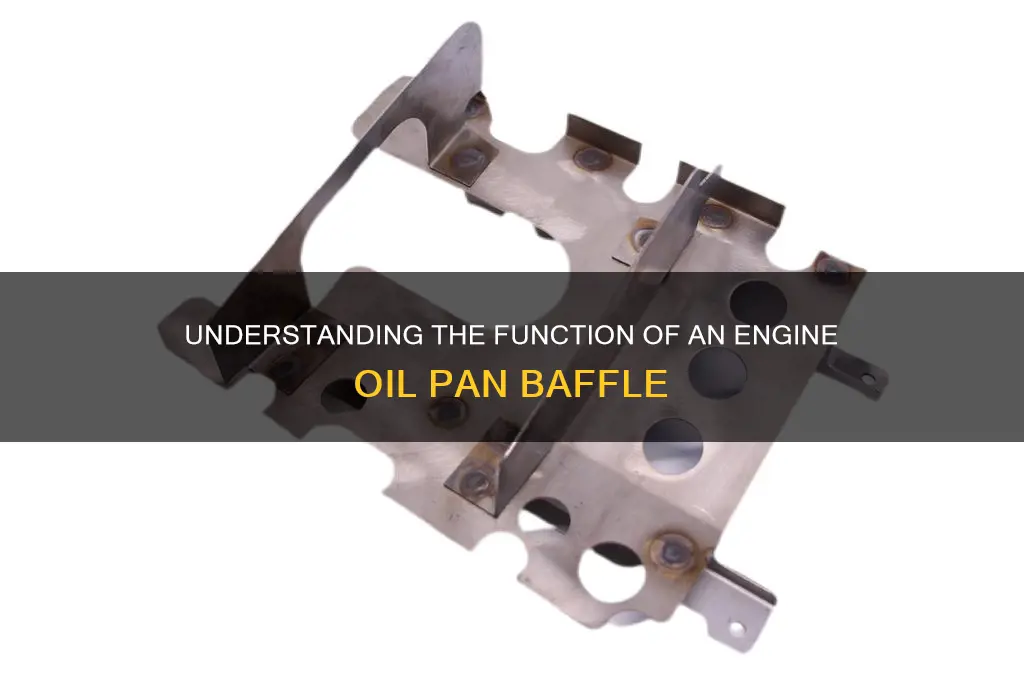

An engine oil pan baffle is a device used to control the movement of oil in an engine's oil pan, also known as a sump. During high-performance driving, oil can slosh around, leading to oil starvation and potential engine damage. An oil pan baffle helps to direct oil towards the oil pickup, ensuring adequate lubrication of critical engine components. This is particularly important in motorsports where high g-forces are experienced for extended periods. While a dry sump system is commonly used in racing, a more affordable alternative is to use a baffled oil pan, which can be purchased or fabricated at home.

What You'll Learn

How an engine oil pan baffle prevents oil starvation

An engine oil pan baffle is a simple and cost-effective way to prevent oil starvation in an engine. Oil starvation occurs when the oil in the oil pan sloshes or climbs up the inside walls of the pan during hard cornering, braking, or acceleration, causing air to get sucked into the oil pump instead of oil. This interruption in continuous oil lubrication can lead to excessive engine wear and even catastrophic engine failure.

The engine oil pan baffle addresses this issue by creating chambers within the oil pan that restrict the movement of oil. These chambers are designed to make it easy for oil to flow towards the oil pickup while making it difficult for the oil to slosh away from the pickup. By effectively boxing in the area surrounding the oil pump inlet, the baffle creates a sump within a sump, ensuring that there is always enough oil present to prevent oil starvation.

Additionally, the baffle may also increase the capacity of the oil pan, providing more oil available in the system. This further reduces the risk of oil starvation and helps maintain critical engine lubrication. The baffle also features one-way trap doors that allow oil to flow into the sump area but make it difficult for oil to exit, especially under high g-loads.

