RTV (Room Temperature Vulcanizing) silicone is used to seal valve covers, oil pans, timing covers, transmission pans, and other parts. It is applied to both surfaces being joined, and then the parts are pressed together and left to cure. Gaskets are used for the same purpose but are made of cork, rubber, or paper. RTV is favoured by some because it is quick and easy to use, fills gaps, and does not need to be replaced like a gasket. However, it can be messy and time-consuming to clean off. Gaskets are preferred by others because they are easy to replace and do not run the risk of falling off in chunks and clogging passages.

| Characteristics | Values |

|---|---|

| RTV Use | RTV is applied to the corner(s) or stepped areas on the engine so as not to smear the RTV during the installation of the component. |

| RTV Use Cases | Use RTV to seal corners and/or stepped joints where there are gaps. |

| RTV Application | Apply RTV only to the areas that need it. Remember that when the casting/gasket is torqued into place, the RTV will flow into the joint and gasket. |

| RTV Timing | The assembly should be installed within five minutes of the RTV application. RTV typically needs 24 hours for a full cure. |

| Gasket Application | Gaskets are to be installed clean and dry. |

What You'll Learn

RTV is only necessary at the corners or stepped areas of the oil pan gasket

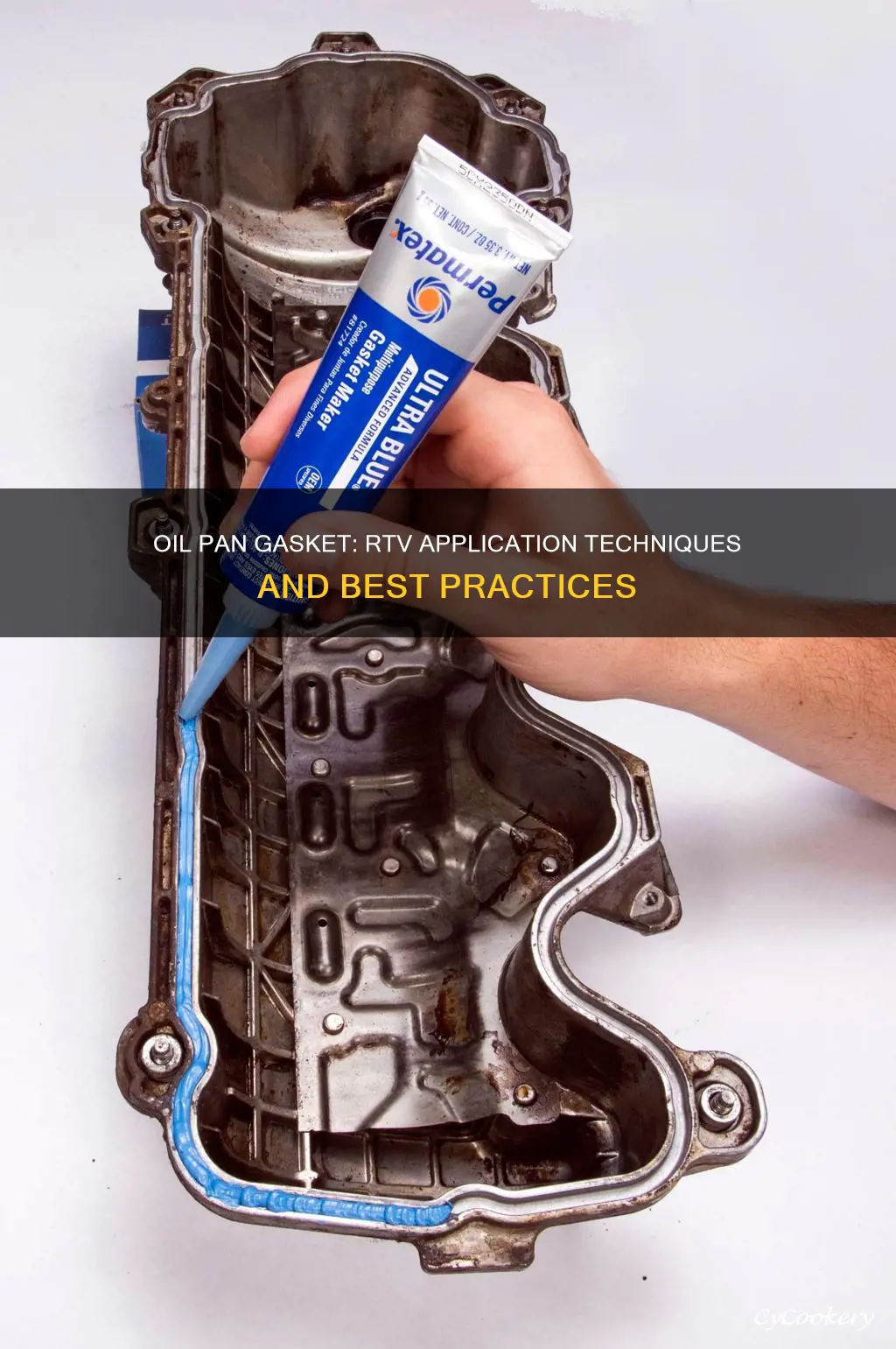

RTV should only be used on the corners of the gasket and/or stepped casting areas that have a gap. Using a small amount of RTV will fill in those areas to assure a leak-free assembly. RTV is typically applied to the corner(s) or stepped areas on the engine so as not to smear the RTV during the installation of the component.

For example, in the case of most Fel-Pro® oil pan gaskets, they are to be installed dry. When installing PermaDryPlus® and PermaDry® gaskets, they must be installed clean and dry. RTV is only necessary at the “corners” or where there may be a stepped area such as an RMB retainer to block joint.

It is important to note that RTV should not be used on the entire gasket. Applying RTV in the wrong areas can cause permanent damage to the gasket, such as over-compression and splitting. It may also cause the gasket to slide out of place. Rubber gaskets are designed to have a certain amount of compression applied to them, and the addition of RTV or a sealer puts more compression on the gasket than what it was designed for.

When using RTV, it is important to follow the manufacturer's recommendations and apply it only to the areas that need it. Remember that when the casting/gasket is torqued into place, the RTV will flow into the joint and gasket. Some manufacturers will recommend the amount of RTV to be applied, and it is important to remember that a little RTV goes a long way.

