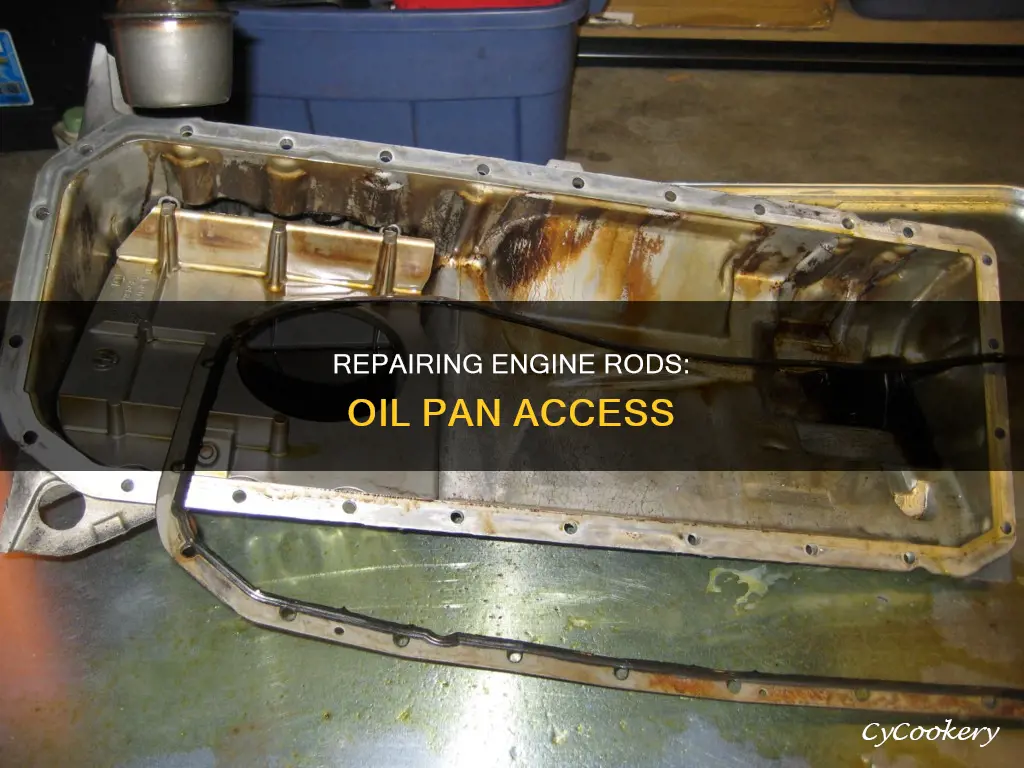

If you're hearing a knocking noise from your car engine, it could be time to replace the rod bearings. The rod bearings are located between the connecting rods and the crankshaft in your engine and can wear down over time due to friction and heat. While it is possible to replace rod bearings without removing the engine, it is a more challenging task. The process involves removing the oil pan, draining the oil, and carefully removing and replacing the bearings. However, it is important to note that you cannot replace rod bearings through the oil pan, as the oil pan needs to be removed for access.

| Characteristics | Values |

|---|---|

| Difficulty | Relatively easy to do at home with basic tools, but requires patience |

| Tools Required | Basic tools, including a press or hammer |

| Cost | $600 to $1,200 for connecting rod bearings; $2,000 to $3,000 per side for rod bearings |

| Time | A few hours |

| Engine Removal | Not necessary |

| Oil Pan Removal | Required |

| Cause | Oil starvation, overheating, excessive wear and tear, or impact |

What You'll Learn

Removing the oil pan and draining the oil

Before you begin the process of repairing a rod through the oil pan, it is important to remove the oil pan and drain the oil. This will give you better access to the rods and bearings. Here is a step-by-step guide on how to do this:

- Drain the old oil from the engine's oil pan. You can do this by removing the plug at the bottom centre of the pan and allowing the fluid to run into a catch basin or drip tray. Make sure you dispose of the used oil properly, as it needs to be recycled according to environmental regulations.

