The oil pan check valve on an LS engine should be removed when plugging off the oil bypass check valve to keep unfiltered oil out of the engine. The factory bypass check valve can allow unfiltered oil to enter the engine's bearings and lifters. This can be prevented by replacing the factory check valve with a billet aluminium bypass delete valve.

| Characteristics | Values |

|---|---|

| When to remove the oil pan check valve | When the secondary pressure relief valve gets stuck, causing oil pressure issues |

| When to remove the oil pan check valve | When Active Fuel Management (AFM) and Variable Valve Timing (VVT) have been deleted |

| When to remove the oil pan check valve | When the oil pump has been swapped to a standard volume oil pump |

| When not to remove the oil pan check valve | When using a high-volume pump |

| When not to remove the oil pan check valve | When using AFM/DOD engines |

What You'll Learn

Oil bypass check valve delete

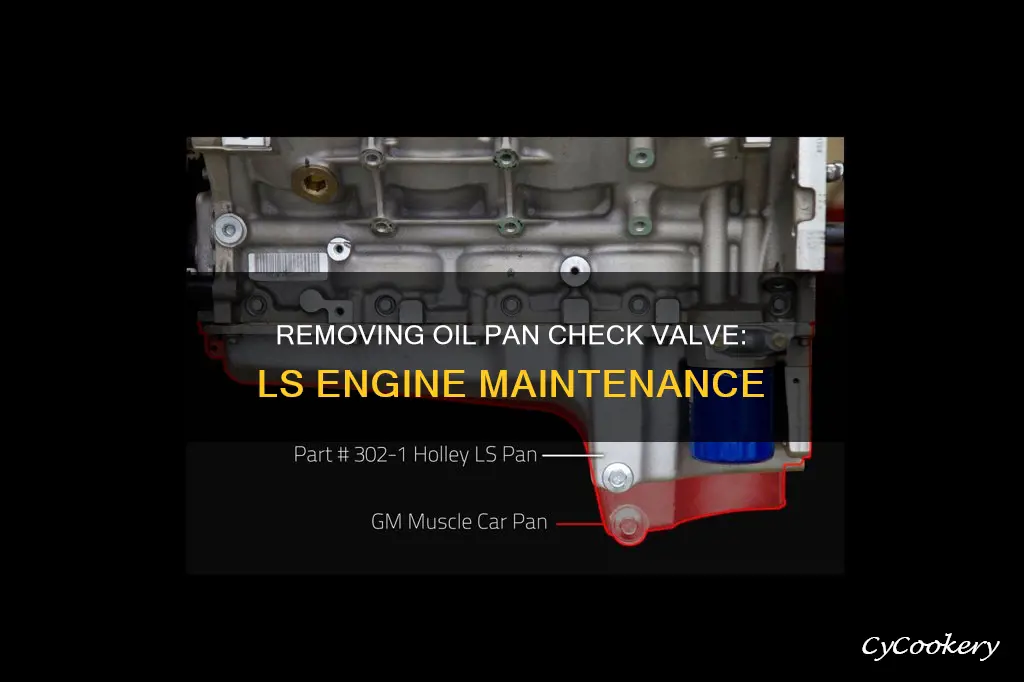

The oil bypass check valve delete is a modification for certain GM Gen III and IV LS engines. It involves replacing the factory oil bypass check valve with a billet aluminium plug, which prevents unfiltered oil from entering the engine.

The factory bypass check valve is a safety feature designed to allow oil to bypass the filter in the event that it becomes blocked, preventing oil starvation. However, this can result in unfiltered oil entering the engine's bearings and lifters, which can cause damage over time.

The bypass check valve delete is recommended for engines that have had Active Fuel Management (AFM) and Variable Valve Timing (VVT) disabled and have been fitted with a standard volume oil pump. It is not recommended for engines with a high-volume oil pump, as this can result in excessive oil pressure.

The process of performing the bypass check valve delete involves removing the old valve, which can sometimes be difficult, and installing the new plug with a new O-ring. The plug is designed to be easily removable if necessary, by screwing in a bolt and pulling it out.

This modification is relatively inexpensive and can provide improved protection for the engine, ensuring that only filtered oil reaches the bearings and lifters. However, it is important to note that it is not compatible with all engines, and it should be confirmed that the bypass valve is located in the filter adapter housing, not the oil pan, before proceeding with the modification.

Removing the Washer Pan: A Step-by-Step Guide

You may want to see also

Oil pan pressure relief valve plug

The LS Oil Pan Pressure Relief Valve Plug Kit is used to delete the secondary pressure relief valve in some LS oil pans. This valve is used to bypass excess oil pumped out by the high-volume oil pump when Active Fuel Management (AFM) and Variable Valve Timing (VVT) are inactive.

The secondary pressure relief valve can sometimes get stuck, causing oil pressure issues. It may be deleted if the AFM and VVT have been deleted and the oil pump has been swapped to a standard volume oil pump. However, removing this valve is not recommended for engines with a high-volume pump. In such cases, the high-volume pump must be replaced with a Melling M295, 10295, 10296, or a similar pump to safely eliminate the pressure relief valve in the oil pan.

