The pan on a VW Beetle is the chassis and can be removed and replaced. The process of removing a VW pan involves first removing the pedal assembly, which requires unhooking the throttle cable and bolts, and disconnecting the clutch cable. There are also a few techniques to remove stubborn rusted screws, such as using penetrating lubricant or a bolt extractor.

What You'll Learn

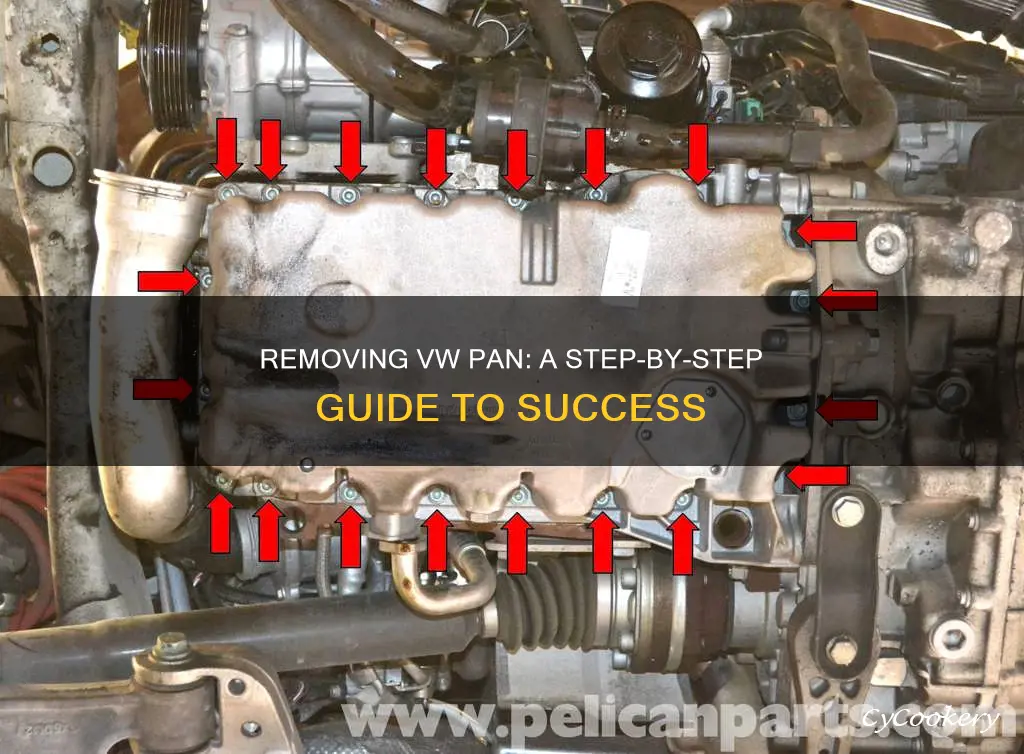

Removing transmission pan on a VW Passat

Removing the transmission pan on a VW Passat can be a challenging task, but with the right tools and procedure, it can be accomplished successfully. Here is a step-by-step guide to help you through the process:

Step 1: Prepare the Vehicle

Before beginning the removal process, make sure you have the necessary tools, such as a jack, jack stands, and a transmission jack. Place the vehicle on a level surface, engage the parking brake, and chock the wheels for safety.

Step 2: Drain the Transmission Fluid

Position a suitable drain pan under the transmission pan to collect the fluid. Locate and remove the transmission fluid drain plug, allowing the fluid to drain completely. Replace the drain plug securely.

Step 3: Remove the Undercarriage Components

This step involves removing components that may interfere with accessing the transmission pan. This includes the exhaust system, axles, fluid lines, wires, and transmission mounts. It is important to refer to a repair manual specific to your VW Passat model for detailed instructions on removing these components.

Step 4: Disconnect Electrical Connections

Locate and disconnect the electrical connectors associated with the transmission. This includes the electrical connector at the front, above the pan, the speed sensor, and any other relevant connections.

Step 5: Remove the Shift Cable

The shift cable is typically located on the driver's side. Remove the bolt holding the shift cable to the mount, and carefully detach the cable from the ball joint or similar mechanism.

Step 6: Remove the Transmission Mounts

Using the appropriate tools, remove the transmission mounts that secure the transmission to the vehicle's subframe or chassis. This will involve unbolting the mount brackets, which are typically attached with multiple bolts.