- Remove the oil pan. To do this, you will need to loosen and detach all the bolts holding the oil pan in place. Use an adjustable wrench or socket wrench for this task. If the bolts are difficult to access, you may need an extension bar. Loosen the bolts in a circular pattern to ensure they are completely undone.

- In some cases, you may also need to remove other parts and brackets to access the oil pan bolts. A service manual can be helpful to identify all the bolt locations.

- Once all the bolts are removed, gently lift off the old oil pan. You may need to tap it lightly with a mallet to break the seal. Be careful not to bend or crack the oil pan during this process.

- After removing the oil pan, check it for metal shavings, sludge, or other debris that could indicate potential problems. Clean the oil pan thoroughly before reinstalling it.

- If you are installing a new oil pan, make sure you have the correct size and check the clearance between the oil pan and nearby objects such as suspension parts, transmission components, or fuel lines.

- Follow the manufacturer's instructions for installing the new oil pan, including replacing the gasket and tightening the bolts to the specified torque settings.

Remember to work carefully and patiently throughout this process to ensure a successful repair.

Greasing the Pan: Ice Ring Essential?

You may want to see also

Removing the connecting rod and piston

Firstly, it is important to note that removing the piston through the oil pan is a challenging task and may not always be successful. In some cases, it may be necessary to remove the head and take out the piston in the conventional way. However, if you wish to attempt removal through the oil pan, proceed with caution. Ensure that you have already removed the oil pan and located the connecting rods and bearings.

The next step is to lower the piston. You will need to lower it enough to slide out the wrist pin, but be careful to leave it high enough so that the rings remain inside the bore. This is a crucial step to ensure the piston can be safely removed without causing further damage.

Once the piston is lowered, carefully measure the distance from the mains to the bottom of the cylinder. This will help you determine if there is sufficient clearance to slide out the piston. In some cases, the piston may be too large to fit through the bottom, and alternative methods may need to be considered.

If there is enough clearance, the next step is to remove the rings from the block. This is important to ensure that there is enough room to reinstall the piston from the bottom. Failure to do so may result in difficulties during reinstallation.

Now, carefully slide out the piston through the oil pan opening. This may require some maneuvering, and it is important to work slowly and deliberately to avoid causing any accidental damage.

Once the piston is removed, carefully inspect the cylinder and remove any debris that may have accumulated. This is important to ensure that the engine remains clean and free of any foreign material.

Finally, with the piston and connecting rod removed, you can proceed to install a new set or make the necessary repairs. It is important to follow the correct procedures and consult a professional if you are unsure about any steps.

Simple Guide to Removing Scale from Your Pan

You may want to see also

Cleaning the engine and replacing the oil pan gasket

To clean the engine and replace the oil pan gasket, you'll first need to remove the oil pan. Before doing so, it's important to lift the front end of your car onto a pair of jack stands or ramps, block the rear wheels, and set the emergency brakes. Place a large drain pan under the engine oil pan and unscrew the drain plug from the bottom of the pan to allow the oil to drain completely.

Once the oil has drained, locate any components that may prevent you from dropping the pan or reaching the pan mounting bolts, such as cross members, exhaust pipe components, or support brackets. After gaining full access to the oil pan, loosen all the bolts located around the pan flange. In some cases, you may need to use a swivel socket, a long ratchet extension, and a ratchet tool to reach some bolts. Finish removing the bolts and pull the pan off the bottom of the engine block. If the pan seems stuck, tap it lightly with a rubber mallet to break the oil pan seal.

With the oil pan removed, it's time to clean the engine and prepare for the new gasket. Check the bottom surface of the pan for metal shavings, which may indicate excessive wear of engine components. Thoroughly clean the engine and oil pan mating surfaces, scraping off any old gasket material or silicone. Use a solvent to clean the mating surfaces, and if necessary, wash the pan using a cold soak cleaner. For stubborn grease and gum, use a carburetor cleaner or engine degreaser and a wire brush. Check the pan for any damage, such as cracks, and inspect the pan flange for bends.