The use of an engine oil pan baffle is particularly important in motorsports where the car and engine are subjected to high g-forces for extended periods of time. In such conditions, a standard wet sump system may not be adequate to prevent oil starvation. By installing an engine oil pan baffle, the risk of oil starvation is reduced, helping to improve engine performance and prevent engine failure.

Panning for Gold in Florida: Is It Possible?

You may want to see also

Baffle design and fabrication

Baffles are flow-directing or obstructing vanes or panels used to direct the flow of a liquid or gas. They are used in some household stoves and in some industrial process vessels (tanks), such as shell and tube heat exchangers, chemical reactors, and static mixers.

The design and fabrication of baffles involve several considerations and steps:

Design Considerations:

- Flow Direction: Baffles are designed to direct or obstruct the flow of a liquid or gas in a specific way. This may involve changing the direction of flow, preventing swirling or vortex formation, or controlling the velocity of the fluid.

- Tube Support: In heat exchangers, baffles are used to support tube bundles and prevent sagging during production and operation.

- Steam Starvation Prevention: Baffles help prevent steam starvation, which becomes more critical with increased fluid velocity and the length of the exchanger.

- Heat Transfer Efficiency: In static mixers and chemical reactors, baffles increase fluid velocity, promote mixing, and enhance heat transfer efficiency.

Fabrication Steps:

- Baffle Type and Orientation: Determine the type of baffle required (e.g., longitudinal flow baffles, impingement baffles, support/blanking baffles) and their orientation (horizontal or vertical) based on the specific application and design requirements.

- Spacing and Placement: Ensure correct spacing and placement of baffles during installation. The minimum baffle spacing is typically governed by standards, such as those set by the Tubular Exchanger Manufacturers Association (TEMA). The maximum spacing depends on the material and size of the tubes.

- Recirculation Zones: Avoid creating recirculation zones or dead spots during design and installation, as these areas can reduce the effectiveness of heat transfer.

- Customisation: In some cases, custom baffle designs may be required to meet specific performance or space constraints. This may involve collaboration between engineers and fabricators to balance performance requirements and fabrication limitations.

Panado While Breastfeeding: Safe or Not?

You may want to see also

How to tackle oil slosh

Oil slosh is a common problem in performance street machines. It can be caused by high-performance driving conditions, such as hard braking, acceleration, or cornering. During these manoeuvres, oil can slosh around the bottom end of the engine, leading to oil starvation and potential bearing damage. Here are some ways to tackle oil slosh:

Use an Oil Pan Baffle

One way to tackle oil slosh is to use an oil pan baffle. A baffle helps to control the movement of oil within the pan, keeping it close to the oil pickup and preventing it from sloshing up out of the pan. Baffles can be purchased aftermarket or designed and fabricated at home. When installing a baffle, ensure that it is sealed properly to the oil pan to prevent leaks.

Optimise Oil Pickup Location

The placement of the oil pickup is crucial in preventing oil slosh. It should be positioned in the middle of the oil pan to ensure adequate oil supply during various driving conditions.

Use an Accusump

An Accusump is an accumulator that stores a volume of oil under pressure. It fills up when the engine is started and releases the stored oil when the engine experiences oil starvation, helping to maintain constant lubrication.

Implement Crank Scrapers and Windage Trays

Crank scrapers and windage trays can help to control oil splashing and reduce the amount of oil that is thrown around the engine compartment. However, their effectiveness depends on the geometry of the engine casings.

Modify the Oil Pan Design

The design of the oil pan can be optimised to reduce oil slosh. This can include adding horizontal sheets or baffles to direct oil flow and prevent it from sloshing up the sides of the crankcase.

Use Commercially Available Solutions

For some engines, such as the small-block Chevy, there are a wide range of aftermarket pans available that are designed to improve oil control. These pans can be a good option if you are unsure about designing and fabricating your own solution.

Grease-Free Pans: Wash Tricks

You may want to see also

Advantages of a dry sump system

A dry sump system offers several advantages over a wet sump system. Firstly, it can hold more oil in an extra reservoir, making it better for sustained cornering as the engine is less likely to starve of oil. This also means that the engine can be mounted lower, improving the centre of gravity and enhancing vehicle handling and stability.

