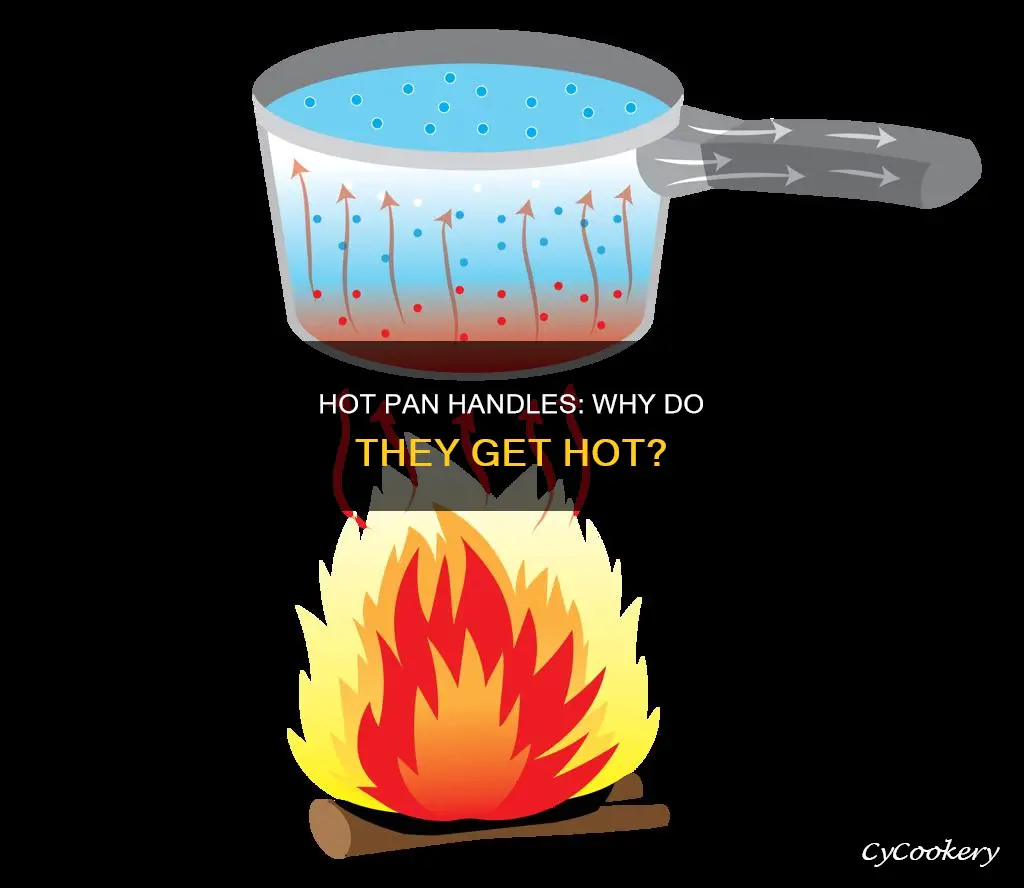

Pans with metal handles can get hot because different materials heat up at different rates. The texture of the grip can also have an impact; a smooth handle will transfer more heat to your hand, while some textures can act as tiny cooling fins, reducing the contact area for conduction and increasing the surface area for cooling. The shape and orientation of the handle also matter when it comes to convective heat loss. Additionally, the type of metal used in the handle plays a role, with aluminium and copper being particularly good heat conductors.

| Characteristics | Values |

|---|---|

| Handle material | Metal, silicone, plastic, wood |

| Handle texture | Smooth, other textures |

| Handle thickness | Thick, thin |

| Handle shape | Bent sheet metal, solid |

| Handle connection to pan | Thin, long, bolted on |

| Pan material | Metal, cast iron |

| Pan type | Frying pan, skillet |

| Pan size | Small, large |

| Heat source | Stove, oven |

| Heat level | Low, medium, high |

| Burner size | Small, large |

What You'll Learn

- Handle texture: a smooth handle transfers more heat than textured handles, which act as cooling fins

- Handle material: metal handles conduct heat better than plastic or wood

- Handle shape: bent sheet metal handles stay cooler than solid handles

- Handle connection: a thin, long connection to the pan reduces heat transfer

- Pan material: cast iron pans conduct heat to the handle

Handle texture: a smooth handle transfers more heat than textured handles, which act as cooling fins

The texture of a pan handle can significantly impact how hot it gets. A smooth handle will transfer more heat to your hand, whereas a textured handle will act as a cooling fin, providing more surface area for cooling and reducing the contact area for conduction. This means that a textured handle will stay cooler than a smooth one, even if made of the same material.

