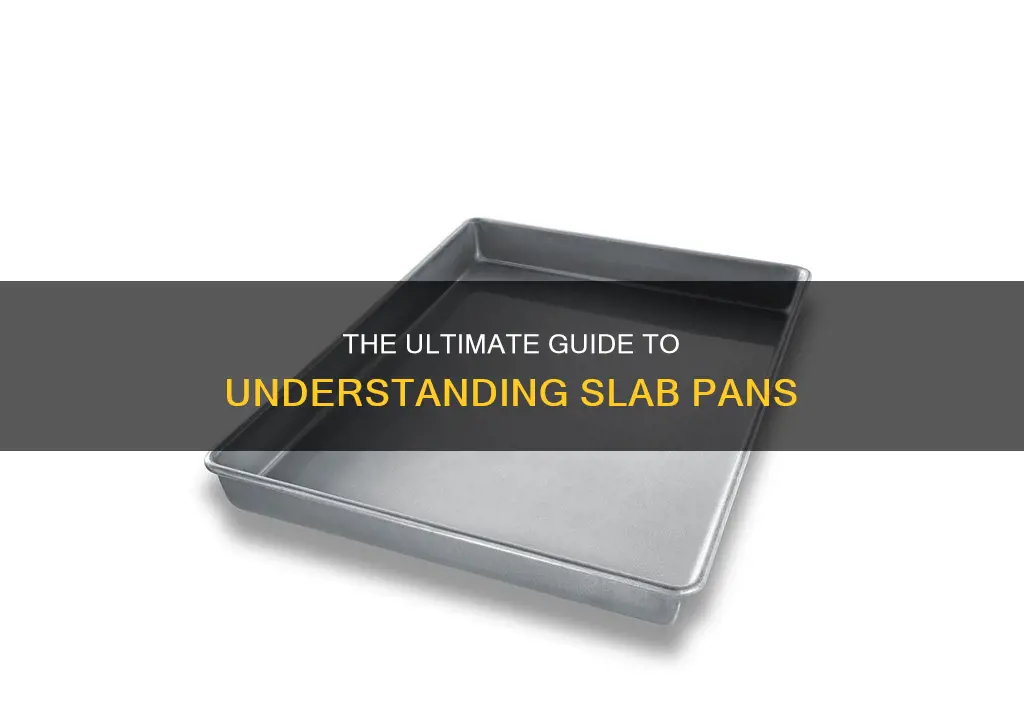

A slab pan is a broad category that refers to the use of a corrugated metal pan to form a slab of concrete. It is a cost-effective solution for structures with high live loads and long-span requirements, commonly used in buildings such as hospitals, laboratories, and offices. In the context of baking, a slab pan, also known as a baking slab or jelly roll pan, is a type of bakeware made of materials like porcelain or ceramic. It is larger than a standard baking sheet, measuring around 15x10x1 inches, and is known for its conductivity, getting hot quickly and evenly.

What You'll Learn

- Pan slab construction is a cost-effective solution for buildings like hospitals and offices

- Metal pan deck is a slang term for metal floor decking

- A baking slab is a dish-sheet pan hybrid

- Pan slab construction accommodates penetrations and future repurposing

- A slab pie pan can be made from porcelain, ceramic, or metal

Pan slab construction is a cost-effective solution for buildings like hospitals and offices

Pan slab construction is an effective way to reduce costs when building structures with high live loads and long-span requirements, such as hospitals and offices. This construction method has evolved significantly over the years, and today, it offers a range of benefits that enhance the value of the building and its marketability.

One of the key advantages of pan slab construction is the use of reusable steel pan forms, which provide a cost-effective solution for long-span structural concrete designs. These steel pans have also increased in width over time, with standard widths now ranging from 53 to 112 inches, while their depths remain at 16, 20, or 24 inches. This allows for longer structural spans and higher design loads, resulting in reduced costs for perimeter glazing and other skin materials.

Additionally, pan slab construction offers a more efficient use of space, requiring less building volume for heating and cooling. It also facilitates easy integration of mechanical and electrical systems, enhancing the building's overall functionality. Furthermore, the steel pans provide lateral stability, contributing to the structure's stability and safety.

Another benefit of pan slab construction is its fire resistance. The steel pans are inherently fire-resistant, providing a highly fire-rated structure without incurring additional costs for fire retardant treatments. This enhances the safety of the building and reduces potential fire hazards.

In conclusion, pan slab construction offers a cost-effective solution for buildings like hospitals and offices by utilising reusable steel pan forms, increasing structural efficiency, and providing inherent fire resistance. The method's evolution has resulted in wider pan widths, longer structural spans, and a range of advantages that enhance the building's overall value and functionality.

