When installing a 200-amp sub-panel, it is crucial to select the appropriate wire size to ensure optimal performance and safety. The National Electrical Code (NEC) specifies a minimum requirement of 2/0 AWG for copper wire or 4/0 AWG for aluminum or copper-clad wire. However, opinions vary, with some sources recommending 3/0 AWG copper wire or even larger sizes for longer distances to compensate for voltage drop. Aluminum wiring is a popular choice due to its cost-effectiveness and ease of installation, while copper offers superior conductivity and resistance to heat and corrosion.

| Characteristics | Values |

|---|---|

| Wire size for 200 amp service | 3/0 AWG copper wire or 4/0 AWG aluminum wire |

| Allowable ampacity of 3/0 copper wire | 225 Amp |

| Allowable ampacity of 4/0 aluminum wire | 205 Amp |

| Minimum size for grounding conductors (copper) | 4 AWG |

| Minimum size for grounding conductors (aluminum or copper-clad) | 2 AWG |

| Wire size for 200-amp service (distance > 100 feet) | 4/0 AWG copper wire or 250 MCM aluminum wire |

| Wire size for 200-amp service (distance > 150 feet) | 250 MCM copper wire or 350 MCM aluminum wire |

| Cable type | THHN/THWN Wire, Service Entrance SER Cable, Underground Service Entrance (USE-2) Cable |

| Minimum conduit size for wire | 1.5 inches |

| Minimum conduit size for three wires | 2 to 2.5 inches |

| Grounding wire size (copper) | 4 AWG |

| Grounding wire size (aluminum) | 2 AWG |

What You'll Learn

Copper vs aluminium wire

Copper and aluminium are the two most common types of metal conductors used in electrical wires. They are efficient, easy to use, and affordable. However, there are advantages and disadvantages to both types of wiring.

Copper wiring is the traditional preference due to its strength, durability, and superior conductivity. It is also more flexible, making it a priority when wiring needs to handle large loads of electricity. Copper has a higher ampacity, meaning it can carry a higher current without overheating. It is also more versatile, recyclable, and requires less maintenance. However, copper is much more expensive, heavier, and more susceptible to theft. It also requires more support over long distances.

Aluminium wiring is a more affordable, lightweight, and flexible option. It is safe when properly installed and saves a lot of money, especially in commercial buildings. However, aluminium has a lower current carrying capacity and greater resistance than copper, requiring a larger cross-sectional area. It is also more difficult to work with, prone to cracking and failure when subjected to vibration, and more susceptible to corrosion. Additionally, aluminium is difficult to solder and requires a larger raceway.

When deciding between copper and aluminium wire, cost is a significant factor. The price of copper has been surging, with the average price of electric copper wire increasing by over 120% between January 2021 and January 2022. As a result, many electrical engineers are turning to aluminium as a substitute.

For a 200-amp sub-panel, the recommended wire size is 4/0 AWG for aluminium or aluminium copper-clad wire, and 3/0 AWG for copper wire. The allowable ampacity for 3/0 copper wire is 225 amps, while for 4/0 aluminium wire, it is 205 amps. If you plan to run cables for long distances, you should also accommodate a voltage drop, which may require upsizing the wire size.

Pizza Pans: To Wash or Not?