The reason for this lies in the physics of heat transfer. When a textured surface is introduced, it alters the way heat is dissipated. The surface area of the handle increases due to the texture, improving its ability to get rid of heat. Additionally, the texture creates a larger area for convection currents to form, aiding in the transfer of heat away from the handle.

The degree of roughness or texture on a surface can be measured by comparing the surface area that can come into contact with a liquid to that of a completely smooth surface. A higher degree of roughness leads to a greater heat-dissipation capability, as more surface area is available for cooling. This principle has been demonstrated by researchers at MIT, who found that a simple roughening of a surface improved heat transfer as much as more complex previous techniques.

Therefore, when choosing a pan, consider the texture of the handle in addition to the material. A textured handle will provide a more comfortable and safer grip by reducing the amount of heat transferred to your hand. This is especially important for stovetop use, where handles can quickly become too hot to touch. By choosing a pan with a textured handle, you can improve your cooking experience and avoid the need for oven mitts or hot pads.

Crispy Pan Pizza: DiGiorno's Costly Delight

You may want to see also

Handle material: metal handles conduct heat better than plastic or wood

The material used for a pan's handle plays a significant role in how hot it gets during cooking. Metal handles, for instance, are excellent heat conductors, which means they can quickly become too hot to handle without protective mitts. This is because metal is a highly conductive material that readily transfers heat from the pan to your hand.

On the other hand, handles made of materials like plastic or wood tend to stay cooler for longer. This is because these materials are poor heat conductors, preventing the handle from heating up as quickly as metal. Plastic and wooden handles have higher heat resistance and do not conduct heat as efficiently as metal, allowing them to stay cooler for a longer period of time.

The design of the handle also influences how hot it gets. Handles with a thin connection to the pan and a larger surface area will cool down faster due to increased contact with the air. Additionally, the length of the handle matters; longer handles tend to stay cooler than shorter ones.

The type of metal used in the handle can also make a difference. For example, stainless steel is generally a poor heat conductor, making it a good choice for handles. Certain designs, like tubular handles or hollow-core cast stainless steel handles, further reduce heat conduction, keeping the handle cooler for longer.

In summary, the choice of handle material and design significantly impacts how hot a pan's handle gets during cooking. Metal handles, being excellent heat conductors, tend to get very hot, while plastic or wooden handles, with their poor heat conduction properties, stay cooler. Design features that increase surface area and length, as well as the use of specific types of metal, can also help keep handles from heating up too much.

Get Pizza Hut's New Pan Pizza: Here's How

You may want to see also

Handle shape: bent sheet metal handles stay cooler than solid handles

Bent sheet metal handles tend to remain cooler than solid handles. This is because the rate of heat transfer from the pan to the handle is influenced by the shape and orientation of the handle. Bent sheet metal handles have a larger surface area, which allows for more effective heat dissipation through convection. Additionally, the thin connection between the handle and the body of the pot reduces the amount of heat transferred from the pan to the handle.

The design of the handle plays a crucial role in managing the heat transfer. By separating the attached section of the handle into smaller sections, the amount of material available to conduct heat is reduced. This design choice also increases the surface area for heat radiation. Furthermore, the main part of the handle is often hollow, reducing weight and improving heat dissipation.

The choice of metal also impacts the handle's temperature. Different metals have varying thermal conductivities, with aluminium and copper being particularly efficient heat conductors. Stainless steel, on the other hand, conducts heat at a slower rate, resulting in a cooler handle.

The orientation of the handle is another factor. Handles positioned to the side of the pan are less likely to be heated directly by the stove's heat source. Additionally, the length of the handle can influence the temperature gradient, with longer handles exhibiting a smaller temperature difference along their length.

Overall, the combination of shape, orientation, and material choice in bent sheet metal handles contributes to their ability to stay cooler than solid handles.