Now it's time to install the new gasket. Refer to your vehicle service manual and the instructions that come with the new gasket to determine the type of seal and any necessary adhesives or sealants. Carefully position the pan under the engine block, ensuring that the sealer or gasket doesn't smear or move. Start the pan bolts by hand, tightening them lightly in a crisscross pattern. Some manufacturers recommend applying a bit of sealer to the bolts' threads before installation, so check your service manual for specific instructions. Finally, tighten the bolts with a torque wrench to the specified torque, following the same crisscross pattern.

With the new gasket installed, replace all the components that were removed to gain access to the oil pan. Lower the engine and tighten the motor mounts if necessary. Refill the engine with the proper amount and recommended type of engine oil for your vehicle.

Check for oil leaks after pouring in the oil and during the following days to ensure a successful repair.

Hang Pizza Pans with Ease

You may want to see also

Reattaching the oil pan and refilling the crankcase with oil

Once you have completed the necessary repairs, you can reattach the oil pan and refill the crankcase with oil. This process will vary depending on your vehicle's specific make and model, but there are some general steps you can follow.

First, you will need to clean the oil pan and lower crankcase. This is important to remove any dirt, debris, or old gasket material that could prevent a proper seal. Use a detergent that breaks down oil, such as Simple Green, and soft, non-metal tools like plastic scrapers and shop rags to avoid damaging the soft aluminum engine parts. Be sure to pay extra attention to the surfaces where the gaskets will sit.

Next, you will need to install a new oil pan gasket. This is crucial to ensure a proper seal and prevent oil leaks. Follow the manufacturer's instructions for your specific gasket, and be sure to torque the gasket to the specified value.

Once the new gasket is in place, you can reinstall the oil pan. Again, follow the manufacturer's instructions for your specific vehicle and torque the oil pan bolts to the specified value.

Finally, you can refill the crankcase with fresh oil. Be sure to use the correct type and amount of oil for your vehicle, as specified in your owner's manual. Start the engine and check for any leaks. If no leaks are evident, take your vehicle for a short drive and check again. If the oil pan and drain plug remain dry, your repair was likely successful.

It is important to note that repairing an engine through the oil pan can be a complex process, and it may be necessary to consult a qualified mechanic or repair manual for specific instructions.

Olive Branch Pan: A Guide to Getting Yours

You may want to see also

Checking for leaks

Once you have repaired the engine rod through the oil pan, it is important to check for leaks. Engine oil leaks are one of the most common causes of engine damage, leading to rapid deterioration and costly repairs. They can also be a safety hazard, potentially causing a loss of control while driving.

To check for leaks, first, prepare the vehicle. Park on a level surface, engage the parking brake, and chock the rear wheels. Then, use a jack to raise and support the car, and place a container under the oil pan. Remove the drain plug to drain the oil, and then reinstall the plug to prevent dripping.

Next, remove any necessary components to access the oil pan, and then unbolt and remove the oil pan. Clean the mounting location on the engine with solvent, ensuring it is completely clean for the new gasket to form a good seal.

Now you can install the new gasket and the oil pan. Place the gasket on top of the pan and insert a couple of bolts to hold it in place. Then, thread the remaining bolts in by hand and tighten them to the manufacturer's specifications.

Once the pan is in place, carefully remove the jack stands and lower the vehicle. Refill the engine with the correct amount of fresh oil and reconnect the negative battery cable.

Finally, start the engine and check for leaks. Top off the oil level if needed, and then run the car for a few minutes. Move the vehicle a short distance and check for any oil leaks on the ground. If you still see a puddle, you will need to recheck and tighten the bolts.

Cast Iron Pan Handles: Hot or Not?

You may want to see also

Frequently asked questions

If your car is making a knocking noise, it could be time to replace the rod bearings. The rod bearings sit between the connecting rods and the crankshaft in your engine. Over time, they can wear down from friction and heat.

The first step is to remove the oil pan from your engine so you have access to the rod bearings. Once the oil pan is off, you will need to remove the old bearings and install new ones.

Replacing rod bearings is a relatively easy job that you can do at home with some basic tools. However, if you don't feel comfortable doing it yourself, there's no shame in taking your car to a mechanic.