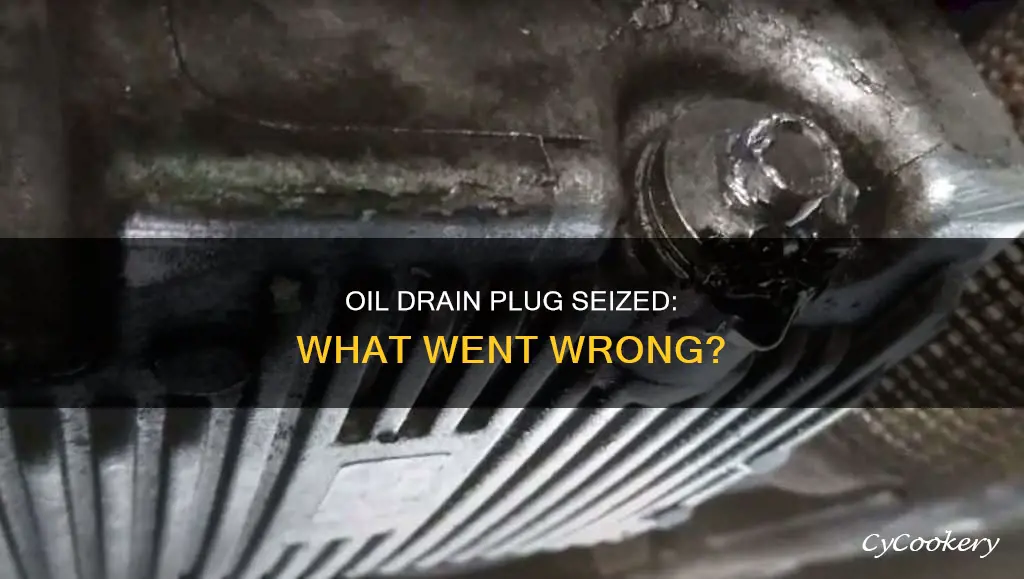

The oil drain plug is a threaded bolt made from soft metal, such as aluminium, that is tightened to the bottom or side of the engine oil pan. Over the years, auto manufacturers have transitioned from steel to lightweight aluminium oil pans, and this has resulted in an increase in stripped oil drain plugs. The oil drain plug can get damaged through either cross-threading or over-tightening, which ruins the structure and spacing of the threads on the pan, bolt, or both. Cross-threading occurs when the plug is not installed straight and is forced the rest of the way, while over-tightening happens when a power tool is used and exerts too much force to screw the plug into place.

| Characteristics | Values |

|---|---|

| Oil drain plug material | Soft metal (e.g. aluminum) |

| Oil pan material | Aluminum |

| Cause of oil drain plug seizing | Cross-threading, overtightening, use of power tools, incorrect wrench/socket size |

| Solutions | Use vice grip pliers, flathead screwdriver, bolt extractor, heat, thread chaser tool, replace oil pan |

What You'll Learn

- Cross-threading and over-tightening can ruin the structure and spacing of threads on the pan, bolt, or both

- Oil drain plugs are made from soft metals like aluminium, which can strip easily if not handled carefully

- Using a conventional thread chaser or Heli-Coil can result in aluminium shavings getting into the crankcase and oil pan

- A stripped drain plug can be removed by rotating it counter-clockwise with a wrench or socket wrench

- A rounded-off head drain plug requires a specialty socket called a bolt extractor

Cross-threading and over-tightening can ruin the structure and spacing of threads on the pan, bolt, or both

Cross-threading and over-tightening can permanently damage the threading on the oil pan, bolt, or both. Cross-threading occurs when a threaded connection is made at an angle, rather than straight on. This can happen when the external and internal threads are incompatible, when a user makes an improper connection, or when foreign material such as dirt or rust sits between the individual threads. When cross-threading occurs, the threads of the screw do not match up with those of the nut or threaded hole, resulting in jamming or damage. This is more common in smaller screw sizes, particularly in finer threads. Over-tightening a bolt can also damage the threads, as oil drain plugs are typically made from soft metals such as aluminium, which can be easily stripped.

When threads are damaged, oil will leak, which can cause engine problems and allow contaminants to enter the underside of the engine oil pan. If the threads on the oil drain plug or pan become stripped, or if the gasket breaks, the entire oil pan may need to be replaced. This is a complex task, especially if it involves removing a frame crossmember.

To avoid cross-threading and over-tightening, it is important to refer to the service manual for the recommended torque required to loosen and tighten the plug. Using the correct torque can help prevent damage to the threads. Additionally, starting to tighten the bolt by hand can help ensure that the connection is straight and reduce the risk of cross-threading.

Makeup Geek Pan Sizes Revealed

You may want to see also

Oil drain plugs are made from soft metals like aluminium, which can strip easily if not handled carefully

Oil drain plugs are typically made from soft metals like aluminium, which can strip easily if not handled carefully. This is why it is important to use the correct tools and techniques when removing and replacing them.

Oil drain plugs are threaded bolts that seal the opening in the engine oil pan, preventing oil from leaking out. The softness of the metal used in these plugs means that they can be easily damaged if excessive force is applied or if the wrong tools are used. Stripping the threads on the plug or pan can result in oil leaks, which can cause engine problems and contamination.