You may want to see also

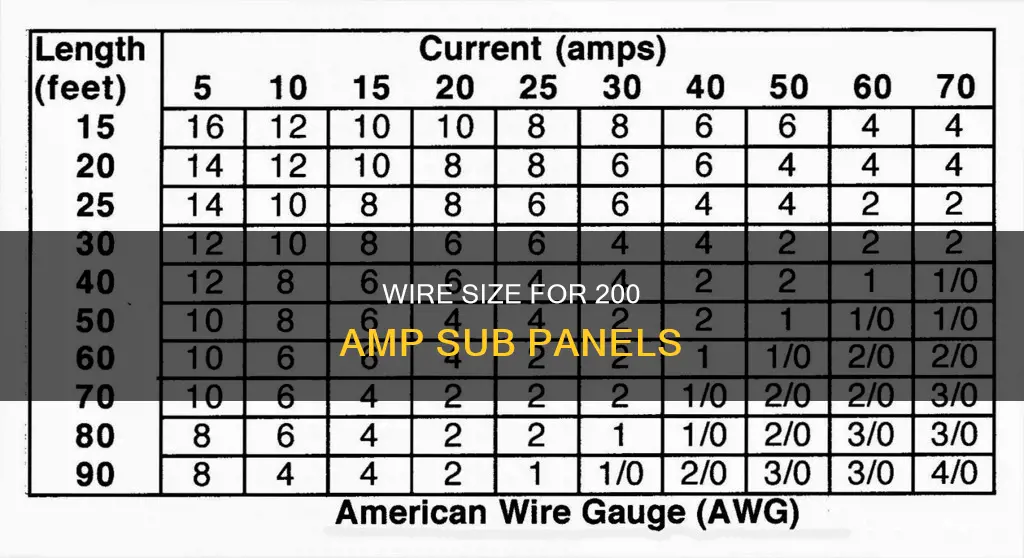

Wire length

The length of wire you will need for your 200-amp sub-panel depends on the distance between the main panel and the sub-panel. If the distance is relatively short (under 50 feet), you can use copper, aluminum, or copper-clad wires. For longer distances (over 100 feet), it is recommended to use a higher-gauge copper wire to minimise voltage drop.

- For a 100-foot distance, you may need to use 4/0 AWG copper wire or 250 MCM aluminium wire.

- For distances over 150 feet, use 250 MCM copper wire or 350 MCM aluminium wire.

- If you are connecting a sub-panel that is 140 feet away, you can consider using THHN SER for the indoor portion and URD for the outdoor section. However, this setup may not comply with local electrical codes, so it is important to consult an electrician or relevant guidelines.

- If you are connecting a sub-panel within a short distance (around 6 feet), you can use #4/0 aluminium or copper-clad aluminium wire.

It is important to note that the wire length recommendations may vary depending on local electrical codes, the specific application, and other factors. Always consult a certified electrician or relevant guidelines before starting any electrical work.

Pork Loin Pan Bone: What You Need to Know

You may want to see also

Voltage drop

When installing wires, voltage drop is an important factor to consider. Voltage drop refers to the loss of voltage as electricity travels through a wire. This can be influenced by factors such as the length of the wire, the type of wire used, and the amount of current flowing through it.

For a 200-amp sub-panel, ensuring minimal voltage drop is crucial to maintain the performance and longevity of electrical equipment. While the acceptable voltage drop limit can vary, a common standard is to keep the voltage drop below 3%. This means that for every 100 feet of wire, the voltage drop should not exceed 3 volts.

To achieve this, the wire size and material become critical. For copper wires, a 3/0 AWG or larger is recommended to minimise voltage drop. For aluminium or aluminium-copper clad wires, a 4/0 AWG or larger is typically required.

It's worth noting that voltage drop calculations should be based on actual load rather than the "breaker trip value". Additionally, while voltage drop is not a code issue, it is essential to ensure that electrical equipment operates within its specified voltage range as per manufacturer guidelines.

In summary, when selecting wires for a 200-amp sub-panel, choosing the appropriate wire size and material is vital to minimise voltage drop and ensure optimal performance and safety of electrical equipment.

Pan Size for 2-Quart Capacity

You may want to see also

Cable type

When it comes to cable type, both copper and aluminium cables can be used for a 200-amp sub-panel, as long as size requirements are met.

Copper cables

Copper cables are a popular choice for 200-amp services. The minimum size for copper grounding conductors is 4 AWG, and the allowable ampacity of 3/0 copper wire is 225 amps. 2/0 AWG copper wire can also be used, but its ampacity is lower at 195-200 amps, which will put it at maximum load.

Aluminium cables

Aluminium cables are another option and are often cheaper than copper. The minimum size for aluminium grounding conductors is 2 AWG. The allowable ampacity of 4/0 aluminium wire is 205 amps, and it is important to note that aluminium is susceptible to corrosion and requires an antioxidant like nolox.