Panara Pickup: Receipt Printing Essential?

You may want to see also

Metal pan deck is a slang term for metal floor decking

A slab pan, or baking slab, is a ceramic or porcelain pan used for baking. It is ideal for slab pies, flatbreads like focaccia, and cookies.

Metal Pan Deck: A Slang Term for Metal Floor Decking

Pan decking is a corrugated sheet metal designed to have structural concrete poured over it. It is a stay-in-place form that supports the concrete while it cures. Pan decking was used from the 1940s to the 1960s but is no longer manufactured. Today, the term is used as a generic term for metal floor decking.

There are two main types of metal decking: structural metal roof decking and composite floor decking. Metal decking has a high strength-to-weight ratio, making it ideal for multi-story buildings. It is also inexpensive, lightweight, and easy to install.

When specifying metal decking, it is important to determine the type, depth, gauge, and finish required. The type of decking will depend on the intended use, while the depth will determine the strength of the panel. The gauge and finish will depend on the specific requirements of the job.

Reseasoning a White Ceramic Green Pan

You may want to see also

A baking slab is a dish-sheet pan hybrid

One of the key advantages of a baking slab is its ability to conduct and retain heat. Made from materials like porcelain or French porcelain, this pan gets hot quickly and evenly, ensuring a consistent bake. The thermal shock resistance of the baking slab is also noteworthy, preventing cracking or warping when exposed to extreme temperature changes.

The baking slab is an excellent choice for creating beautiful and delicious crusts on pies, pastries, and bread. Its size and shape make it perfect for slab pies, giving them a crisp and golden finish. For bread lovers, the baking slab produces a super tender inside and a perfectly golden and crispy crust.

While the baking slab is a fantastic addition to any avid baker's kitchen, it may not be a necessity for casual bakers. Its large size and specialty in pies, pastries, and bread make it less ideal for those who prefer simpler bakes like cookies or brownies. Additionally, the baking slab's price point of $99 may be a consideration for some, as it is an investment piece for those passionate about baking.

Overall, the baking slab is a unique and functional piece of bakeware that can elevate your baking experience, especially if you enjoy creating pies, pastries, and bread. Its heat retention, thermal shock resistance, and ability to produce perfect crusts make it a worthwhile addition to your collection of baking essentials.

Removing Pizza Pan Rust from Ceramic Countertops

You may want to see also

Pan slab construction accommodates penetrations and future repurposing

A pan slab, also known as a pan deck, is a broad category term for a metal floor decking system. It involves the use of corrugated metal pans to form slabs of concrete, creating a suspended slab. While the term is widely used, there is no specific product called a "pan deck", and it is instead considered a category of decking.

Pan slab construction has evolved to offer cost-effective solutions for buildings with high live loads and long-span requirements. This method is particularly useful for structures such as hospitals, laboratories, and offices. One of the key advantages of pan slab construction is its ability to accommodate penetrations and future repurposing.

The use of reusable steel pan forms allows for longer spans and higher design loads. Individual pans can reach lengths of 20 to 30 feet, enhancing productivity and reducing costs. Joist spans of 30 to 60 feet are common, along with live loads of 50 to 100 psf. This flexibility in design enables easy integration of mechanical and electrical systems, making it ideal for a variety of building types.

Additionally, pan slab construction offers a highly fire-rated solution without incurring additional costs for fire retardant treatments. The steel pans act as a structural solution, providing stability and supporting the concrete slab. With advancements in technology, pan slab construction has become a viable option for designers and builders, offering a cost-effective and efficient method for creating long-span structures.

Effective Ways to Clean Your Porridge Pan at Home

You may want to see also

A slab pie pan can be made from porcelain, ceramic, or metal

A slab pie pan is a must-have for bakers. It is a pan that combines a baking dish and a sheet pan. Typically, a slab pie pan has one-inch sides and is also referred to as a "jelly roll pan".

Cleaning Caraway Cookware: Tips for Sparkling Pots and Pans

You may want to see also

Frequently asked questions

A slab pan is a pan used to form a slab of concrete. It is a corrugated metal pan that can be made from galvanized steel.

A slab pan is used to form wet concrete to create a suspended slab. It is also known as pan decking and is used in the construction of buildings such as hospitals, laboratories, and offices.

Using slab pans in construction offers several advantages, including reduced project costs, longer structural spans, enhanced fire rating, improved comfort due to reduced vibrations and sound, and easy integration of mechanical and electrical systems.