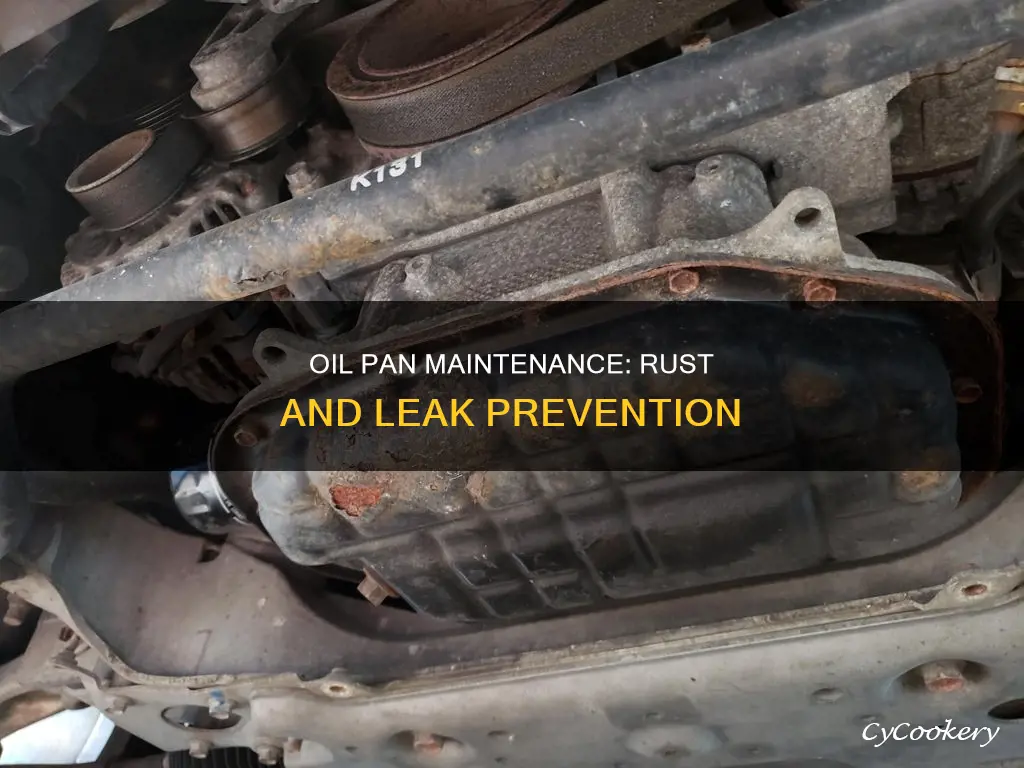

Oil pans can rust and leak oil, and this is a common issue that car owners face. The rusting usually starts from the outside, with a small stone chip in the paint on the oil pan exposing bare metal, which then oxidises and allows rust to eat its way in. This can eventually cause oil leaks. While there are DIY solutions to this problem, such as cleaning the pan and applying a rust-resistant coating, it is often more cost-effective to simply replace the oil pan, especially if the rust is severe.

| Characteristics | Values |

|---|---|

| Can oil pans rust? | Yes |

| What causes the rust? | Exposure to grit, scrapes, road salt, and debris |

| How does rust lead to leaks? | Rust eats its way in from the outside and eventually reaches the oil |

| Can a rusty oil pan be repaired? | It is not cost-effective to repair a rusty oil pan; replacement is the best choice |

| How can you prevent rust? | Clean and spray the oil pan with a rust-resistant paint or black undercoating |

What You'll Learn

Oil pans can be made of steel or aluminium

Oil pans are typically made of steel or aluminium. Steel pans are generally used for off-road vehicles as they can take a few hits before they dent and leak. They are also much cheaper to replace than aluminium pans. However, cast aluminium pans are more resistant to corrosion and therefore last longer.

Aluminium pans are also being used in some newer car models. These pans are made of thermoplastic composites, which are lighter and less costly than their metal counterparts. They are also more resistant to corrosion and denting, and reduce assembly costs. However, metal pans are still more commonly used due to concerns about the high costs of potential warranty issues if composite pans do not work.

Oil pans made of steel are produced with a stamp-forming process and are physically lighter than aluminium pans because they are made with a thin steel sheet. In contrast, aluminium pans are thicker and heavier. Steel pans have higher ductility but lower hardness compared to aluminium pans, which have high hardness and low ductility.

Taming the Smoke Beast: Mastering Smoke-Free Cast Iron Cooking

You may want to see also

Steel pans are cheaper but more prone to rusting

Oil pans can rust and leak oil, and steel pans are more prone to rusting than cast aluminium units. Steel pans are, however, generally much cheaper to replace.

Steel oil pans are often the preferred choice for off-road vehicles as they can take a few hits and get dented before leaking. They are also better at withstanding grit and scrapes from the road. However, once the paint layer is broken or chipped, the metal becomes exposed to the elements and rust can start to form. The quality of the steel and paint job, as well as the amount of road salt and debris the pan is exposed to, will affect how long it lasts. On average, oil pans need to be replaced around the eight- to nine-year mark.

There are ways to prolong the life of a steel oil pan. After about five years, a little cleaning and a spray with a rust-resistant paint or black undercoating can help. For vehicles with higher ground clearance, this can be done at home. For vehicles with less room under the chassis, it may be necessary to jack up the vehicle or enlist the help of a mechanic.