Roaster Pan Makeover: Dressing Up for the Feast

You may want to see also

Handle connection: a thin, long connection to the pan reduces heat transfer

The design of a pan's handle plays a crucial role in determining how hot it gets during cooking. A thin, long connection between the handle and the pan is a key feature in reducing heat transfer to the handle, thereby keeping it cooler for longer. This design choice takes advantage of several physical principles to minimise heat conduction and maximise heat dissipation, making it safer and more comfortable to handle the pan.

Firstly, the thin connection between the handle and the pan acts as a bottleneck for heat transfer. As heat moves from the pan to the handle, the thin connection slows down the rate at which heat can flow. This is because the amount of heat transferred is proportional to the cross-sectional area of the connection. By keeping the connection thin, the amount of heat flowing into the handle is reduced.

Secondly, the long connection between the handle and the pan provides more time for heat to dissipate into the surrounding air before reaching the handle. This is similar to how a longer pipe allows more time for fluid to flow out or leak out. The longer the distance heat has to travel through the handle, the more opportunity there is for the heat to escape into the surrounding environment.

Additionally, the large surface area of the handle, compared to the thin connection, further promotes heat loss to the surrounding air. As heat moves up the handle, the increased surface area allows more heat to be released, preventing it from reaching the top of the handle. This is similar to how a person with a large surface area, such as by wearing a wide coat, can lose body heat more effectively.

The effectiveness of this design is influenced by the material of the handle. Metals, such as aluminium and copper, are excellent heat conductors, so they quickly transfer heat up the handle. On the other hand, materials like wood and plastic are poor heat conductors, slowing down the rate at which heat moves up the handle. Therefore, a long, thin metal handle may still require an oven mitt to handle comfortably, whereas a long, thin plastic or wooden handle may not.

Furthermore, the shape and orientation of the handle also impact heat transfer. Bent sheet metal handles tend to stay cooler than straight solid handles due to their increased surface area and altered airflow. A handle that is tilted upwards will also stay cooler than one that is horizontal, as heat rises and a tilted handle provides more surface area for heat to escape.

In summary, a thin, long connection between the handle and the pan is an effective design choice for reducing heat transfer to the handle. This design slows down the rate of heat conduction, provides more time and surface area for heat dissipation, and can be further optimised by considering handle material, shape, and orientation. These factors collectively contribute to a safer and more comfortable cooking experience by minimising the risk of burns from hot handles.

The Lodge Cast Iron Legacy: American-Made and Going Strong

You may want to see also

Pan material: cast iron pans conduct heat to the handle

Metal is a good conductor of heat, and cast iron pans are made entirely of metal. Therefore, the handles of cast iron pans will get hot.

Cast iron is one of the only types of cookware that can be used over a campfire, and it can withstand high temperatures of up to 650˚ F. This makes cast iron a great option for almost any heat source, including electric, induction, and gas cooktops, as well as gas grills, charcoal grills, and campfires.

The texture of the handle can also affect how hot it gets. A smooth handle will transfer more heat to your hand, while a textured handle can act as tiny cooling fins, reducing the contact area for conduction and increasing the surface area for cooling.

Some cast iron pans have detachable handle covers made of materials like leather or silicone, which can help to protect your hands from the heat. Scandinavian and Japanese brands of cast iron pans commonly feature wooden handles, which are better at resisting heat conduction.

Mold Exposure: Can It Cause Chest Pains?

You may want to see also

Frequently asked questions

The handles of a pan can get hot due to the heat transfer from the pan's body. The rate at which this happens depends on the material and shape of the handle. Metal handles, especially aluminium and copper, tend to conduct heat better and get hotter faster. Plastic and wooden handles are slower to conduct heat and therefore stay cooler for longer.

The shape and orientation of the handle, as well as the length and thickness, play a role in how hot a handle gets. Longer stick handles tend to stay cooler than shorter side handles. Thin, bent sheet metal handles also stay cooler compared to solid handles. Additionally, the type of burner and heat setting can impact the handle's temperature.

To prevent the handles from getting too hot, use a burner that closely matches the size of your pan. Centre the pan on the burner and use low to medium heat. You can also use pot holders, handle sleeves, or opt for pans with hollow-core stainless steel handles, which stay cooler for longer.