Secondly, the oil capacity of a dry sump system can be increased by using a large external reservoir, which would be impractical in a wet sump system. This also allows for improved oil temperature control as the oil is stored away from the hot engine, and the increased volume of oil provides resistance to heat saturation.

Thirdly, a dry sump system improves oil quality. In a wet sump system, oil can become aerated and frothy as it sloshes around, reducing its effectiveness as a lubricant. A dry sump system minimises aeration and more effectively de-aerates oil by pumping it into a remote reservoir.

Finally, a dry sump system increases engine power. In a wet sump system, oil can cause substantial viscous drag, leading to power loss. By removing oil from the crankcase, a dry sump system eliminates this drag, resulting in increased power and improved efficiency.

Cubans' Creative Cookware Shopping

You may want to see also

The importance of lubrication under high-performance driving conditions

Lubrication is an essential, yet often overlooked, aspect of car mechanics. It is the unseen hero that allows for the smooth roar of an engine and the quiet whirl of gears. Under high-performance driving conditions, the importance of lubrication becomes even more critical.

High-performance driving places greater demands on the engine and transmission system, requiring optimised lubrication methods and compositions. The main goals of lubrication are to reduce friction, increase efficiency, and decrease wear on interacting surfaces, thereby improving durability. In the context of high-performance driving, proper lubrication can help prevent excessive wear and catastrophic engine failure.

One of the challenges of lubrication under high-performance conditions is the high g-forces experienced during extended periods of high-speed cornering or racing. In normal production cars with a "wet sump" system, the oil can slosh to one side of the oil pan, away from the oil pump pickup, leading to oil starvation and potential engine damage. This issue is commonly addressed in motorsports by employing a dry sump system, where oil is sucked out of a shallow pan and stored in an external reservoir. While effective, this system can be expensive and out of reach for most weekend racers.

A more affordable alternative is to use a baffled oil pan. Baffles within the oil pan create chambers that restrict the oil's movement, making it easier for the oil to travel towards the pickup while limiting its ability to slosh away. Baffled oil pans also tend to increase the capacity of the oil pan, ensuring a more abundant oil supply for the engine. This simple and cost-effective solution helps ensure adequate lubrication even under the high g-forces of high-performance driving, reducing the risk of engine damage and improving performance.

In conclusion, proper lubrication is critical under high-performance driving conditions. By reducing friction, increasing efficiency, and preventing excessive wear, optimised lubrication methods and compositions contribute to the overall performance and longevity of the vehicle. Baffled oil pans, in particular, offer a cost-effective solution to the challenges of oil starvation in high g-force situations, making them a popular choice for those seeking to push their vehicles to the limit.

Spraying Tin Foil Pans: To Spray or Not to Spray?

You may want to see also

Frequently asked questions

An engine oil pan baffle is a device used to control the movement of oil in the oil pan of an engine, preventing it from sloshing around during high-performance driving conditions such as hard braking, acceleration, or cornering.

An engine oil pan baffle helps to maintain constant lubrication under high-performance driving conditions. Without a baffle, the oil can slosh away from the oil pump pickup, leading to oil starvation and potentially catastrophic engine failure.

There are two main types of engine oil pan baffles: trap-door baffles and horizontal baffles. Trap-door baffles use small doors that only open inward, allowing oil to enter the chamber but not exit. Horizontal baffles, on the other hand, use sheets of metal with holes to direct the flow of oil toward the pickup.

The type of engine oil pan baffle you need will depend on the specific requirements of your vehicle. If you are primarily concerned with keeping the oil near the pickup, a trap-door baffle may be the best option. If you want to prevent oil from sloshing up into the cylinder head, a horizontal baffle might be more suitable.

Yes, it is possible to make your own engine oil pan baffle. This typically involves using spare metal sheets to create a baffle that fits your oil pan. However, it is important to ensure that the design and installation are done correctly to avoid compromising the lubrication system.