerns, the use of plastic oil pans is likely to continue, as manufacturers strive to reduce vehicle weight and improve fuel efficiency.

Comet Cleaner: The Secret Weapon for Removing Stubborn, Baked-On Food from Your Pans

You may want to see also

Frequently asked questions

Ford, BMW, Volkswagen, and Audi are known to have used plastic oil pans in some of their models.

Plastic oil pans are used to reduce weight and increase gas mileage. They are also cost-effective for manufacturers.

Plastic oil pans are generally considered durable and can withstand light impacts better than aluminium pans. However, they may become brittle over time due to heat cycles and are more prone to leaking.

Plastic oil pans are more durable than aluminium and steel oil pans, as they do not rust and are less likely to deform or bend. They are also easier to work with and often do not require tools for maintenance.