Copper-clad aluminium cables

Copper-clad aluminium wire is also an option and can provide the benefits of both copper and aluminium.

Popular cable types

Some popular cable types for 200-amp services include:

- Service Entrance (SER) Cable: SER cables are acceptable in both copper and aluminium and are used to connect the electric meter to the main service panel.

- THHN/THWN Wire: 200-amp services allow for THHN/THWN wire in both copper and aluminium. These individual conductors can be used inside a conduit for service entrance applications.

- Underground Service Entrance (USE-2) Cable: This type of cable is designed for direct burial and is used when the service entrance conductors run underground from the electric meter to the main service panel.

It is important to note that the size of the wire and the amperage of the breaker are critical factors when wiring a 200-amp sub-panel, and it is always best to consult with a certified electrician and follow local electrical codes and standards.

Sill Pan Slope: Why It's Essential

You may want to see also

Grounding

When installing a 200-amp sub-panel, it is important to ensure proper grounding for safety and to meet electrical code requirements. Grounding is a critical component of any electrical installation, as it helps prevent electrical shocks, reduces the risk of fire, and protects sensitive equipment from damage. Here are some detailed instructions and considerations for grounding a 200-amp sub-panel:

Understanding Grounding

The size of the grounding conductor is crucial to ensure adequate grounding. For a 200-amp sub-panel, the minimum size for the grounding conductor is 4 AWG (American Wire Gauge) for copper conductors and 2 AWG for aluminum or aluminum-copper clad conductors. These sizes are specified to handle the high current and provide a robust ground path.

To accommodate the large grounding conductors, a grounding bar must be installed inside the sub-panel enclosure. This bar provides a secure point of connection for the grounding wires. For a 200-amp sub-panel, a ground bar kit such as the PK18GTAL or PK23GTAL is commonly used. These kits include a ground bar with a 4/0 lug, which is suitable for connecting the large grounding wires.

Isolating Ground from Neutral

It is important to isolate the ground from the neutral in a 200-amp sub-panel installation. This requires removing the green bonding screw from the mains section of the panel. By isolating the ground and neutral, you ensure that the grounding system operates effectively and that the neutral bar is not overloaded.

If the ground lug included with the ground bar kit is not the correct size for your grounding wire, there are alternative options. You can purchase a bare lug made specifically for 4/0 wire and bolt it directly to the interior of the sub-panel. Alternatively, you can splice the 4/0 wire down to a smaller size (#4 aluminum or #6 copper) and then connect it to the ground bar.

Considerations for Feeder Circuits

It is important to note that the rules for grounding may vary depending on whether the sub-panel is fed from a larger service or is a standalone installation. If the sub-panel is fed from a larger service, the grounding wire size may be limited to the size of the service wire. In such cases, a 4/0 wire is typically allowed for a 200-amp feeder, but it is important to ensure that the load does not exceed 180 amps.

In summary, proper grounding is a critical aspect of installing a 200-amp sub-panel. By following the recommended conductor sizes, installing a suitable ground bar, and ensuring proper isolation of ground and neutral, you can achieve a safe and code-compliant electrical installation.

Little Caesars Personal Pan Pizza: Available?

You may want to see also

Frequently asked questions

The recommended wire size is 3/0 AWG copper wire or 4/0 AWG aluminum or aluminum-copper-clad wire.

The allowable ampacity of 3/0 copper wire is 225 Amp, while the allowable ampacity of 4/0 aluminum wire is 205 Amp.

The minimum wire size for a grounding conductor is 4 AWG for copper and 2 AWG for aluminum or aluminum-copper-clad conductors.

For longer distances, the wire size should be increased to accommodate voltage drop. For every 100 feet, the wire size should be increased by 20%.

Copper wires are more costly but have benefits like corrosion and heat resistance, and high conductivity. Aluminum wires are cost-effective, lightweight, and good conductors but have less longevity than copper.