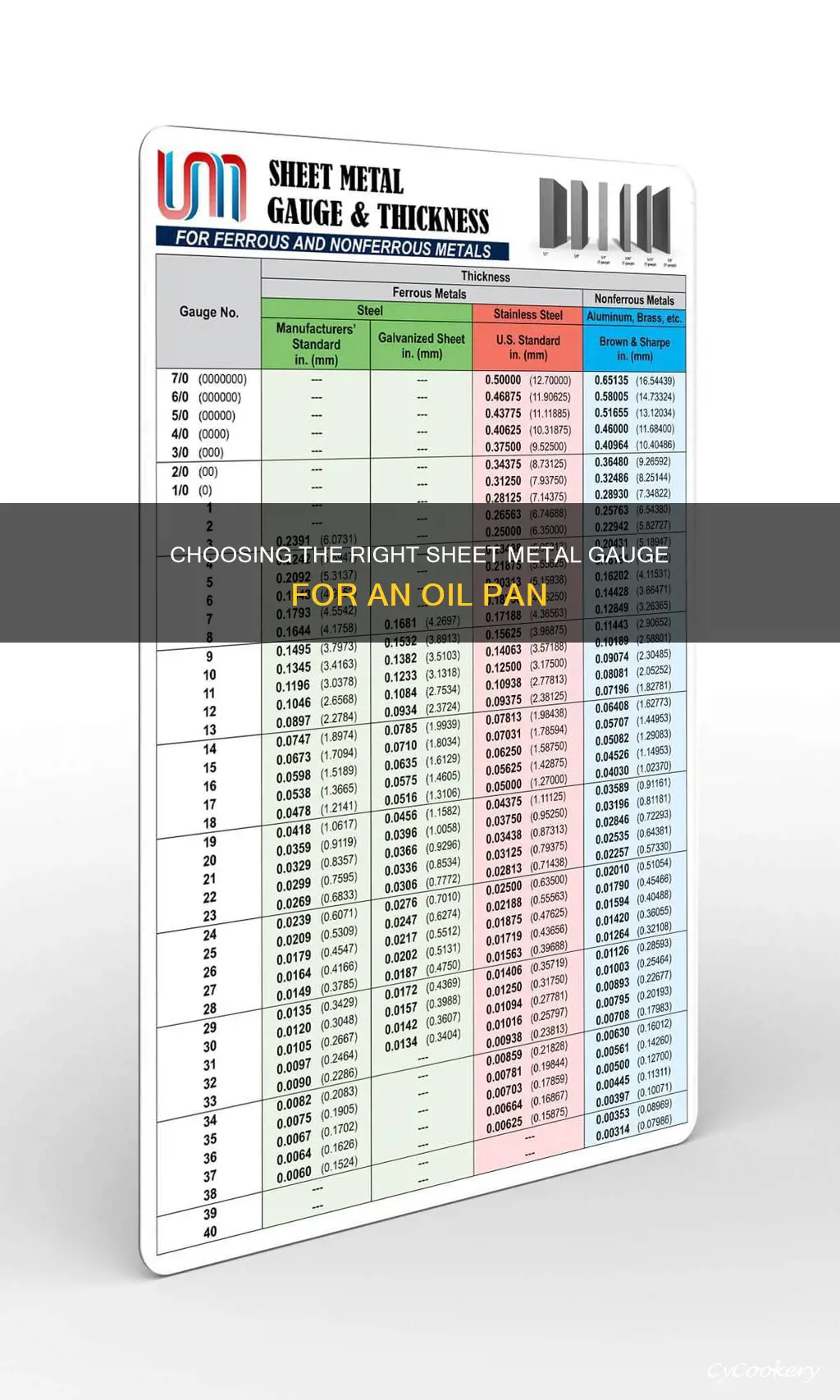

When it comes to choosing the right gauge sheet metal for an oil pan, there are a few factors to consider. The most important consideration is the thickness of the metal, which is determined by the gauge number. A higher gauge number indicates a thicker and heavier sheet metal. For oil pans, it is generally recommended to use a heavier gauge to prevent warping and leakage. Additionally, the intended use of the oil pan also plays a role in the decision-making process. For example, if the oil pan is for a high-performance vehicle that will be subjected to extreme conditions, a thicker gauge metal would be more suitable to withstand the additional stress.

| Characteristics | Values |

|---|---|

| Sheet metal gauge for oil pan | 16, 18, or 22 |

| Material | Steel or aluminium |

What You'll Learn

22-gauge sheet metal is too flimsy for an oil pan

22-gauge sheet metal is not suitable for an oil pan due to its flimsy nature. While it may be suitable for some applications, such as auto and RV repairs or industrial repairs, it lacks the required strength and durability for an oil pan.