If you notice rust on your oil pan, it is important to address it as soon as possible. Chipping off loose rust and applying a rust converter or primer can help to slow down the rusting process. However, paint does not stick well to rust, so surface preparation is key. If the rust is extensive, it may be best to simply replace the oil pan, which is usually a relatively easy and inexpensive repair.

Pan Pizza: Pizza Hut's Best Toppings

You may want to see also

Aluminium pans are more resistant to corrosion

Aluminium is a popular choice for cookware due to its affordability, heat conductivity, and lightweight nature. However, concerns have been raised about the potential health risks associated with aluminium leaching into food. Despite this, the connection between aluminium pans and Alzheimer's disease has been debunked, and the amount of aluminium that leaches into food during everyday cooking is relatively minor.

To further reduce the risk of corrosion in aluminium pans, it is recommended to avoid cooking salty or acidic foods, especially if they are liquid-rich. Regular cleaning with gentle detergents and avoiding the dishwasher can also help prevent corrosion. Additionally, opting for aluminium pans with a protective coating, such as anodised layers or powder coats, can provide an extra layer of protection against corrosion.

In summary, while aluminium pans are not completely corrosion-proof, they are more resistant to corrosion than steel pans due to their inherent properties and available protective coatings. With proper care and maintenance, aluminium pans can last for many years without posing any significant health risks.

Saucepan Sizes: What's the Standard?

You may want to see also

Rusting can be caused by road grit, paint chips, and exposure to the elements

Oil pans can rust and leak oil. The oil pan is a critical component of your car's engine, and it's important to keep it in good condition. Rusting can be caused by road grit, paint chips, and exposure to the elements. This is particularly true for steel oil pans, which are commonly used in off-road vehicles and light trucks. These pans are designed to take a beating and can withstand small impacts without leaking. However, the trade-off is that they are more susceptible to rusting.

As the oil pan is located close to the road, it is constantly exposed to road grit and debris. Over time, this can cause the paint layer on the pan to chip away, exposing the metal underneath to moisture and oxygen, initiating the rusting process. The formation of rust can also be influenced by various factors, including the quality of the steel and paint used, the amount of road salt in winter, and the drainage of the parking spot.

To prevent rust from forming on your oil pan, it is important to regularly clean and maintain it. This includes removing any debris or grit that may have accumulated and ensuring that the paint layer is intact. If the paint has started to chip, you can apply a rust-resistant paint or black undercoating to protect the metal and prevent rust from forming.

In some cases, the rust on an oil pan may be superficial and can be treated with a rust converter or a coat of alkyd paint designed for rusted metal. However, if the rust is more severe, it may be necessary to remove the pan and clean it thoroughly before repainting it. This process involves removing the oil pan, cleaning the rust from the bolts and the pan itself, and applying a new sealant before reinstalling the pan.

It is important to address any signs of rust on your oil pan promptly, as rust can weaken the structural integrity of the pan and increase the risk of leaks. By taking proactive measures and seeking professional assistance when needed, you can help ensure the longevity of your oil pan and maintain the overall health of your vehicle.

Steaming Green Beans: Pan Method

You may want to see also

Oil pans can be replaced or treated with a rust-resistant coating

Oil pans can be highly susceptible to rusting, especially those made of steel. This can lead to leaks, which can be dangerous if not addressed promptly. While cast aluminium pans are more resistant to corrosion, steel pans are preferred for off-road vehicles as they can withstand a few hits before leaking.

If you notice rust on your oil pan, it is important to take action to prevent further deterioration. One option is to replace the oil pan entirely, especially if the rust is severe or the pan is already leaking. This can be a complex process, depending on the make and model of your vehicle, and may require the expertise of a mechanic.

However, if the rust is superficial, you may be able to treat and prevent further corrosion by applying a rust-resistant coating. This process typically involves cleaning and degreasing the oil pan, neutralising and etching the metal, and then applying a rust-preventive coating. It is recommended to use a product specifically designed for this purpose, such as POR-15 Rust Preventive Undercoating, which offers impact resistance and rust protection.

To extend the life of your oil pan, it is important to maintain it properly. This includes regular oil changes and ensuring the area is well-drained and free from debris. Additionally, you can apply a rust-resistant paint or black undercoating to steel oil pans after about five years of use. For vehicles with higher ground clearance, this can be a simple DIY task. Alternatively, you can jack up the vehicle safely or enlist the help of a mechanic.

By taking proactive measures and staying vigilant, you can help prevent rust from becoming a major issue and keep your vehicle in good condition for years to come.

Mirro Pans: Oven-Safe?

You may want to see also

Frequently asked questions

Yes, oil pans can rust and leak oil. The rust usually starts from the outside and works its way in, with the metal oxidizing and rust eating through the oil pan.

For steel oil pans, rust starts when the paint layer is broken or chipped, exposing the metal to the elements. The amount of road salt in winter, how much debris the pan is exposed to, and how well-drained its parking spot is, can also contribute to rust.

You can prolong the life of a steel oil pan with some DIY care. After about five years on the road, clean the pan and spray it with a rust-resistant paint or black undercoating.

If the rust is only superficial, you can try to brush off the thickest parts of the rust, degrease the pan, and apply a coating of enamel or paint that seals and prevents rust. However, if the rust is severe, it is usually more cost-effective to simply replace the oil pan.