The plug kit comes with an M14x1.5 plug and a crush washer to ensure a proper seal. It is compatible with certain LS-based vehicles such as the 4th Gen Pontiac GTO, Pontiac G8, and 5th Gen Camaro.

It is important to note that there is a separate LS Gen 3 & 4 Oil Bypass Check Valve Delete product that is specifically for use with the bypass valve located in the oil filter adapter housing and is not compatible with the oil pan delete.

Domino's Pan Pizza: Deep Dish or Not?

You may want to see also

Active Fuel Management (AFM) and Variable Valve Timing (VVT)

The oil pan check valve on an LS engine should be removed when it is stuck, causing oil pressure issues. This is often the case when Active Fuel Management (AFM) and Variable Valve Timing (VVT) have been deleted, and the oil pump has been swapped to a standard volume oil pump.

When deleting AFM and VVT from an engine, it is important to consider the potential impact on engine performance and fuel efficiency. Deleting these systems may result in increased fuel consumption and a reduction in the engine's ability to adapt to different driving conditions. Therefore, it is crucial to carefully evaluate the benefits and drawbacks before proceeding with any modifications.

Several kits are available on the market that can be used to delete AFM and VVT from specific Chevrolet engines, such as the L99, LS3, and L76 L77. These kits typically include camshafts, valve spring kits, pushrods, lifters, head gaskets, head bolts, crankshaft bolts, camshaft gears, and timing covers. It is important to note that deleting AFM and VVT may require custom tuning, and it is always recommended to seek professional assistance when performing such modifications.

Get the Mordhau Pan: Quick and Easy Guide

You may want to see also

High-volume oil pump

However, for stock or mildly-tuned engines with tighter clearances, a standard oil pump is typically sufficient. Using a high-volume oil pump in such cases may result in higher oil pressure but not necessarily more oil flow. This is because oil will not flow where it is not needed, and the increased pressure could lead to unnecessary load on the distributor and cam gears.

For LS engines, the decision to remove the oil pan check valve is influenced by the type of oil pump in use. If the engine has a high-volume oil pump, removing the check valve is generally not recommended. To safely eliminate the check valve, the high-volume pump must be replaced with a standard volume pump, such as the Melling M295, 10295, or 10296.

Melling, a leader in oil pump engineering, offers high-volume oil pumps that increase oil flow by approximately 20%. These pumps are engineered to the highest standards, utilising the latest gear and gerotor technology. The precision-machined gears ensure proper engine pressure and efficient pump operation, while the ground end plates offer maximum wear resistance. Each Melling high-volume oil pump is individually tested under conditions simulating actual engine operation.

Removing Oil Pan: Necessary or Not?

You may want to see also

Oil filter bypass

An oil filter bypass valve is a crucial component of an oil filter, ensuring the continuous flow of oil to the engine in all conditions. While the oil filter's primary function is to remove contaminants from the oil, the bypass valve comes into play when the filter gets clogged or when the oil pump sends more oil than the filter can handle.

Under normal circumstances, oil flows through the filter, which effectively cleans it by trapping and holding contaminants until the next oil change. However, during cold starts or when the engine is operating at high speeds, the oil filter may not be able to fully meet the engine's lubrication demands. This is where the oil filter bypass valve comes into play.

The bypass valve allows oil to bypass the filter partially, ensuring sufficient oil flow to the engine. This unfiltered oil, while not ideal, is still better than no oil at all, as a lack of lubrication can cause extensive and costly engine damage. Additionally, if the filter becomes clogged, a pressure spring inside the oil filter activates the bypass valve, allowing oil to pass through without any filtration.

It is important to note that the bypass valve only opens when there is a significant pressure differential between the inlet and outlet of the filter. This prevents the engine from starving for oil, which could occur if the filter becomes completely clogged.

In terms of the LS engine, the topic of removing the oil pan check valve is briefly mentioned in the context of certain LS-based vehicles. These vehicles feature an M14x1.5 pressure relief valve inside the oil pan, which is used to bypass excess oil pumped by the high-volume oil pump. In some cases, this secondary pressure relief valve can get stuck, causing oil pressure issues. While removing this valve is generally not recommended, it may be deleted if Active Fuel Management (AFM) and Variable Valve Timing (VVT) have been disabled and a standard volume oil pump has been installed.

Wontons Sticking to the Pan? Try This

You may want to see also

Frequently asked questions

An oil pan check valve is a safety feature that lets unfiltered oil into a engine's bearings and lifters in case the oil filter is restricted or never changed.

The oil pan check valve should be removed when there is a need to replace it with a new one or when upgrading to a bypass delete.

A bypass delete is a plug that replaces the oil pan check valve, preventing unfiltered oil from getting into the engine.

A bypass delete should be installed when the factory check valve is opening with oil pressure surges, letting unfiltered oil into the bearings.

If your engine is experiencing oil pressure issues, it is recommended to check if the secondary pressure relief valve is stuck and needs to be deleted.