An oil pan needs to be made of a thicker, more robust material to withstand the demands of the engine. The oil pan is responsible for holding the engine's oil, which is crucial for lubrication and cooling. It is subjected to high temperatures, vibrations, and, in some cases, impact forces. As such, the material used for the oil pan must be strong enough to withstand these conditions without failing.

DusterDave, a user on the Moparts Forums, has stated that 22-gauge sheet metal is "pretty flimsy" based on their experience designing HVAC equipment out of steel sheet metal. They recommend using 18-gauge or 16-gauge sheet metal for an oil pan, which has a thicker composition and can better withstand the stresses of the application.

Another user on the same forum, MR_P_BODY, suggests that the thickness of the material should be considered when forming the corners of the oil pan. Bending the sheet metal will reduce its thickness in those areas, so starting with a thicker gauge is advisable to ensure the oil pan has sufficient strength.

Additionally, the choice of material for the oil pan is crucial. Steel and aluminium are commonly used, each with its own advantages and disadvantages. Steel is strong and durable but prone to corrosion, while aluminium is lightweight and has excellent heat conduction but may not have the same strength as steel. The specific type of material and its thickness will depend on the engine application and the intended use of the vehicle.

In conclusion, 22-gauge sheet metal is not an appropriate choice for an oil pan due to its lack of strength and durability. Thicker gauges, such as 18-gauge or 16-gauge, are more suitable for this application, ensuring the oil pan can withstand the rigours of the engine and provide reliable performance.

Removing Oil Burn Marks: Restoring Your Pan's Glory

You may want to see also

16-gauge sheet metal is a good choice for an oil pan

When it comes to choosing the right sheet metal for an oil pan, gauge and thickness are crucial factors to consider. While some may opt for thinner options like 22-gauge or 18-gauge metal, 16-gauge sheet metal stands out as the superior choice for several compelling reasons.

Firstly, 16-gauge sheet metal offers exceptional durability. With a thickness of .059, it is significantly sturdier than 22-gauge metal, which is relatively flimsy at .028 thick. This added durability is essential for oil pans, which are susceptible to damage from impacts and deformation during use. By choosing 16-gauge metal, you're investing in a more robust solution that can withstand the rigours of racing or everyday driving conditions.

The thickness of 16-gauge sheet metal also provides a practical advantage when it comes to modifications and repairs. During the modification process, bending and shaping the metal can result in a slight reduction in thickness at the corners. Starting with a thicker gauge helps ensure that your oil pan retains sufficient material strength even after fabrication. Additionally, thicker metal is less prone to warping from high temperatures and sudden temperature changes, making it a safer and more reliable option for oil pans.

Another benefit of 16-gauge sheet metal is its versatility. It strikes the perfect balance between thickness and workability. While it is substantial enough to provide the required strength, it is not so thick as to become unwieldy or difficult to work with. This makes it an excellent choice for both professional fabricators and DIY enthusiasts alike. Whether you're crafting a custom oil pan from scratch or repairing a damaged one, 16-gauge sheet metal offers the flexibility and ease of use you need to get the job done right.

Furthermore, 16-gauge sheet metal is widely available and commonly used in various applications. This means that finding replacement parts or additional materials for future modifications will be more accessible and convenient. Standardisation also ensures that your oil pan will be compatible with a broader range of vehicles and engine setups.

Lastly, 16-gauge sheet metal provides added peace of mind when it comes to safety. Thicker metal offers improved impact resistance, reducing the likelihood of tears or punctures in the event of a collision or debris strike. This not only helps protect your vehicle but also enhances the overall safety of you and your passengers.

In conclusion, 16-gauge sheet metal is the optimal choice for fabricating or repairing an oil pan. It offers a combination of durability, versatility, and safety that thinner gauges struggle to match. By selecting 16-gauge metal, you're ensuring that your oil pan will be robust, reliable, and capable of withstanding the demands of modern driving conditions.

Residence Inn: Pots and Pans Available?