When removing an oil drain plug, it is crucial to use the correct socket size and type. A six-point socket is generally recommended over a twelve-point socket to avoid slipping and potentially damaging the plug. Additionally, it is important to apply the appropriate amount of torque when loosening and tightening the plug to avoid cross-threading or over-tightening.

In some cases, oil drain plugs may become extremely tight, making them challenging to remove. In such situations, it is essential to use proper techniques to increase leverage, such as using a breaker bar, a longer handle or pipe attached to the wrench, or linking two wrenches together. It is also advisable to have an extra set of hands to tap on the back of the ratchet while turning.

Furthermore, it is recommended to replace the oil drain plug gasket periodically, as it can deform over time. The gasket helps create a tight seal between the plug and the oil pan, preventing leaks. Copper, aluminium, rubber, or nylon gaskets are commonly used and can be replaced with traditional-style plugs or cold-welded brass engine oil drainback valves.

Overall, it is important to handle oil drain plugs with care due to the softness of the metal they are made of. By using the correct tools, applying the right amount of torque, and replacing gaskets as needed, you can help prevent stripping and ensure a proper seal for your engine oil pan.

Pan-Seared Filet: No Oven, No Problem

You may want to see also

Using a conventional thread chaser or Heli-Coil can result in aluminium shavings getting into the crankcase and oil pan

Oil drain plugs are threaded bolts usually made from soft metals such as aluminium. They are tightened to the bottom or side of the engine oil pan. It is easy to destroy the threads on the plug or pan by applying too much torque with a slightly off-kilter bolt.

When the threads on the plug or pan become stripped, or the gasket breaks, oil will leak. This can eventually cause engine problems, allow contaminants to enter the underside of the engine oil pan and create messy garage floors.

There are alternative solutions to this problem. One option is to use a compression plug that deforms a rubber gasket to seal off the drain hole. However, this is only a temporary fix. Another option is to replace the entire oil pan, although this is a more complex job, especially if it involves removing a frame crossmember.

It is also possible to create a new opening in the pan using a tap and die set, then insert a new plug and gasket. The old opening will need to be sealed with a self-expanding universal rubberised oil drain plug. If the pan is showing signs of wear, or the leaking oil drain plug cannot be removed, installing a new engine oil pan may be the best solution.

Pot-Scorched Stone: The Heat Threshold of Granite Countertops

You may want to see also

A stripped drain plug can be removed by rotating it counter-clockwise with a wrench or socket wrench

An oil drain plug can seize in an oil pan for several reasons, including overtightening, incorrect torque, or using the wrong tool. To remove a stripped drain plug, you will need to apply more force in the counter-clockwise direction to loosen it. Here are some methods to achieve this:

Using a Wrench or Socket Wrench

- Using a wrench or socket wrench, apply force in the counter-clockwise direction. You can try a six-point impact socket, which provides a better grip and is less likely to slip.

- For more leverage, use a longer handle or attach a pipe over the handle of the wrench to increase the force applied.

- If the plug is difficult to access, use a breaker bar or two wrenches of different sizes. Place the closed end of one wrench on the bolt and the closed end of the other wrench over the open end of the first wrench to lock them together. This setup will provide more leverage and allow you to work in tight spaces.

Other Methods

- Use a bolt remover tool or a spiral screw extractor, which can grip the bolt more effectively.

- Vise grips or a pipe wrench can also be used to get a better grip on the bolt.

- Create a divot in the bolt using a centre punch and a hammer. Turn the punch 45 degrees and tap it again. This will loosen the plug, making it easier to remove.

- Cut a slit in the bolt and use a flat-head screwdriver to turn it counter-clockwise.

- Drill out the bolt, but be cautious as this can create sparks.

Remember to replace the drain plug after successfully removing the stripped one. It is also important to torque the new drain plug to the correct specification to prevent overtightening and potential damage to the threads.

Martha Stewart Pans: Oven-Safe?

You may want to see also

A rounded-off head drain plug requires a specialty socket called a bolt extractor

An oil drain plug is a threaded bolt made from a soft metal like aluminium, tightened to the bottom or side of the engine oil pan. The threads on the plug or pan can get stripped, or the gasket can break, causing oil to leak. This can eventually cause engine problems, allowing contaminants to enter the underside of the engine oil pan and create messy garage floors.

A rounded-off head drain plug can be caused by the use of an improperly sized wrench or socket during prior removal/installation. This can also occur when a standard socket is used in a metric application or vice versa. Once a drain plug's head begins to round off, further rounding over the course of successive oil changes is likely.

Alternatively, a pipe wrench can be used to grip the rounded-off head of the drain plug. However, this requires hitting the handle of the pipe wrench hard to crack the bolt loose.

Batter Volume: Loaf Pan vs Jumbo Muffin Tray

You may want to see also

Frequently asked questions

This could be due to a number of reasons. One of the most common causes is the use of soft metals like aluminum for the drain plug, which can strip easily if overtightened. Another reason could be cross-threading, which occurs when the plug is not installed straight and is forced the rest of the way.

There are several methods to remove a seized oil drain plug. One common method is to use a wrench or socket wrench to rotate the plug counterclockwise while also applying outward force on the plug. If the plug is difficult to access, you may need to use an extension to reach and unscrew it.

A seized oil drain plug can lead to oil leaks, which can cause engine damage and even engine failure if not addressed promptly. The oil may also hit dangerously low levels or empty completely, resulting in increased friction, heat buildup, and potential seizure of moving engine components.