In summary, RTV is only necessary at the corners or stepped areas of the oil pan gasket to fill in gaps and assure a leak-free assembly. It should not be used on the entire gasket as it can cause damage and put too much compression on the gasket. Always follow the manufacturer's recommendations for proper use of RTV.

Salting a Cast Iron Pan: A Step-by-Step Guide to Seasoning Success

You may want to see also

RTV is not to be used on the entire gasket

RTV is typically applied to the corner(s) or stepped areas on the engine so as not to smear the RTV during the installation of the component.

Fel-Pro® oil pan gaskets, for example, are to be installed dry. When installing PermaDryPlus® and PermaDry® gaskets, they must be installed clean and dry. RTV is only necessary at the “corners” or where there may be a stepped area such as an RMB retainer to block joint.

RTV is not designed to be used as a supplement sealer on gaskets. Uncured RTV can act as a lubricant and cause the gasket to slip out of place. Rubber gaskets are designed to have a certain amount of compression applied to them. The addition of RTV or a sealer puts more compression on the gasket than what it was designed for.

Applying RTV in the wrong areas can cause permanent damage, such as over compression and splitting, to the gasket. It may also cause the gasket to slide out of place.

Therefore, RTV is not to be used on the entire gasket.

Calorie Count of Pan-Roasted Chicken Breasts

You may want to see also

The gasket should be installed clean and dry

When installing a new oil pan gasket, it is important to follow the manufacturer's instructions and recommendations for the specific type of gasket. In the case of most Fel-Pro® oil pan gaskets, they are to be installed dry, without any sealants or adhesives. However, there are exceptions, such as the PermaDryPlus® and PermaDry® gaskets, which must be installed clean and dry.

If you are using a gasket that requires a clean and dry installation, it is important to take the necessary steps to ensure that the gasket and the sealing surfaces are free from any dirt, grease, or oil. Here are some guidelines to follow:

- Clean the sealing surfaces: Before installing the gasket, make sure that the surfaces to which the gasket will be applied are thoroughly cleaned. Use a degreaser or a solvent to remove any grease, oil, or residue from the surfaces. This step is crucial because contaminants can interfere with the gasket's ability to form a tight seal.

- Dry the surfaces: After cleaning, ensure that the sealing surfaces are completely dry. Any remaining moisture or solvent residue can affect the gasket's adhesion and sealing performance.

- Handle the gasket with care: When working with the gasket, avoid touching the sealing surfaces with your fingers, as the natural oils from your skin can contaminate the surface. It is recommended to wear clean gloves when handling the gasket.

- Apply the gasket properly: Position the gasket carefully, ensuring that it is aligned correctly and securely in place. Follow any specific instructions provided by the manufacturer for the type of gasket you are using.