You may want to see also

18-gauge sheet metal is also a good choice

When it comes to choosing the right gauge sheet metal for an oil pan, there are a few options to consider. While some people may recommend using 22-gauge sheet metal, this option tends to be flimsy and not ideal for an oil pan. A better choice would be 18-gauge sheet metal, which offers a good balance between thickness and weight.

With a thickness of about .045, 18-gauge sheet metal provides a sturdy option that is still relatively easy to work with. It is worth noting that some people may prefer to use thicker options, such as 16-gauge or even boiler plate, especially if the oil pan is expected to withstand significant impact or pressure. However, for most applications, 18-gauge sheet metal will get the job done.

The benefits of choosing 18-gauge sheet metal for an oil pan are twofold. Firstly, it offers increased durability over thinner options, providing a stronger barrier to protect the oil pan from damage. Secondly, the slightly thicker material can help to improve the overall structural integrity of the oil pan, reducing the chances of warping or bending over time.

Additionally, 18-gauge sheet metal is widely available and often used in various applications, making it a cost-effective choice. It is also worth noting that, when compared to thicker options, 18-gauge sheet metal may be easier to work with, especially when it comes to bending or shaping the material to fit the contours of the oil pan.

Overall, while there are several factors to consider when choosing the right gauge sheet metal for an oil pan, 18-gauge is a good middle-ground option that offers durability, ease of use, and cost-effectiveness. It strikes a balance between thickness and weight, making it a versatile choice for a variety of oil pan applications.

Preventing Pie Crust Sticking: Tips and Tricks

You may want to see also

Original oil pan material is usually around .035 gauge

The original oil pan material is usually around 0.035 gauge. This thickness is commonly used for steel pans, while aluminium pans are typically made from slightly thicker material, around 0.045 gauge.

When modifying an oil pan, it is recommended to use the same or similar thickness material as the original pan. This ensures that the pan maintains its structural integrity and can withstand the demands of the application. Using a thinner material may result in reduced strength and durability, while a thicker material may affect the pan's performance and functionality.

The gauge of the sheet metal used for an oil pan is important as it needs to be strong enough to withstand the forces and temperatures it will be subjected to. A thicker gauge metal will be more durable but will also be heavier, which can impact the overall weight of the vehicle. On the other hand, a thinner gauge metal may be more prone to deformation or damage.

Additionally, the design of the oil pan can also affect the choice of sheet metal gauge. For example, if the pan has bends or corners, a thicker material may be required to maintain its shape. The intended use of the vehicle should also be considered, as vehicles that undergo wheelstands or other extreme conditions may require a thicker gauge oil pan to withstand the additional stresses.

Transmission Oil Pan: Change Frequency and Best Practices

You may want to see also

For aluminium pans, .045 gauge is a good thickness

When it comes to oil pans, the gauge of sheet metal you choose is important. The gauge of a metal sheet refers to its thickness, with lower gauge numbers indicating thicker sheets and higher gauge numbers indicating thinner sheets. While the gauge doesn't correspond to standard measurements like inches or millimetres, it's still an important factor to consider when selecting sheet metal for any project.

For aluminium oil pans, a thickness of .045 gauge is recommended by some fabricators. This thickness strikes a good balance between durability and weight, ensuring the pan can withstand the demands of racing or street use while also being light enough to not weigh down the vehicle.

It's worth noting that the gauge of sheet metal can vary depending on the type of metal. For example, a sheet of 30-gauge standard steel is thicker than a sheet of 30-gauge aluminium. So, when selecting sheet metal for an oil pan, it's important to consider not only the gauge but also the type of metal that best suits your needs.

Additionally, the intended use of the oil pan can also influence the ideal gauge. If the pan is for a vehicle that frequently drags or performs wheelies, a thicker gauge may be preferable to withstand the impact of these activities. On the other hand, if weight is a primary concern, a thinner gauge may be more suitable.

In conclusion, for aluminium oil pans, a thickness of .045 gauge is a good choice as it offers a balance of durability and weight. However, it's important to consider the specific requirements of your project, including the type of metal and intended use, when selecting the appropriate gauge of sheet metal.

The Perils of Pot-Hot Plate Contact: Understanding the Hazards

You may want to see also

Frequently asked questions

16-gauge sheet metal is ideal for a steel oil pan as it is thick and durable.

No, 22-gauge sheet metal is too flimsy for an oil pan.

18-gauge sheet metal is a good alternative as it is thicker than 22-gauge and provides better durability.

Yes, thicker sheet metal is generally more durable and resistant to warping.