Step 7: Remove the Transmission Pan

With the transmission mounts removed, you can now access and remove the bolts securing the transmission pan to the transmission. Depending on the model, you may need to raise or lower the engine slightly to access all the bolts. Once all the bolts are removed, carefully separate the transmission pan from the transmission.

Step 8: Clean and Inspect the Transmission Pan

Before reinstallation, it is important to clean the transmission pan thoroughly and inspect it for any signs of damage or wear. If the pan is damaged or excessively worn, it may need to be replaced.

Step 9: Reinstallation

When reinstalling the transmission pan, ensure that a new gasket or sealant is used to create a secure seal. Follow the steps in reverse, torque the bolts to the manufacturer's specifications, refill the transmission fluid, and address any other components that were removed or disconnected during the process.

It is important to note that this guide provides a general overview of the process, and specific steps may vary depending on your VW Passat model and transmission type. Always refer to a reliable repair manual or seek the assistance of a qualified mechanic if you are unsure about any part of the procedure.

Bullet Lubing: Pan Lubing Basics

You may want to see also

Removing rusted screws

Method 1: Shock, Break, and Lube

First, put on some heavy leather gloves and safety goggles to protect your hands and eyes from any flying debris or rusted metal fragments. Then, grab a ball peen hammer and strike the screw head firmly several times. This action will break the rust seal and create channels for the rust penetrant to seep in and lubricate the screw.

Next, apply a rust penetrant, such as WD-40 Specialist Rust Release, PB Blaster, or Liquid Wrench, around the screw head. Allow it to soak for a few minutes. Then, strike the screw head with the hammer again and tap the metal surface around the screw to drive the penetrant deeper into the screw threads.

After this, attempt to remove the screw with a screwdriver. If the screwdriver slips out or starts stripping the screw head, stop! At this point, you can add an automotive valve grinding compound, such as Permatex, to the screw head to improve grip. Alternatively, create a gripping paste by mixing powdered kitchen or bathroom cleanser with a few drops of water, and apply it to the screw head. Then, try removing the screw again with the screwdriver.

Method 2: Apply Heat

If the screw still won't budge, you can try applying heat. However, this method should be used as a last resort, as it can ignite flammable rust penetrants and damage internal plastic parts. Make sure to remove any traces of rust penetrant or solvent using a water-based grease-cutting household cleaner and properly dispose of the oily rags.

Don your heavy leather gloves and keep a fire extinguisher nearby as a safety precaution. Apply heat to the screw head using a butane lighter or a small torch with low to moderate heat. Heat the screw until you see steam or smoke, but be careful not to let it turn cherry red. Immediately cool the screw with a stream of water or a wet rag. The expansion from heat, followed by rapid cooling, will help break the rust bond.

After several heat and quench cycles, attempt to remove the screw with the appropriate screwdriver. If the screw starts to turn and then binds, apply rust penetrant to the screw head and turn it back and forth to spread the penetrant down the threads.

Method 3: Cut It Out

If all else fails, you may need to cut the screw out. If the screw head is accessible, you can use a clamp to snap it off with force. Alternatively, use a screw extractor set to remove the stuck screw. Start by slowly driving a cobalt drill bit into the screw head. Then, replace the bit with a screw extractor bit, switch your drill to reverse, and begin drilling into the small hole you created.

Additional Tips:

- If you don't have rust penetrant, you can create your own by mixing equal parts acetone or nail polish remover with transmission fluid or sewing machine oil.

- Always start with gentle methods to avoid damaging or breaking off the screw heads. Move on to more aggressive methods if the gentle approaches don't work.

- When using a screwdriver, be careful not to strip the screw head. If you feel like you can't keep the screwdriver in the screw head, stop turning to avoid making the removal more difficult.

Anodized Pans: Dishwasher-Safe?

You may want to see also

Pulling the body off a VW Beetle

The VW Beetle is a beloved car model worldwide, known for its cool, cute, economical, and fun design. It is also super simple and easy to work on. Pulling the body off a VW Beetle involves removing the necessary parts, carefully jacking up the car, and unthreading bolts to separate the body from the pan or chassis. Here is a step-by-step guide to help you through the process:

Step 1: Remove Necessary Parts

Before you begin, it is important to remove certain parts from the Beetle. This includes the motor, seats, and gearshift. This step will give you better access to the body and chassis.