- Torque the bolts: Once the gasket is in place, refer to the vehicle's service manual or the gasket manufacturer's instructions for the recommended torque specifications and bolt tightening sequence. This will help ensure an even and secure seal.

- Re-torque the bolts: After the engine has gone through a few heat cycles, it is advisable to re-torque the bolts to further ensure a proper seal and prevent leaks.

By following these steps and adhering to the manufacturer's recommendations, you can ensure that your oil pan gasket is installed correctly, promoting a secure and long-lasting seal.

Best Pan for Caramelizing Onions: Non-Stick or Stainless Steel?

You may want to see also

RTV should be applied within five minutes of component installation

RTV, or room temperature vulcanizing, is a type of sealant that begins to cure as soon as it is exposed to air. It is water-repellent, adhesive, and holds its shape. It is commonly used as a building sealer, especially in bathrooms and kitchens, and in the automotive industry as an adhesive and sealant.

When using RTV to seal an oil pan gasket, it is important to follow the manufacturer's recommendations and use it only where necessary. Some moulded rubber gaskets may require RTV as a supplemental sealer in corners or stepped casting areas that have a gap. It is important to note that RTV should not be used on the entire gasket, only on specific areas that require it.

When applying RTV, it is recommended to install the assembly within five minutes of the application. This is because, once the engine component is installed and torqued up, the RTV needs time to set up and dry. While the exact drying time depends on factors such as temperature, humidity, and the thickness of the sealant applied, RTV typically needs 24 hours for a full cure, and rarely takes longer than 72 hours.

To ensure a successful gasket installation, it is crucial to follow the manufacturer's recommendations and use RTV only where necessary. Applying RTV in the wrong areas can cause permanent damage to the gasket, such as over-compression and splitting, or cause the gasket to slide out of place. Remember that a little RTV goes a long way, and it is important to allow adequate time for the RTV to dry before rushing the job.

Brussels' Best Cookware Shops

You may want to see also

RTV needs 24 hours for a full cure

RTV, or Room Temperature Vulcanizing, is a type of sealant used in various automotive applications, including oil pan gaskets. While it is effective in sealing joints and preventing leaks, it is important to allow adequate cure time for RTV to ensure a durable and reliable seal.

When using RTV for sealing oil pan gaskets, it is crucial to follow the manufacturer's instructions and recommendations for cure time. In most cases, RTV requires a full 24 hours to achieve a complete cure. During this period, the RTV undergoes a chemical process, transforming from a malleable state to a hardened, rubber-like material that can withstand the extreme conditions of an engine.

The 24-hour cure time for RTV is essential for several reasons. Firstly, it allows the sealant to reach its maximum bonding strength, ensuring a robust and long-lasting seal. This is particularly important for oil pan gaskets, as they are constantly exposed to oil, coolant, and other fluids, as well as extreme temperatures and vibrations. A fully cured RTV seal can withstand these conditions without breaking down or leaking.

Secondly, the 24-hour cure time helps to prevent any potential issues that may arise from RTV seeping into areas where it doesn't belong. RTV is applied as a bead along the mating surfaces of the gasket. As the parts are assembled and tightened, the RTV spreads out and fills any gaps or irregularities. However, if the RTV has not fully cured, it may continue to flow and migrate to other areas, potentially causing blockages or interference with moving parts.

By allowing the RTV to cure for the full 24 hours, you can be confident that the sealant has set properly and will not leak or cause any unexpected problems. This is a critical step in ensuring the reliability and longevity of the repair. While it may seem like a long wait, especially for time-constrained professionals, it is a necessary step to ensure the integrity of the seal and prevent future issues.

In some cases, certain RTV products or application-specific formulations may have different cure times. For example, Permatex offers The Right Stuff, an RTV product that can be returned to service immediately or within a shorter timeframe. However, for most standard RTVs, the 24-hour cure time is essential for optimal performance and durability.

Loaf Pan Fill Weight: How Much?

You may want to see also

Frequently asked questions

RTV should only be used on the corners of the gasket and/or stepped casting areas that have a gap. It is not necessary to use RTV on the entire gasket.

RTV is used as a supplemental sealer to fill in gaps and ensure a leak-free assembly. It is not a replacement for the gasket but rather an additional layer of protection.

Yes, it is recommended to apply RTV to the corners and stepped areas, such as where the timing cover meets the block and/or oil pan, or where the RMB journal and timing cover journal meet the oil pan side rails.