Step 2: Prepare Jacks and Dolly

For this step, you will need a 7-ton jack, an ATV jack, a body dolly, and some 2x4 pieces of wood. Place the 7-ton jack under the front nose of the car and the ATV jack under the rear apron. Use the 2x4 pieces of wood to distribute the load and protect the body. Place the body dolly nearby, ready to receive the body.

Step 3: Jack Up the Car

Slowly jack up the front and rear of the car in small increments, ensuring you maintain balance on both jacks. Check the balance frequently as you raise the car. Once you have enough height, carefully roll the jacks sideways towards the body dolly, moving very slowly to keep the body stable.

Step 4: Lower onto Dolly

Once you have cleared the chassis, carefully lower the body onto the dolly in small increments, moving from front to back to maintain balance. Ensure you have a stable base on the jacks to support the body.

Step 5: Unthread Bolts

Now that the body is separated from the chassis, you can begin unthreading the bolts that connect the two. This includes bolts at the back end of the spare tire well, inside the front firewall, at the rear quarter cross members, at the rear fender well, underneath the car at the front of the floor pans, along the sides of each floor pan, and at the very front of the pan. Use the appropriate tools, such as a flat-blade screwdriver, impact driver, ratchets, sockets, and a cheater bar, as needed.

Step 6: Lift Body Off Chassis

Once all the bolts are removed, carefully lift the body off the chassis. You may need an assistant to help with this step. And that's it! You have successfully pulled the body off your VW Beetle. Remember to work slowly and carefully throughout the process to ensure the safety of yourself and your car.

Aluminum Foil: Safe Baking Pan Cover?

You may want to see also

Removing the pedal assembly

Firstly, loosen the clutch cable adjustment nut with a wrench, and use pliers or vice grips to prevent the cable from twisting while you remove the nut. Next, remove the two bolts holding the pedal assembly in place. Pull the accelerator cable off the linkage end, and then remove the push rod pin by prying up the brake pedal push rod clip with a flathead screwdriver. After this, remove the push rod from the master cylinder and brake pedal, and then pull the pedal assembly forward slightly to detach the clutch cable from the pedal hook. Finally, remove the pedal assembly from the car.

There are some additional steps to be aware of. Firstly, there is a stop plate for the brake pedal that needs to be loosened before removing the assembly. This is a 13mm bolt in front of the pedals. Secondly, the clutch cable should be hooked over the clutch "hook". Thirdly, there is a spring that holds the pin for the brakes, which can be unhooked by pushing it forward. Finally, when reinstalling the pedals, some people put tape or a rubber band around the clutch cable to stop it from falling off during the process.

Colourpop Pans: What's the Size?

You may want to see also

Removing a VW Bug body from the floor pan

The VW Beetle is a beloved car for enthusiasts around the world. The car is cool, cute, economical, fun, and super simple and easy to work on.

The pan on a VW Beetle is the "chassis" and when bolted together, they make a unibody car. However, they can come apart and a VW pan can roll around on its own.

If you want to remove a VW Bug body from the floor pan, you will need to follow these steps:

Firstly, gather your tools. You will need a wrench, a socket set, and possibly some pliers or vice grips.

Next, you will need to locate the bolts that hold the body and pan together. These are usually found around the perimeter of the car, where the body and pan meet. There may be as few as 27 bolts, but this will vary depending on the model of your VW Bug.

Once you have located the bolts, use your wrench to remove them. Be careful not to round off the heads of the bolts as you apply force. If the bolts are rusted, you may need to apply some penetrating lubricant to help loosen them. Try to avoid drilling or cutting the bolts, as this can damage the threads and make it difficult to install new bolts.

If you are unable to remove the bolts with a wrench, you may need to use a bolt extractor or a similar tool. These tools are designed to grip the head of the bolt and allow you to apply more force without slipping.

Once all the bolts are removed, the body of the VW Bug should be separated from the floor pan. Be careful when lifting and moving the body, as it may be heavy and unwieldy.

With the body removed, you can now access the interior of the car and make any necessary repairs or modifications. This process can also be done in reverse to install a new body onto an existing floor pan.

Caraway Cookware: Oven-Safe?

You may want to see also